Stator and rotor punching production line

A production line, stator and rotor technology, applied in the manufacture of stator/rotor bodies, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, achieve the effects of improving production and processing efficiency, facilitating subsequent processes, and ensuring smooth cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

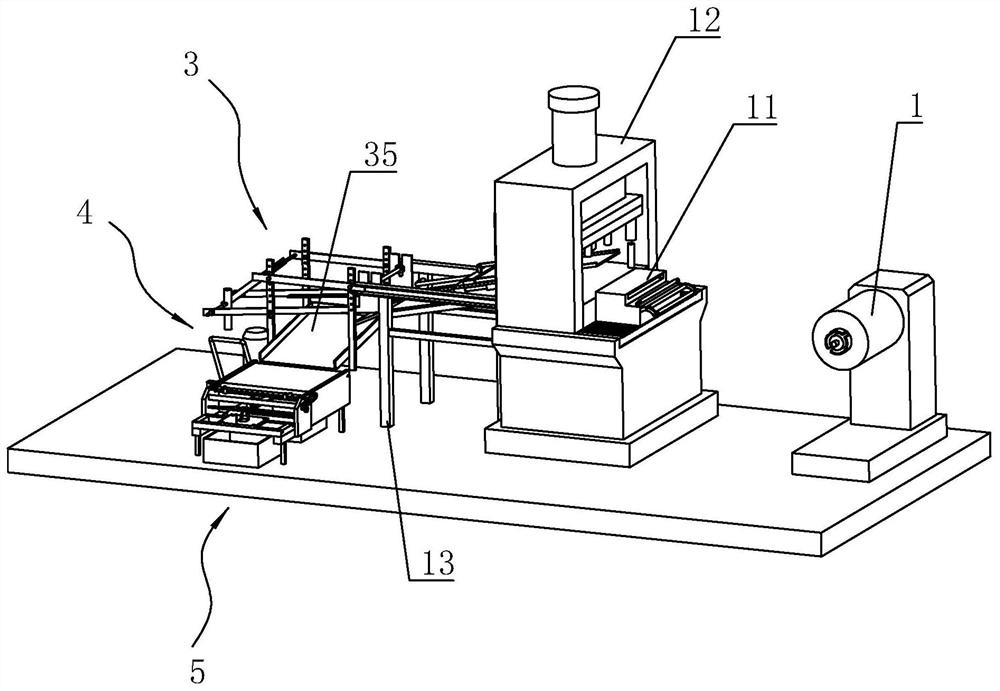

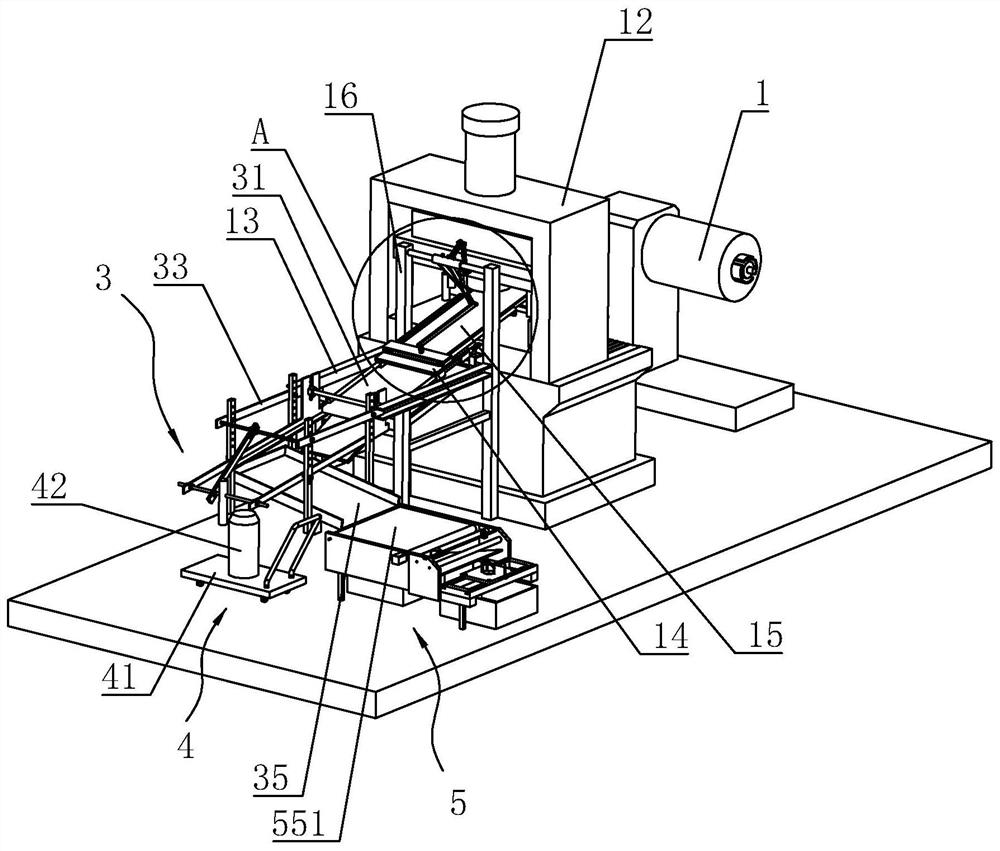

[0042] Embodiment: a kind of stator and rotor stamping production line, such as figure 1 As shown, it includes an uncoiler 1, a yaw feeder 11, a punching machine 12, a base frame 13, a sorting device 3, a first receiving device 4 for collecting stator punches, and a vertically perpendicular to the sorting