A clay sculpture printer that is easy to clean

A printer and clay sculpture technology, applied to ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems of labor-intensive labor, complicated production, and adhesion to the inner wall, and achieve the effect of avoiding disassembly and cleaning and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

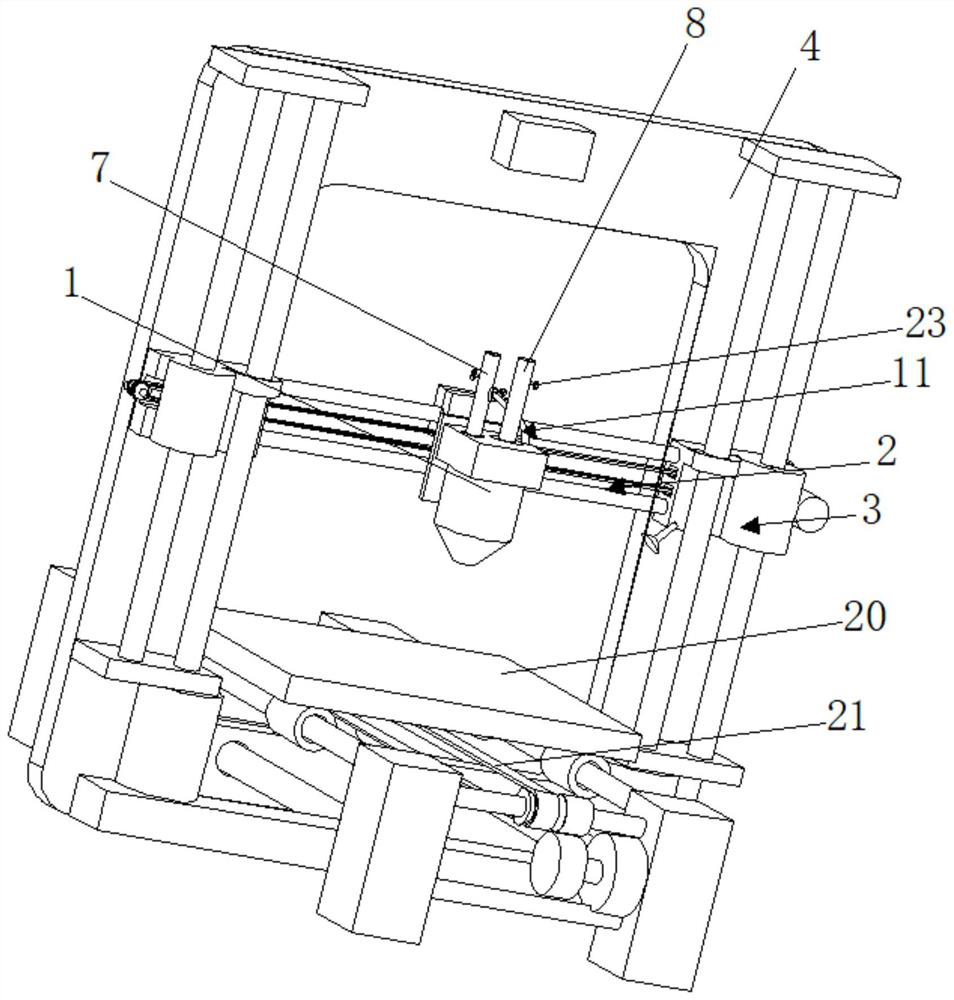

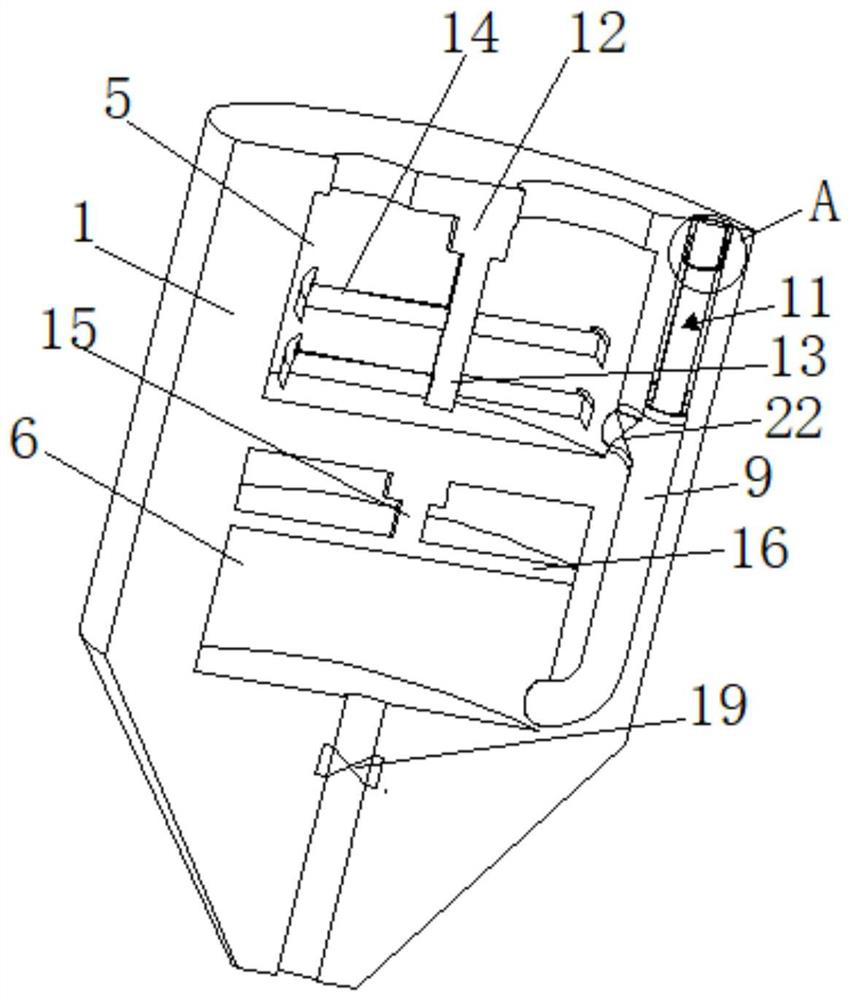

[0030] refer to figure 1 , figure 2 , image 3 and Figure 6 , a clay sculpture printer that is easy to clean, comprising a plastic injection head 1, a horizontal adjustment mechanism 2, a vertical adjustment mechanism 3 and a fixed frame 4, the horizontal adjustment mechanism 2 and the vertical adjustment mechanism 3 are connected to the fixed frame 4, and the horizontal The adjustment mechanism 2 is connected with the plastic injection head 1, and the inner cavity of the plastic injection head 1 is divided into a mixing bin 5 and a discharge bin 6 through a partition. The top of the plastic injection head 1 is connected with a water pipe 7 and a mud pipe 8, and the water pipe 7 and the mud pipe The pipes 8 all extend into the mixing bin 5, and a feeding channel 9 is connected between the mixing bin 5 and the discharging bin 6, and a cleaning channel 10 is also provided on the plastic injection head 1, and the cleaning channel 10 and the feeding channel 9 In communication...

