Touch-type manicure baking lamp control circuit

A control circuit and touch-type technology, which is applied in the direction of energy-saving control technology, electric light source, electrical components, etc., can solve the problems of cumbersome button operation and inability to set various baking times, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

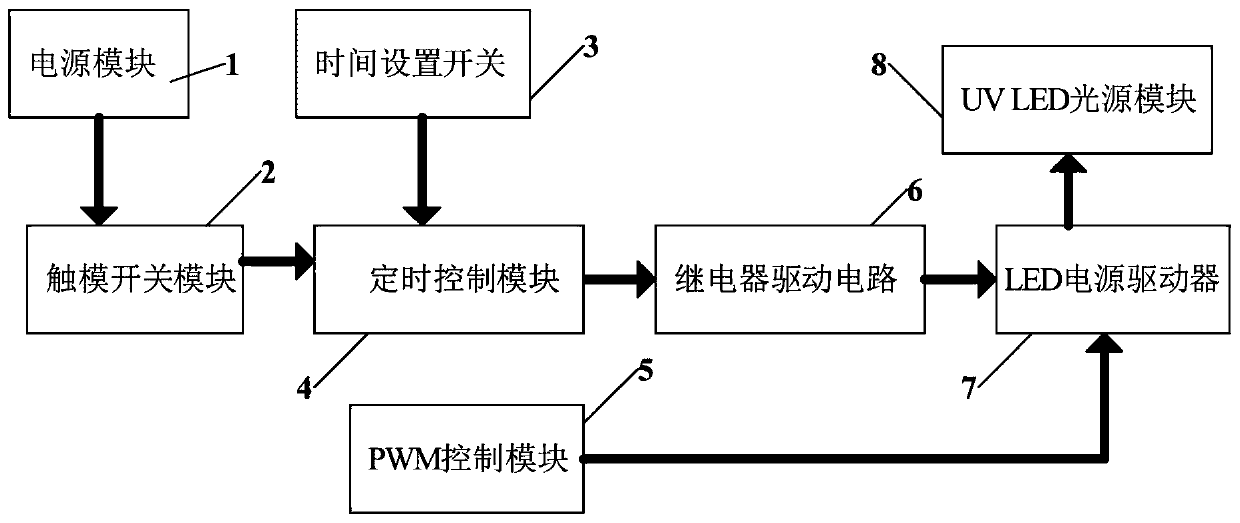

[0019] A touch control circuit for manicure lamps, such as Figure 1-2 As shown, it includes a power supply module 1, a touch switch module 2, a relay drive circuit 6, an LED power driver 7 and a UVLED light source module 8, and the output end of the touch switch module 2 is connected to the input end of the relay drive circuit 6, so The touch switch module 2 is used to control the switch of the relay drive circuit 6, the output end of the relay drive circuit 6 is connected to the input end of the LED power driver 7, and the output end of the LED power driver 7 is connected to the UVLED light source module 8 The input terminal of the relay drive circuit 6 controls the switch of the UVLED light source module 8, and the power supply module 1 supplies power for the touch switch module 2, the relay drive circuit 6 and the LED power driver 7.

