Glass noodle collection tray automatic cutter

A technology for collecting trays and fans, applied in metal processing and other directions, can solve the problems of low operation efficiency, high labor intensity, complicated movements, etc., and achieve the effect of reducing operation steps, convenient and fast use, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

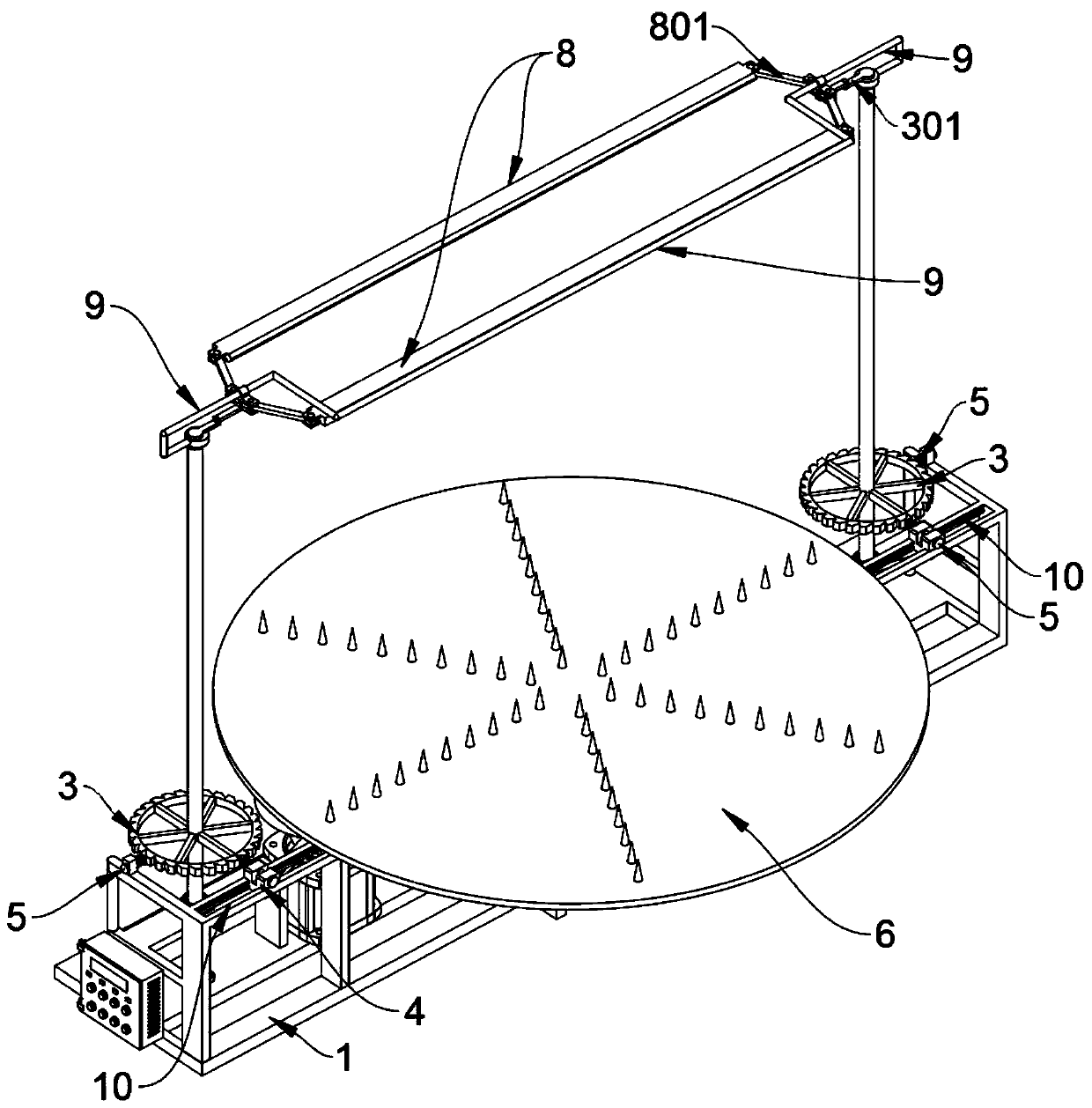

