Air-suction vibration disk type field precise seeder for grain

A seeder and vibrating disc technology, applied in seeder parts, sowing, application, etc., can solve the problems of not being suitable for production needs, poor seeding uniformity, and easy occurrence of missed insertion, so as to improve seeding uniformity and operating efficiency, reduce Small suction resistance, enhanced fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

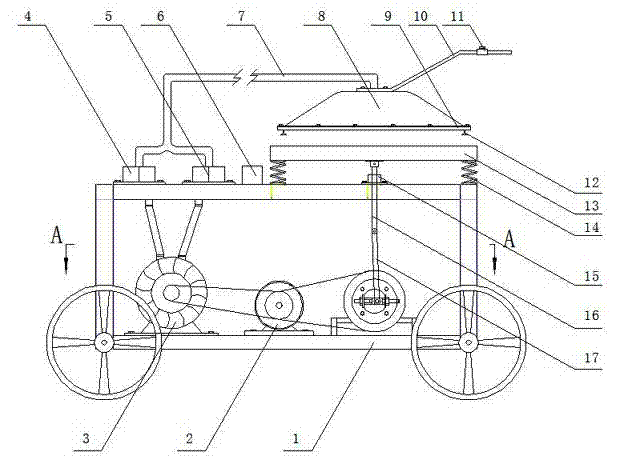

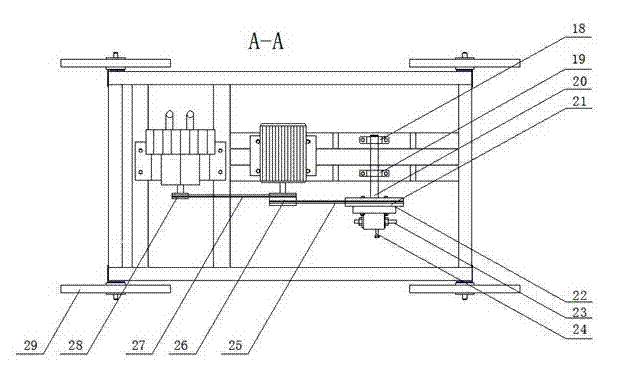

[0014] For device layout and transmission, please refer to figure 1 , figure 2 . Seeder stand 1 is divided into upper and lower layers, small gasoline engine 2 and positive and negative pressure fans 3 are respectively connected to the lower deck of seeder stand 1 by bolts, and the output shaft of small gasoline engine 2 is parallel to the input shaft axis of positive and negative pressure blower 3. The negative pressure port of the positive and negative pressure fan 3 is connected with the air inlet of the electromagnetic reversing valve one 4, the positive pressure port of the positive and negative pressure fan 3 is connected with the air inlet of the electromagnetic reversing valve two 5, and the electromagnetic reversing valve one 4 Connect with the top of the suction cup cover 8 through the hose 7 and the air outlet of the electromagnetic reversing valve 2, and the suction cup panel 9 is connected to the bottom of the suction cup cover 8 by bolts to form a closed cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com