A method for efficient fractionation and separation of organic matter in pulping yellow liquor

A technology for grading separation and organic matter, applied in chemical instruments and methods, water pollutants, multi-stage treatment of water/sewage, etc., can solve the problem of not realizing targeted classification and utilization, achieve the concept of zero-emission environment-friendly industry, and achieve high efficiency The effect of fractionation separation and good precipitation recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

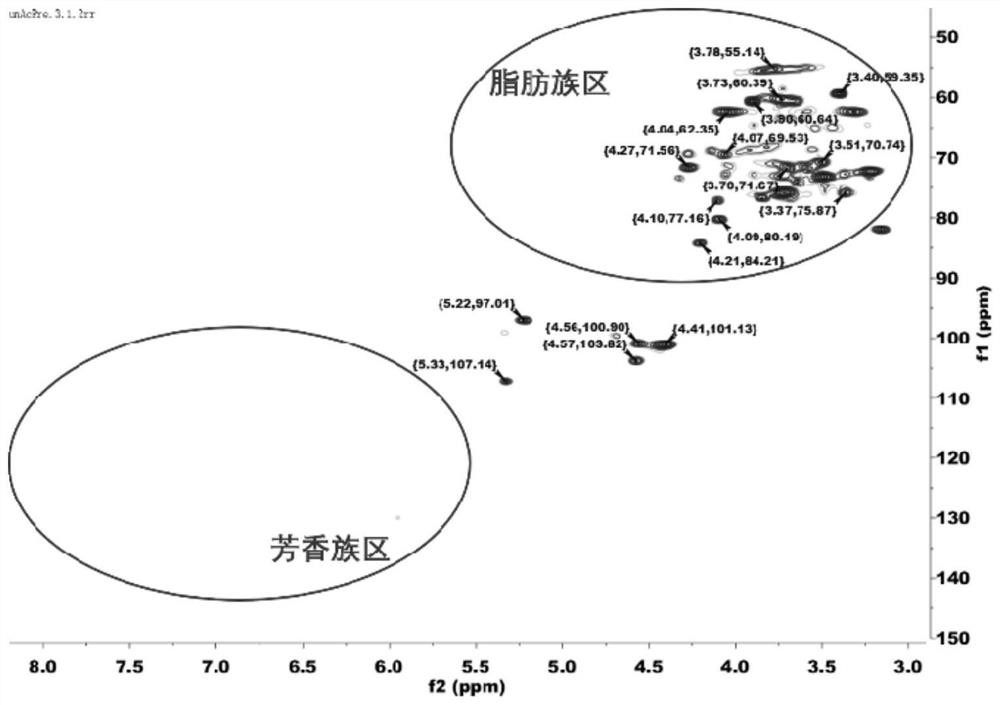

Embodiment 1

[0028] Weigh 1 kg (dry weight) of fiber plant raw material, collect yellow liquid after cooking and pulping by solid alkali active oxygen method. Sampling was performed to determine that the dry weight of the yellow liquid accounted for about 6.15% of the total liquid weight. Add the yellow liquid into a methanol solvent with a volume ratio of 5 times, and after mixing evenly, a white precipitate is precipitated. The white precipitate is a large-molecular aliphatic organic matter and a small-molecule organic acid salt. Filter and wash with methanol, dry, and weigh its weight to account for the liquid. 81.3% of the total dry weight. The mixed liquid is rectified, the solvent methanol is recovered from the top of the tower, the methanol can be reused, and the residual aqueous solution is collected in the tower kettle. Add hydrochloric acid solution to the kettle liquid to adjust the pH to 1.02, and precipitate a light yellow precipitate, which is a macromolecular aromatic organ...

