Burner fire cover

A technology for burners and fire caps, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., and can solve problems such as difficulty in cleaning, suboptimal flame stabilization effect, overflow blocking the main fire channel or flame stabilization channel, etc. problem, to achieve the effect of not easy to leave the flame, good flame stabilization effect, and uniform combustion of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

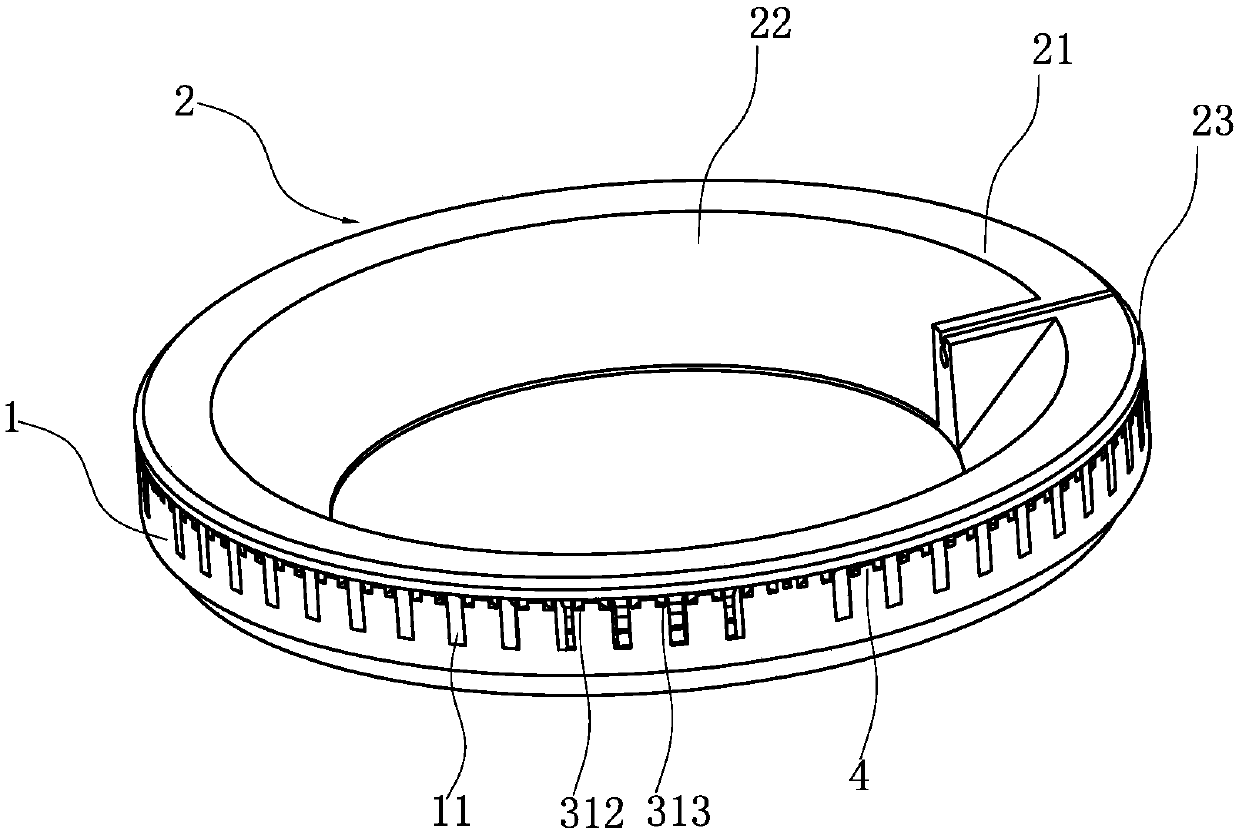

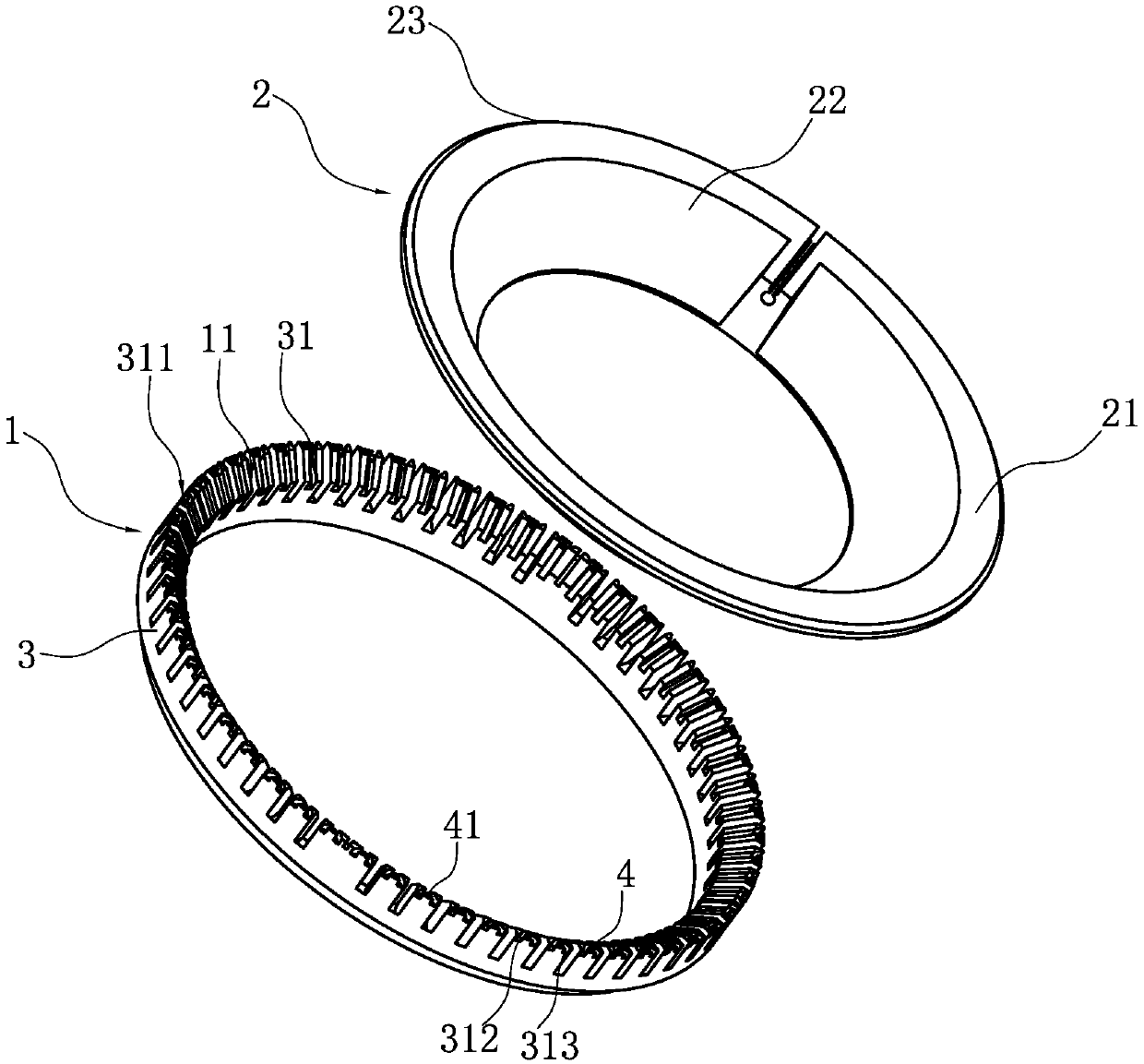

[0028] like Figure 1-8 As shown, it is the best implementation mode of this embodiment. The burner fire cover in this embodiment includes a fire cover body 1 and a cover body 2 covering it. The fire cover body 1 can be in the form of a cylinder with an opening downward. , and can also be ring-shaped. In this embodiment, the ring-shaped fire cover is described as an example. The ring-shaped fire cover can be an outer ring fire cover or an inner ring fire cover. In this embodiment, the outer ring fire cover is mainly described in detail.