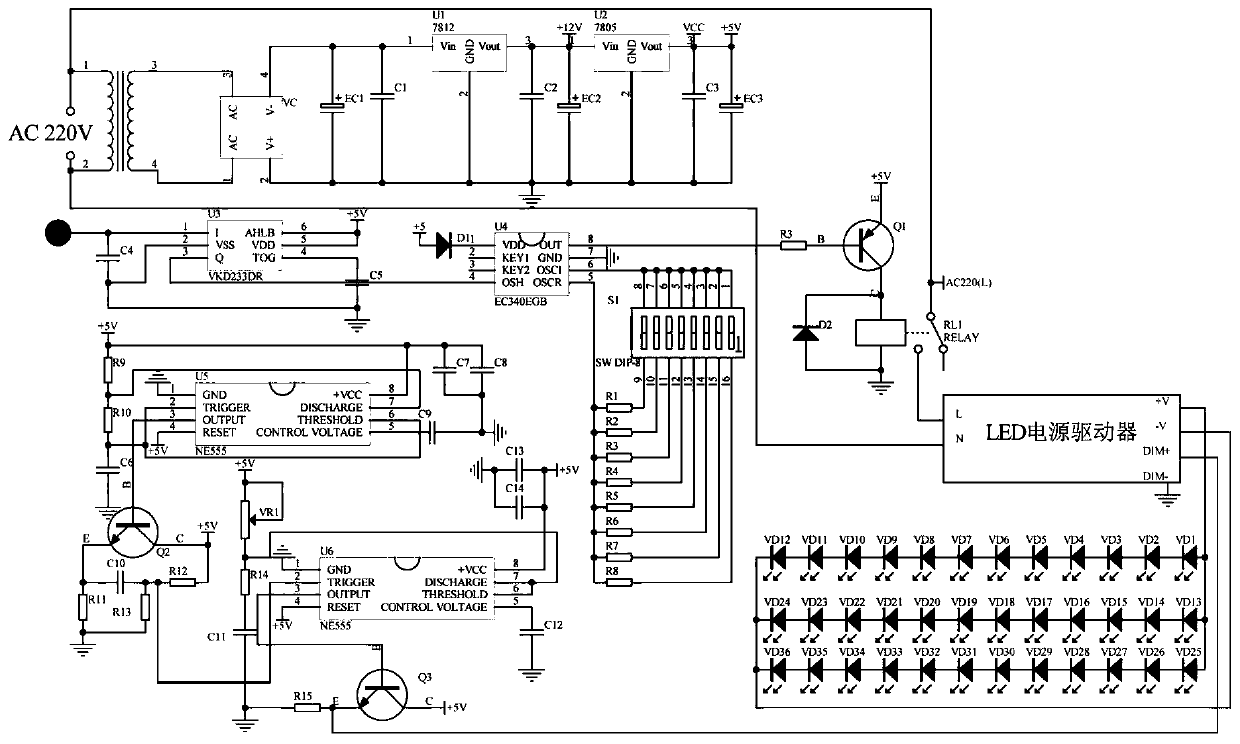

[0020] The power module 1 is stepped down by a 220-volt alternating current through a 12V output transformer, and the low-voltage alternati...

Embodiment 2

[0025] A touch control circuit for manicure lamps, such as Figure 1-2 As shown, also include time setting switch 3 and timing control module 4, the input end of described timing control module 4 is connected with the output end of touch switch module, the output end of described timing control module 4 is connected with the input of relay drive circuit 6 terminal connection, the time setting switch 3 is connected with the timing control module 4, the time setting switch 3 is used to set the length of time, and the timing control module 4 realizes the time control of 8 gears through the time setting switch 3, The power supply module 1 supplies power for the time setting switch 3 and the timing control module 4 .

[0026]The time setting switch 3 includes a dial switch S1 and resistors R1-R8, one end of the dial switch S1 is connected in parallel with the 6 pins of the EC340EGB, and the other end pins of the dial switch S1 are respectively connected with the resistors R1-R8 one...

Embodiment 3

[0030] A touch control circuit for manicure lamps, such as Figure 1-2 As shown, a PWM control module 5 is also included, the output end of the PWM control module 5 is connected to the input end of the LED power driver 7, the PWM control module 5 includes an oscillator and a PWM dimming circuit, and the PWM control module 5 realizes the current adjustment of the LED power driver 7, thereby realizing the dimming of the UVLED light source module 8.

[0031] The PWM control module 5 includes an oscillator and a PWM dimming circuit. After the oscillator is powered on, the power supply Vcc charges the capacitor C6 through R9 and R10. When Uc<1 / 3Vcc, the oscillator outputs OUTPUT=1, Transistor Q2 is cut off. When Uc is charged to be greater than or equal to 2 / 3Vcc, the oscillator output OUTPUT is reversed to 0, and the transistor Q2 is turned on at this time, so that the discharge terminal is grounded, and the capacitor C6 is discharged to the ground through R10, so that Uc drops. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com