Embodiment 2

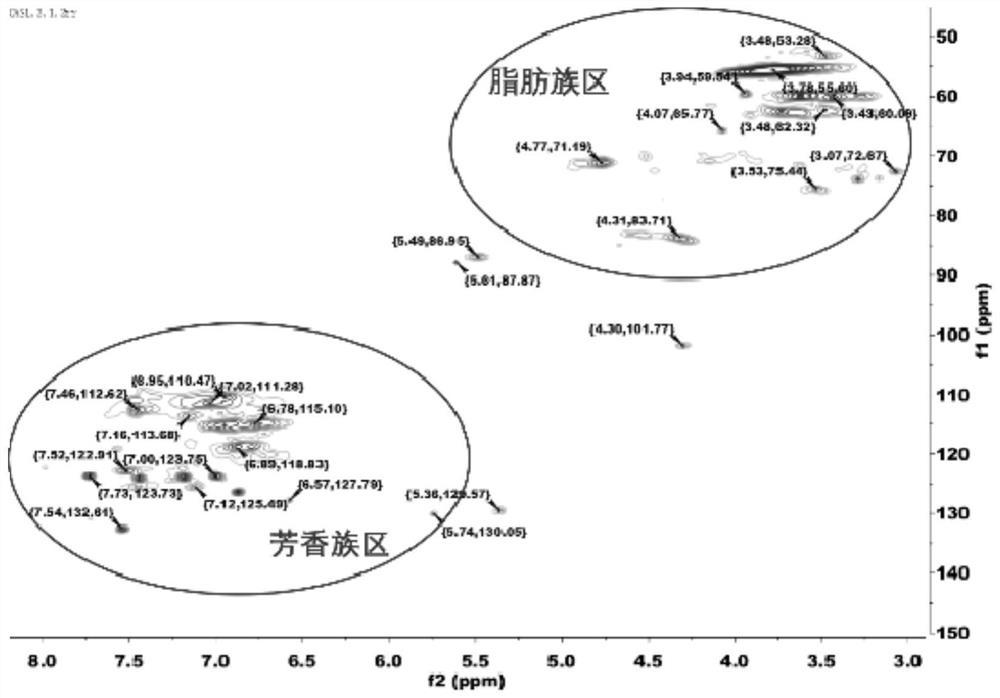

[0030] Weigh 1 kg (dry weight) of fiber plant raw material, collect yellow liquid after cooking and pulping by solid alkali active oxygen method. Sampling was performed to determine that the dry weight of the yellow liquid accounted for about 6.15% of the total liquid weight. Add the yellow liquid into a tetrahydrofuran solvent with a volume ratio of 8 times. After mixing evenly, a white precipitate is precipitated. The white precipitate is a large-molecular aliphatic organic matter and a small-molecule organic acid salt. Filter and wash with tetrahydrofuran, dry, and weigh its weight in the liquid. 81.4% of the total dry weight. The mixed liquid is rectified, the solvent tetrahydrofuran is recovered from the top of the tower, and the tetrahydrofuran can be reused, and the residual aqueous solution is collected in the tower kettle. Sulfuric acid solution is added to the kettle liquid to adjust the pH to 0.72, and a light yellow precipitate is precipitated. Part of the precip...

Embodiment 3

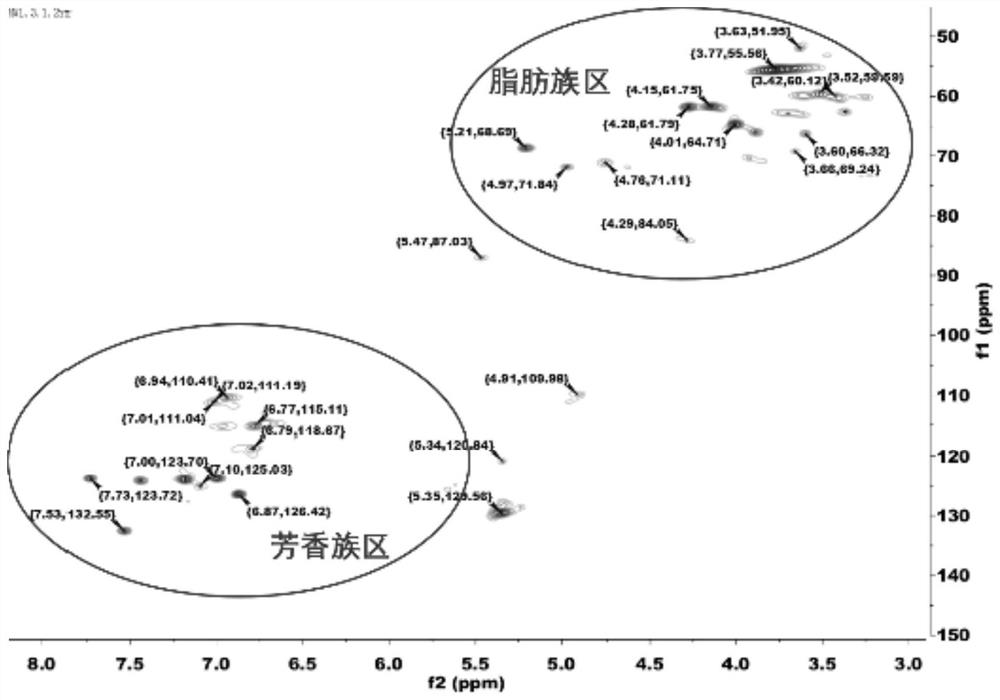

[0032] Weigh 1 kg (dry weight) of fiber plant raw material, collect yellow liquid after cooking and pulping by solid alkali active oxygen method. Sampling was performed to determine that the dry weight of the yellow liquid accounted for about 6.15% of the total liquid weight. Add the yellow liquid to the acetaldehyde solvent with a volume ratio of 2 times, and after mixing evenly, a white precipitate is precipitated. The white precipitate is a large-molecular aliphatic organic matter and a small-molecule organic acid salt. Filter and wash with acetaldehyde, dry, and weigh it. Accounting for 68.5% of the total dry weight of the liquid. The mixed liquid is rectified, the solvent acetaldehyde is recovered from the top of the tower, and the acetaldehyde can be reused, and the residual aqueous solution is collected in the bottom of the tower. Add formic acid solution to the kettle liquid to adjust the pH to 1.94, and a light yellow precipitate is precipitated. Part of the precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com