Tension-tension fatigue testing device for fiber rod body and fatigue performance evaluation method

A technology of fatigue testing and evaluation methods, which is applied in the direction of measuring devices, using applied repetitive force/pulsation force to test material strength, strength characteristics, etc., can solve the problem of limiting the application of fiber composite rods, lack of pull-pull fatigue testing, and hinder new materials and the application and development of new structures to achieve the effect of a wide range of applications and a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

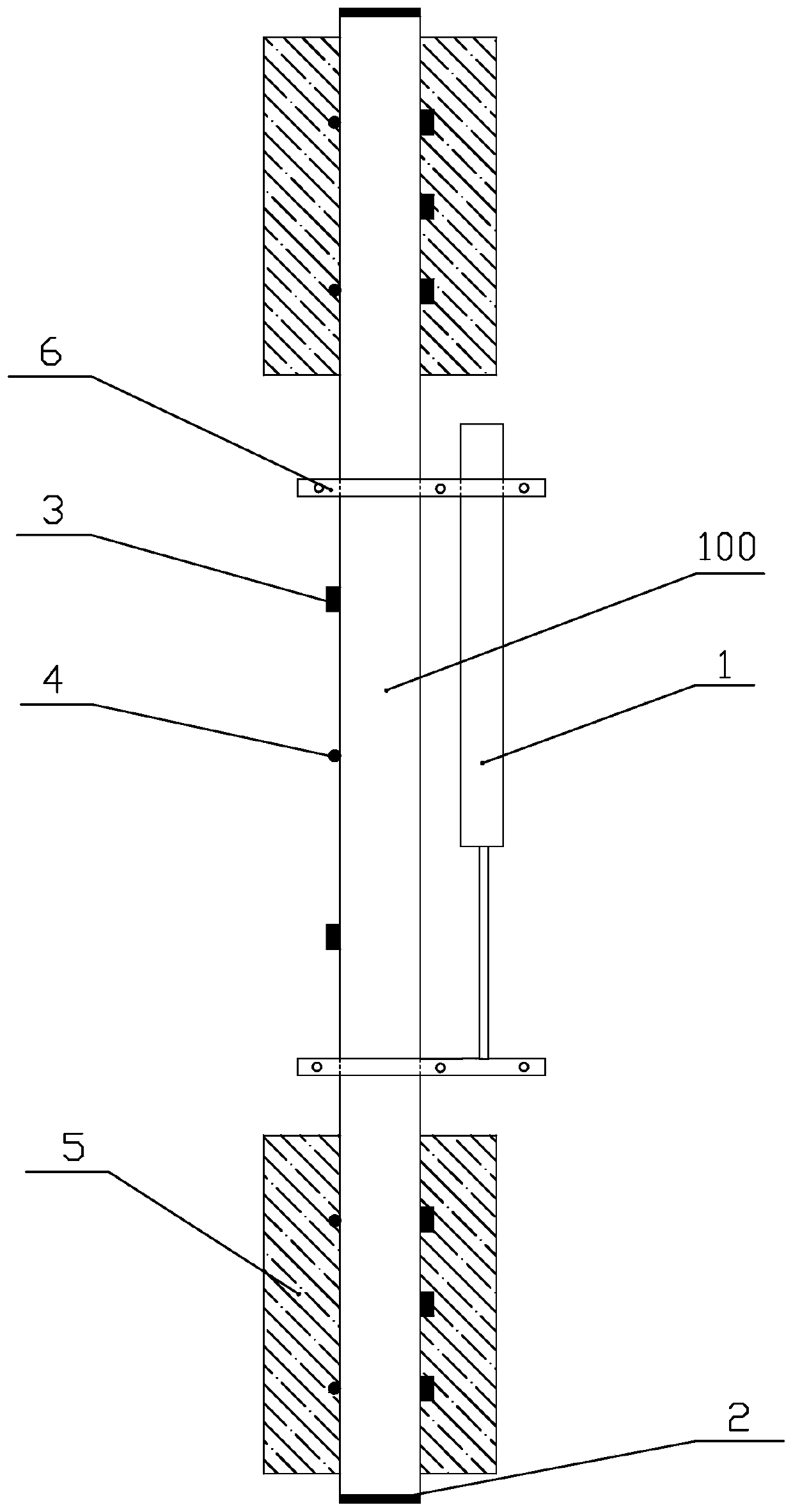

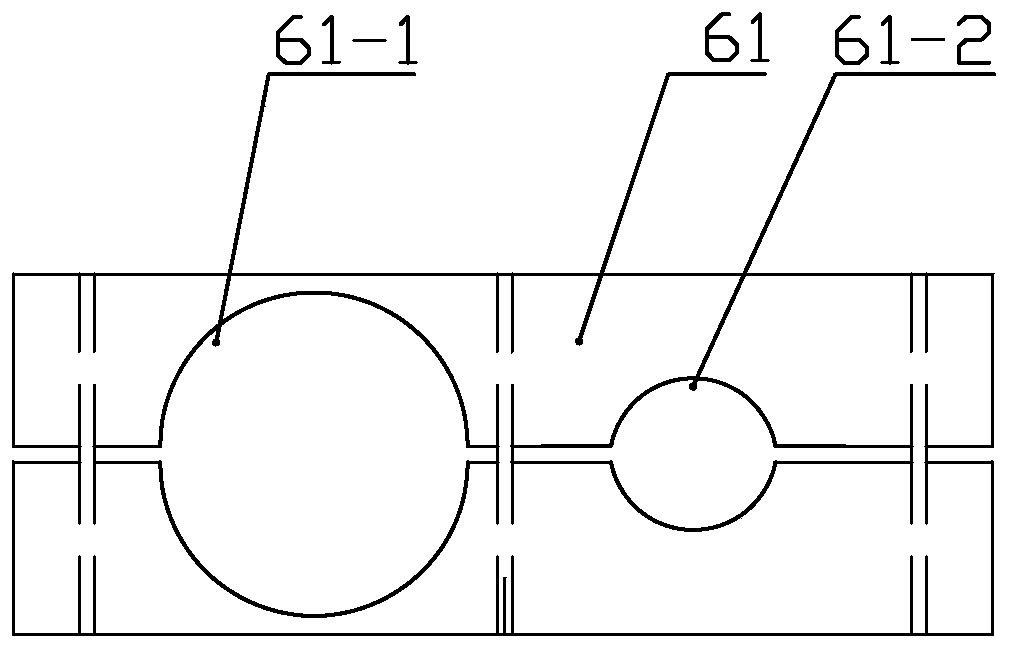

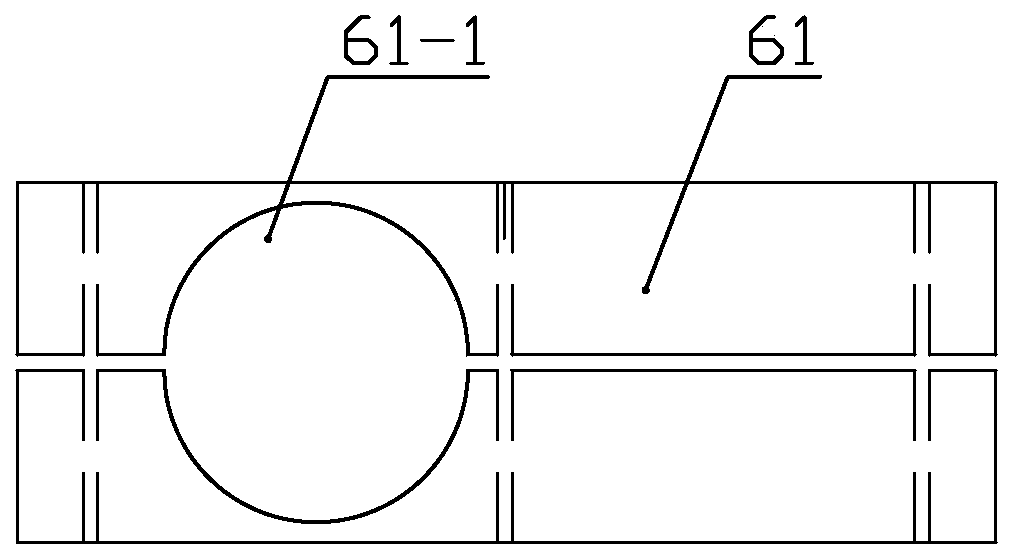

[0033] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, be used for the pull-pull fatigue test device of fiber rod body, it comprises fixing device, displacement sensor 1, piezoelectric sensor 2, strain sensor 3, temperature sensor 4 and anchorage 5, the quantity of described anchorage 5 There are two, the fiber rod body 100 is vertically arranged and its upper and lower parts are respectively anchored by the anchorage 5, the number of the strain sensor 3 and the temperature sensor 4 are several, and are respectively pasted on the surface of the fiber rod body 100, the piezoelectric sensor 2 The quantity is two, and respectively pasted on the two ends of the fiber rod body 100, the displacement sensor 1 is arranged parallel to the fiber rod body 100, and the fixing device includes two positioning plates 6 arranged in parallel up and down, and the two positioning plates 6 Both are fixed on the fiber rod body 100 between the two anchors 5 , the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com