Assembling method for NbTi multi-core superconducting ingot blank

An assembly method and superconducting technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of time-consuming and laborious loss, and the difficulty of NbTi hexagonal rods passing through oxygen-free copper tubes. Achieve the effects of reducing labor intensity, wide applicability and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Assembly method of NbTi multi-core superconducting billet of the present invention

[0029] The invention provides a method for assembling a NbTi multi-core superconducting ingot, said method comprising the following steps:

[0030] (1) Clean the oxygen-free copper tube 6 with a diameter of Φ30-70mm for assembly, a tube wall thickness of 3-10mm, and a length of 3-10m, and take a hexagonal NbTi single mandrel 4 with a distance between H3.0-H9.0mm After cleaning.

[0031] (2) Place the cleaned oxygen-free copper tube 6 on the working platform 8, arrange the cleaned hexagonal NbTi single mandrel 4 neatly according to the designed cross-section, and fix it with cable ties.

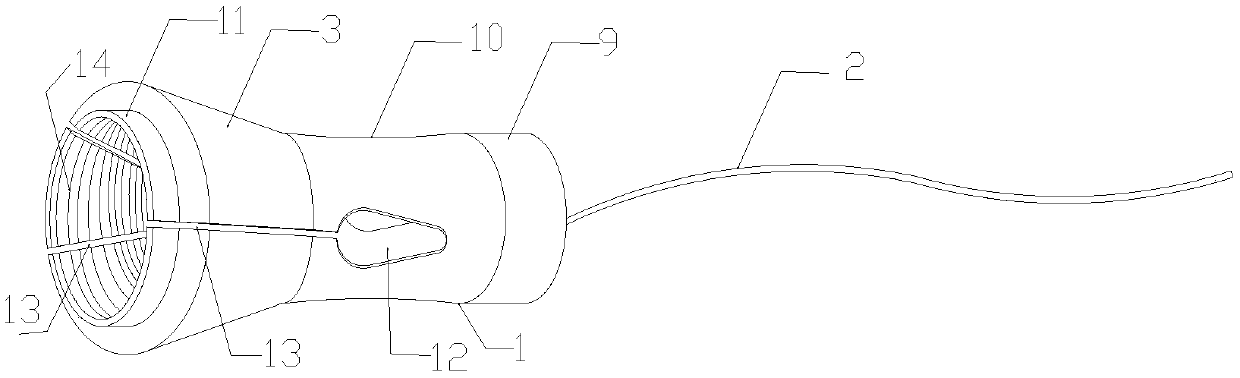

[0032] (3) The 100-200 mm head portion of the neatly arranged NbTi single mandrel 4 is covered with a copper tube 16 of a suitable size for swaging to form the head.

[0033] (4) Pass the traction tool 5 through the oxygen-free copper tube 6 for assembly, connect the copper tube 16 socke...

Embodiment 2

[0036] Embodiment 2: The assembly method of the NbTi multi-core superconducting ingot of the present invention

