Lithium iron phosphate battery, electrolyte and manufacturing method of lithium iron phosphate battery

A lithium iron phosphate battery and electrolyte technology, which is applied in the field of lithium iron phosphate battery, electrolyte and lithium iron phosphate battery preparation, can solve the problems of chemical block battery short circuit, accelerated battery attenuation, explosion, etc., to reduce internal impedance , prolong service life and high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

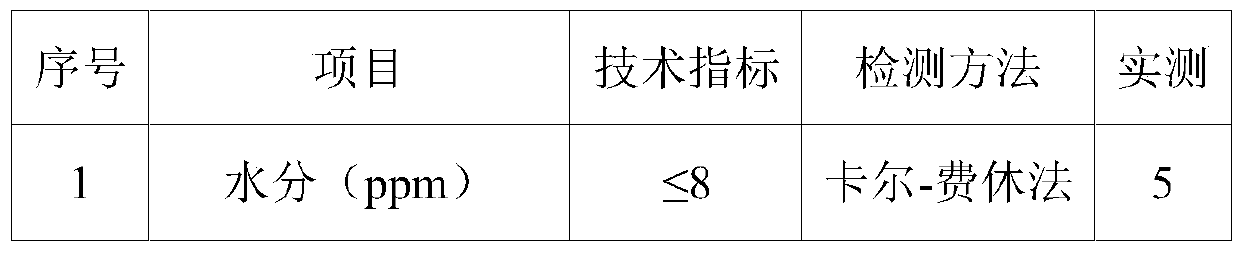

[0029] This embodiment provides an electrolyte, a lithium iron phosphate battery containing the electrolyte, and a method for preparing the lithium iron phosphate battery. Specifically, the preparation method for the lithium iron phosphate battery includes the following steps:

[0030] (1) According to the mass fraction, weigh the following components: ethylene carbonate 35.4%, ethyl methyl carbonate 35%, dimethyl carbonate 15%, propylene carbonate 3%, lithium hexafluorophosphate 10%, propane sultone 0.5% %, vinylene carbonate 1%, and lithium difluorooxalate borate 0.1%; these weighed components are mixed evenly to obtain an electrolyte solution for future use.

[0031] (2) First weigh 60kg of lithium iron phosphate, 0.5kg of polyvinylidene fluoride, 0.5kg of conductive agent, and 60kg of N-methylpyrrolidone for later use; The above-mentioned polyvinylidene fluoride needs to be baked at a temperature of 105°C for 3 hours before weighing, and the above-mentioned conductive agen...

Embodiment 2

[0038] This embodiment provides an electrolyte, a lithium iron phosphate battery containing the electrolyte, and a method for preparing the lithium iron phosphate battery. Specifically, the preparation method for the lithium iron phosphate battery includes the following steps:

[0039] (1) According to the mass fraction, weigh the following components: ethylene carbonate 24%, ethyl methyl carbonate 20%, dimethyl carbonate 25%, propylene carbonate 7%, lithium hexafluorophosphate 18%, propane sultone 2 %, 3% vinylene carbonate, and 1% lithium difluorooxalate borate; mix these weighed components evenly to obtain an electrolyte solution for later use.

[0040] (2) First weigh 40kg of lithium iron phosphate, 4kg of polyvinylidene fluoride, 4kg of conductive agent, and 40kg of N-methylpyrrolidone for later use; Baking at 105°C for 3 hours before weighing the above-mentioned polyvinylidene fluoride, and baking at 120°C for 4 hours before weighing the above-mentioned conductive agent,...

Embodiment 3

[0047] This embodiment provides an electrolyte, a lithium iron phosphate battery containing the electrolyte, and a method for preparing the lithium iron phosphate battery. Specifically, the preparation method for the lithium iron phosphate battery includes the following steps:

[0048] (1) According to the mass fraction, weigh the following components: ethylene carbonate 33.4%, ethyl methyl carbonate 30%, dimethyl carbonate 18%, propylene carbonate 4%, lithium hexafluorophosphate 12%, propane sultone 0.8 %, vinylene carbonate 1.5%, and lithium difluorooxalate borate 0.3%; these weighed components are mixed evenly to obtain an electrolyte solution for future use.

[0049] (2) First weigh 55kg of lithium iron phosphate, 1kg of polyvinylidene fluoride, 1kg of conductive agent, and 50kg of N-methylpyrrolidone for later use; Baking at 105°C for 3 hours before weighing the above-mentioned polyvinylidene fluoride, and baking at 120°C for 4 hours before weighing the above-mentioned co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com