Embodiment 2

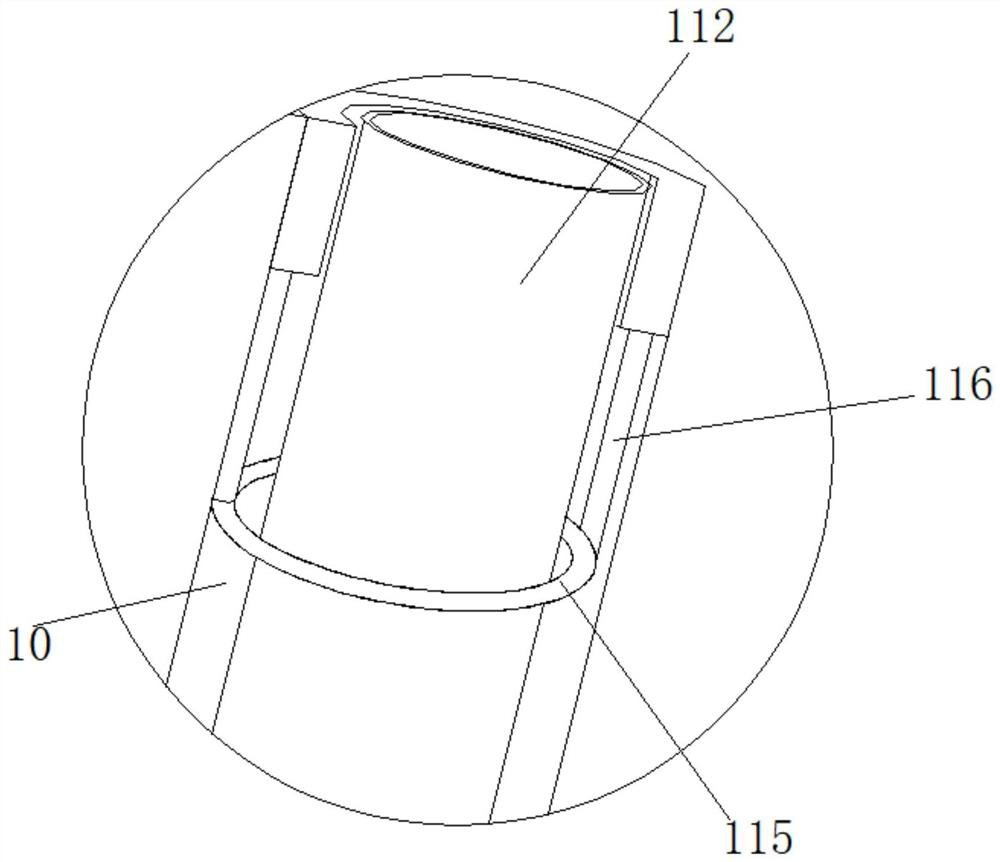

[0037] refer to figure 1 , figure 2 , image 3 and Figure 6, a clay sculpture printer that is easy to clean, is basically the same as Embodiment 1, and furthermore, a cleaning plate 117 is connected to the outer wall of the connecting head 113, and a spring 118 is connected between the connecting head 113 and the cleaning plate 117, and the cleaning plate 117 The side away from the spring 118 is connected with uniformly distributed metal brush filaments. During the movement of the straight water pipe 112 in the cleaning channel 10, the cleaning plate 117 on the outside of the connector 113 is squeezed by the spring 118 to contact with the material delivery channel 9. The inner walls of the cylinders are offset against each other, combined with the water flowing out of the nozzle 114, the function of further cleaning the material delivery channel 9 is realized, which avoids the disassembly and cleaning of the clay sculpture printer, improves the cleaning efficiency and the ...

Embodiment 3

[0039] refer to figure 1 , figure 2 and Figure 5 , a clay sculpture printer that is easy to clean, the mixing bin 5 and the discharge bin 6 are respectively connected with a stirring mixing mechanism and an extrusion mechanism, the stirring and mixing mechanism includes a stirring motor 12, and the output end of the stirring motor 12 is connected with a stirring rod 13, Stirring blades 14 are connected to the outer wall of the stirring rod 13 , and the extrusion device includes a hydraulic telescopic rod 15 and an extrusion plate 16 , and the hydraulic telescopic rod 15 is connected to the center of the extrusion plate 16 .

[0040] Stirring blade 14 comprises sleeve pipe 141 and sleeve rod 142, and sleeve rod 141 is inserted in the sleeve pipe 142, is connected with adjusting spring 143 between the insertion end of sleeve rod 142 and sleeve pipe 141 inner wall, and sleeve pipe 141 is connected on stirring rod 13 , an arc-shaped plate 144 is connected to the end of the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com