A hydraulic mechanical rust removal device and process for the inner wall of a special-shaped small-diameter pipe

A small-diameter pipe and mechanical derusting technology, which is applied to machine tools for surface polishing, machine tools suitable for grinding the edge of workpieces, manufacturing tools, etc., can solve problems such as poor effects, and achieve good effects of protecting oil cylinders and derusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

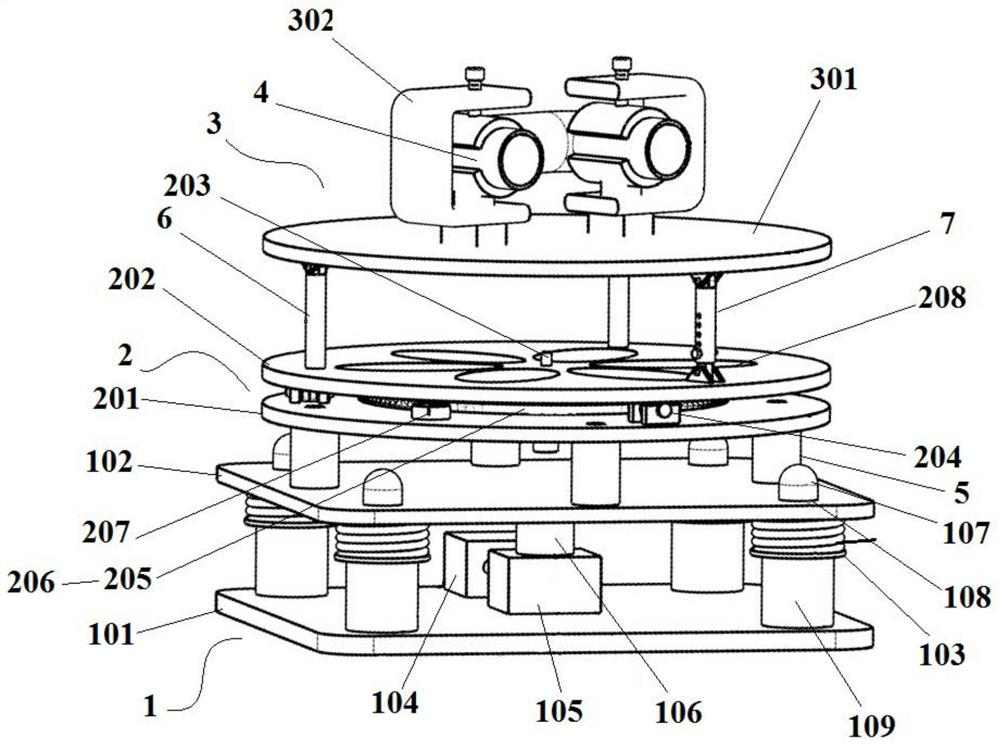

[0044] Comply with the above technical solutions, such as figure 1 and figure 2 As shown, this embodiment provides a hydraulic mechanical rust removal device for the inner wall of a special-shaped small-diameter tube, including a vibration mechanism 1, a rotation mechanism 2 and an installation mechanism 3;

[0045] Vibration mechanism 1 comprises base 101 and top seat 102, and base 101 is fixedly installed with the bottom end of a group of support columns 109 near the edge, and the top of each support column 109 is equipped with the bottom end of protection spring 103 respectively, and a group of protection The top of the spring 103 is installed on the bottom surface of the top seat 102;

[0046] A hydraulic unit is installed in the middle of the base 101, and the hydraulic unit includes a hydraulic source 104. The hydraulic source 104 is connected to the high-speed reversing solenoid valve 105, and the high-speed reversing solenoid valve 105 is connected to the oil cylinde...

Embodiment 2

[0060] This embodiment provides a hydraulic mechanical descaling process for the inner wall of a special-shaped small-diameter pipe. The process adopts the hydraulic mechanical descaling device for the inner wall of a special-shaped small-diameter pipe in Embodiment 1.

[0061] The process specifically includes the following steps:

[0062] Step 1, after filling the abrasive material in the special-shaped small-bore tube 4 and then sealing it, then fixing the special-shaped small-bore tube 4 on the fixing fixture 302, adjusting the rotation rate of the rotating unit 205 and the frequency of the high-speed reversing solenoid valve 105;

[0063] Step 2, start the hydraulic pressure source 104, start the high-speed reversing solenoid valve 105, make the hydraulic mechanical derusting device on the inner wall of the special-shaped small-diameter pipe be in the working state, and derust the inner wall of the special-shaped small-diameter pipe 4 through abrasive materials;

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com