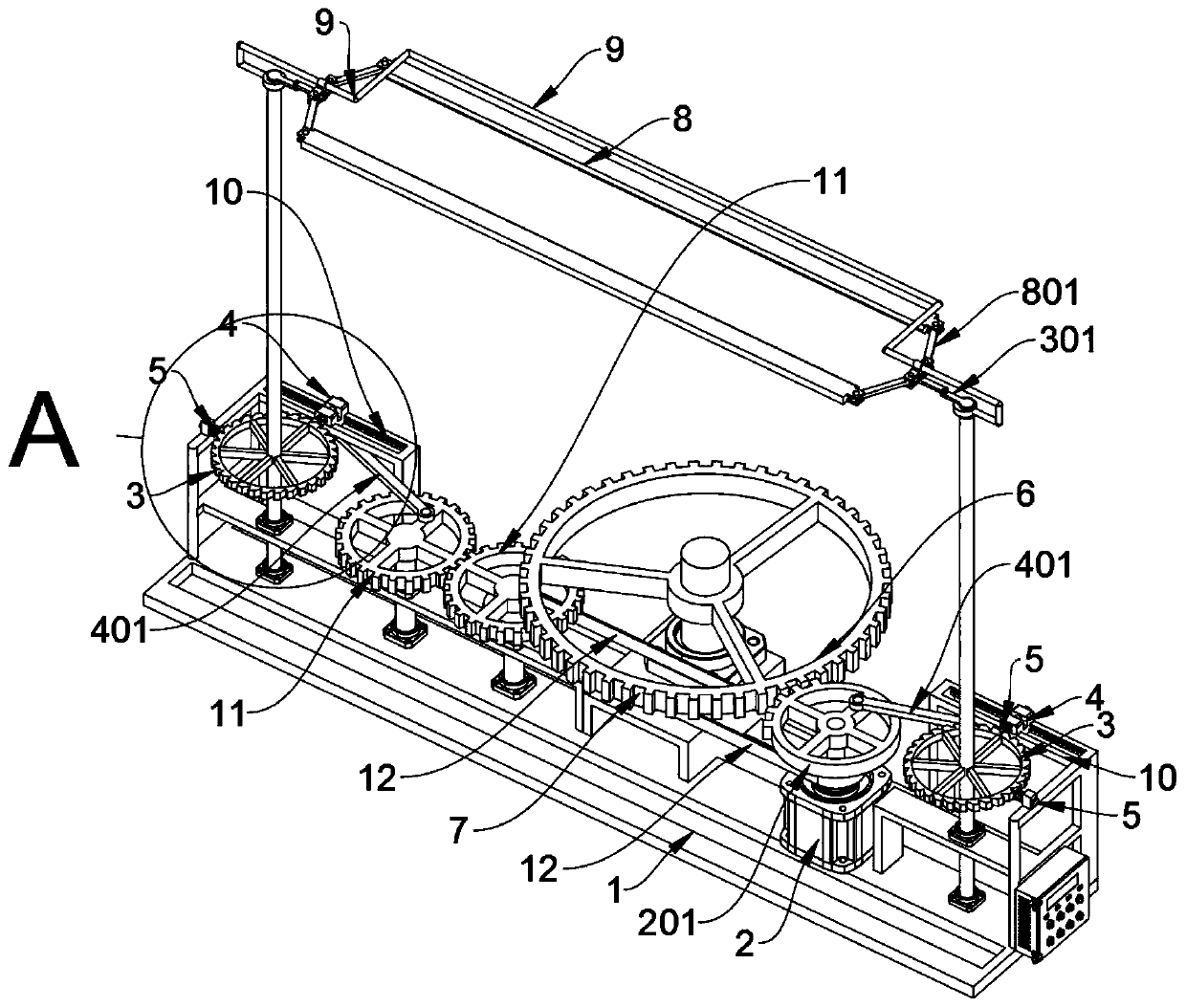

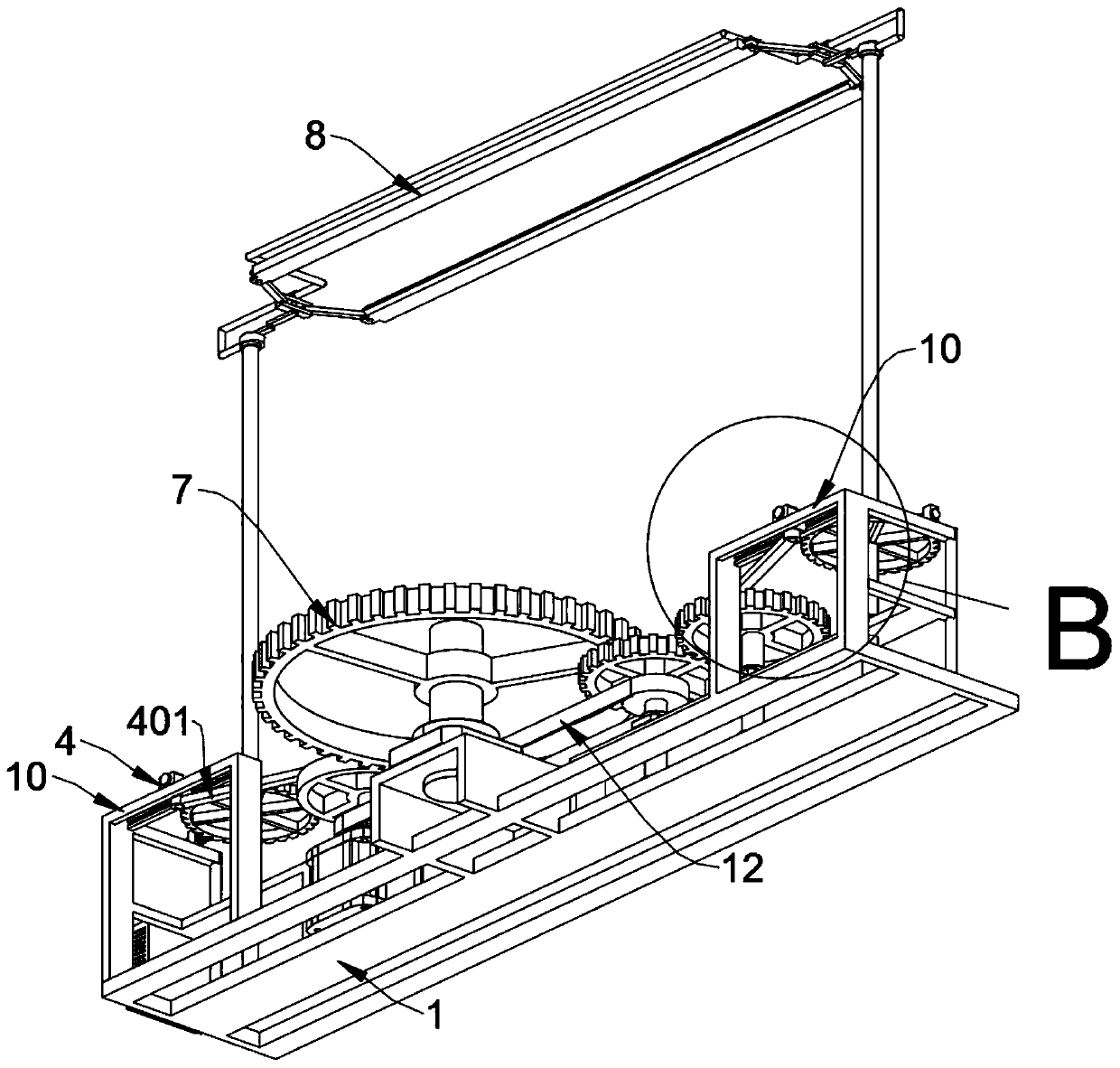

[0030] See Figure 1 to Figure 9 , An embodiment provided by the present invention: a fan collecting tray rotation cutter, including a base 1, a shearing plate 8, a positioning frame 9 and a driven gear 11, the base 1 is arranged in a rectangular shape as a whole, and the middle rear There is a central gear 7 in the lateral position. The top of the shaft of the central gear 7 is welded and fixed to a tray 6, and a motor 2 is also locked and installed on the base plate at the right side of the central gear 7; the left and right sides of the base 1 The outer eaves are symmetrically rotated and supported by two shift gears 3. The rear position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com