Low-intensity and high-strength unclassified-tailing slurry filling system

A high-strength, full-tailings technology, used in fillings, safety devices, clay preparation devices, etc., can solve problems such as increasing equipment and energy consumption, increasing pipeline transportation resistance or releasing pressure, and increasing engineering and material consumption. Reasonable design, defoaming enhanced filling, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

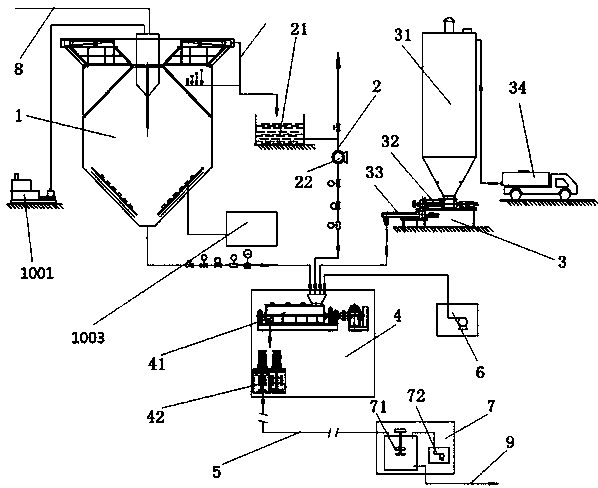

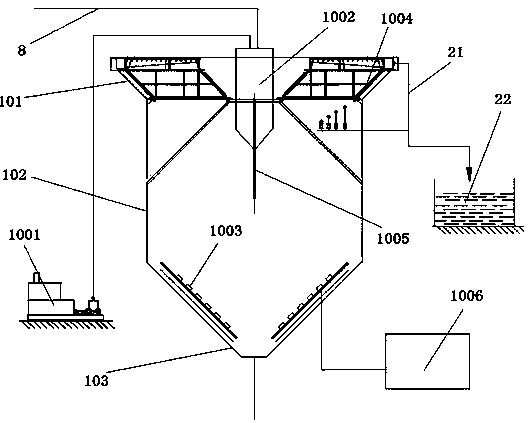

[0027] The low-density high-strength full tailings slurry filling system will be further described below in conjunction with the accompanying drawings and examples. The present invention includes a tailings concentration device, a cement addition device 3, a concentrated water addition device 2, a slurry preparation device 4 and pipelines The conveying device 5, the tailings thickening device, the cement adding device 3 and the concentrated water adding device 2 are respectively connected to the slurry preparation device 4, and the bottom of the slurry preparation device 4 is connected to the pipeline conveying device 5; it also includes a modified low-density adding device 6 and the modified enhanced adding mixing device 7; the modified low density adding device 6 is arranged between the slurry preparation device 4 and the pipeline conveying device 5, and the modified enhanced adding mixing device 7 is arranged at the outlet end of the pipeline conveying device 5; The modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com