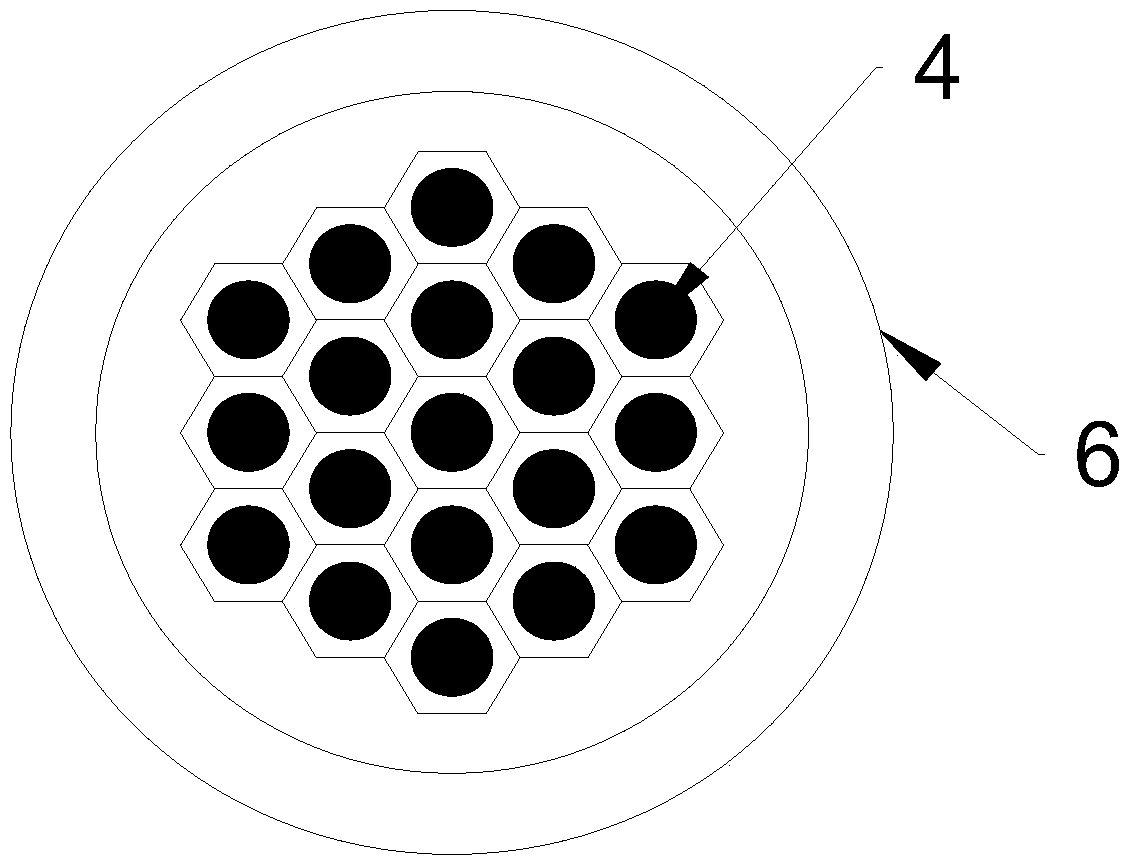

[0037] Clean the hexagonal NbTi single mandrel 4 with a diameter of H8.0mm and a length of 6m and the oxygen-free copper tube 6 with a diameter of Φ52mm, a wall thickness of 5mm and a length of 6m. After cleaning, the oxygen-free copper tube 6 is placed in the working on platform 8. Then the NbTi single mandrel 4 with a diameter of H8.0mm and a length of 6m is attached according to the instructions. figure 2 Place the cross-sectional structure shown, and fix it with plastic cable ties after placing it neatly. The head of the NbTi single mandrel 4 is covered with a copper tube 16 with a length of 200 mm, a diameter of 48 mm, and a wall thickness of 3 mm. Machine rotary forging NbTi single mandrel with 4 heads covered with 16 parts of copper tube to Φ35mm. Extend the traction tool 5 through the oxygen-free copper tube 6, and clamp the part of the copper tube 16 tha...

Embodiment 3

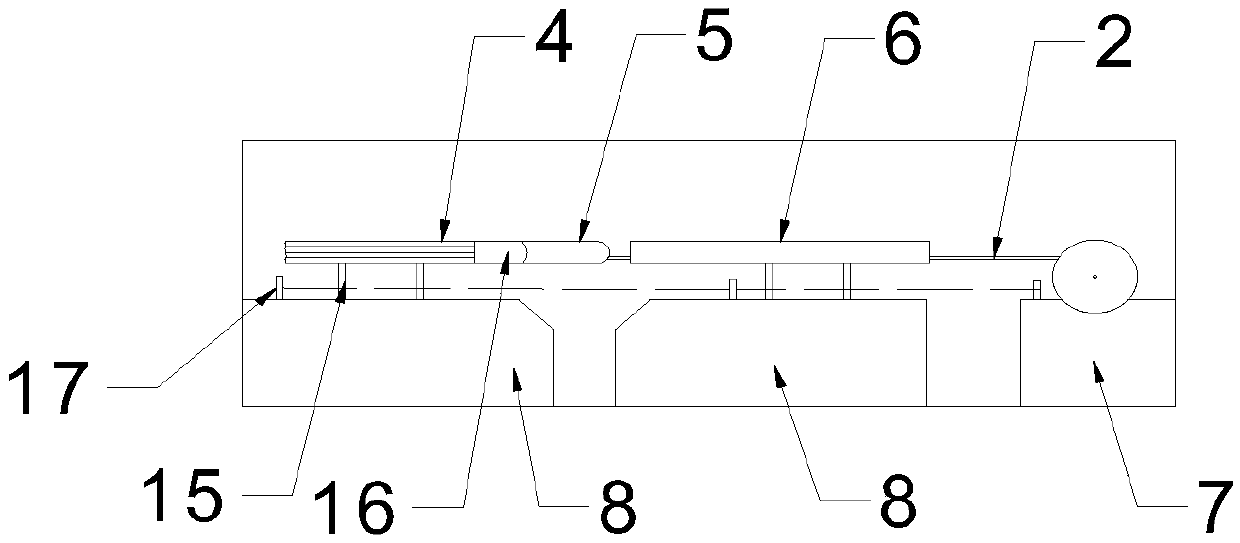

[0038] Embodiment 3: The method for placing the oxygen-free copper tube and the NbTi single core rod on the workbench of the present invention

[0039] As attached to the manual image 3 As shown, in the present invention, there are two working platforms 8, and the NbTi single mandrel 4 that is neatly placed and the length of the head cover is 100-200m copper pipe 16 for swaging the head is placed on a working platform 8, without The oxygen copper pipe 6 is placed on another working platform 8 .

[0040] Preferably, two brackets 15 are arranged on the working platform 8 in the present invention, and the neatly arranged NbTi single core rods 4 and oxygen-free copper tubes 6 are respectively placed on the brackets 15 on the respective working platforms 8 .

[0041] More preferably, the bottom of the four corners of the working platform 8 of the present invention has height-adjusting outriggers, a level is provided on the working platform 8 , and an infrared height correction me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com