The device 3 is distributed and used to collect the second receiving device 5 of the rotor punch, and the yaw feeder 11 is installed on the punching machine 12 .

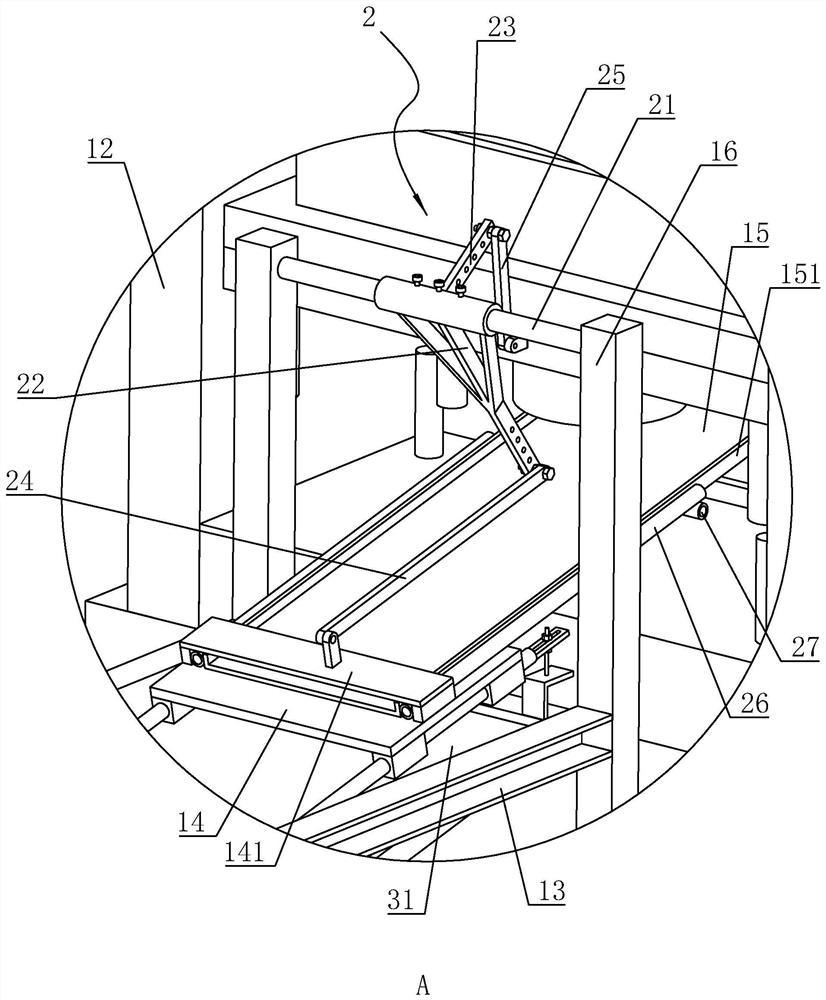

[0043] Such as figure 2 and image 3 As shown, the base frame 13 is fixed on the ground and is located beside the punching machine 12, and the length direction of the base frame 13 is perpendicular to the punching machine 12, and the base frame 13 is provided with a vertical stand 16 near the end of the punching machine 12, standing The frame 16 is provided with a link mechanism 2; the link structure includes a rotating shaft 21 that is rotatably connected in the stand 16, the axis of the rotating shaft 21 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com