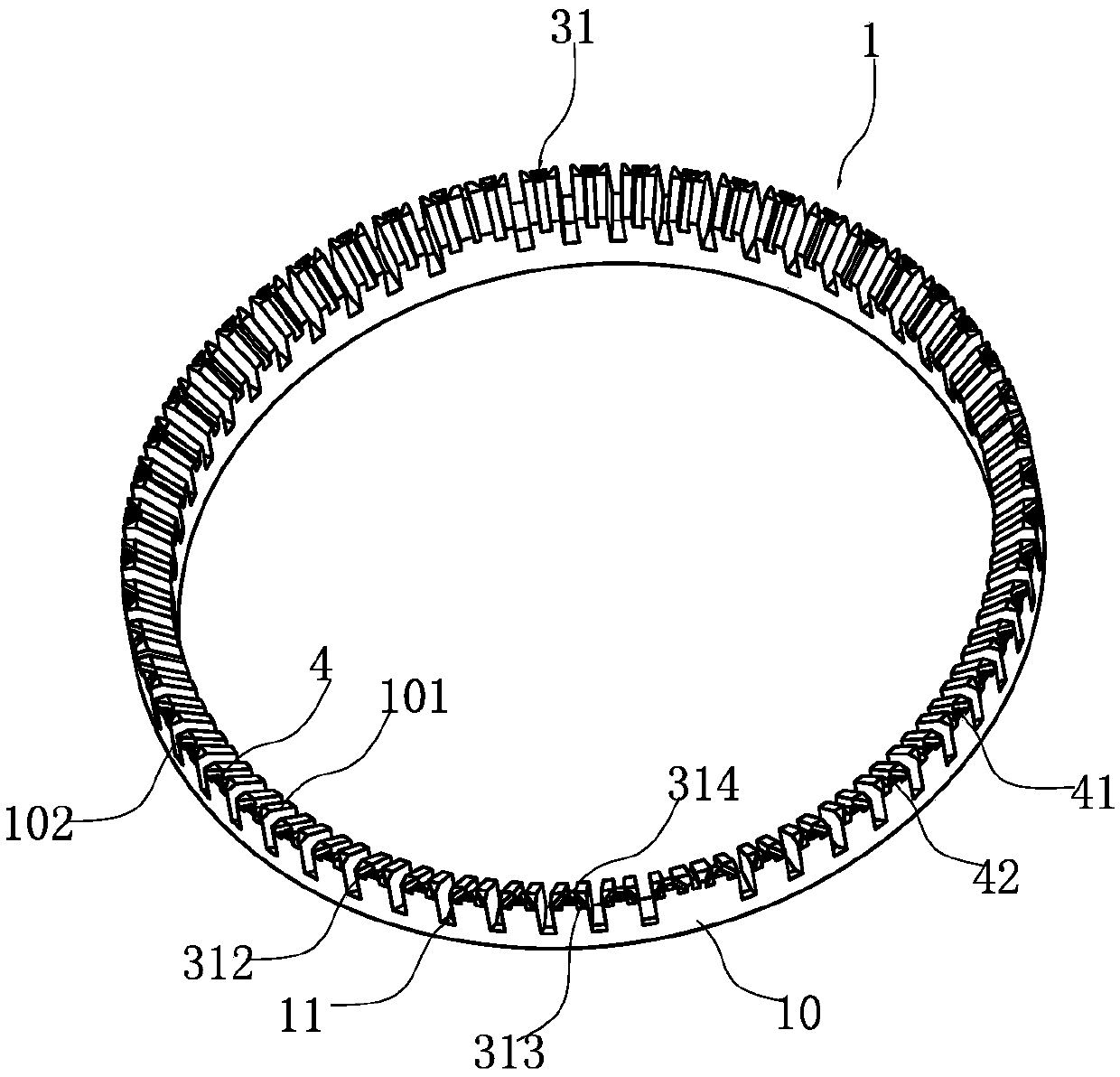

[0029] Wherein, the upper surface of the annular peripheral wall 10 of the fire cover body 1 is formed with radial main fire grooves 11 at intervals along the circumferential direction, and the cover body 2 is annular, and the annular top surface 21 of the cover body 2 is connected with the An inner ring wall 22 and an outer ring wall 23 extending vertically or obliquely downward on the inner edge and the outer edge of the annular top surface...

Embodiment 2

[0035] The structure is basically similar to that of Embodiment 1, the only difference is that the cross-section of the stopper 4 is a rectangular structure, the first sub-flame-stabilizing channel 312 and the second sub-flame-stabilizing channel 313 are arranged symmetrically along the stopper, and the cross-sectional area is from The wedge-shaped fire hole structure gradually increases from inside to outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com