Dilute nitric acid production process

A production process, dilute nitric acid technology, applied in the chemical industry, can solve problems such as easy to burn platinum mesh, difficult overall control, product acid concentration limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

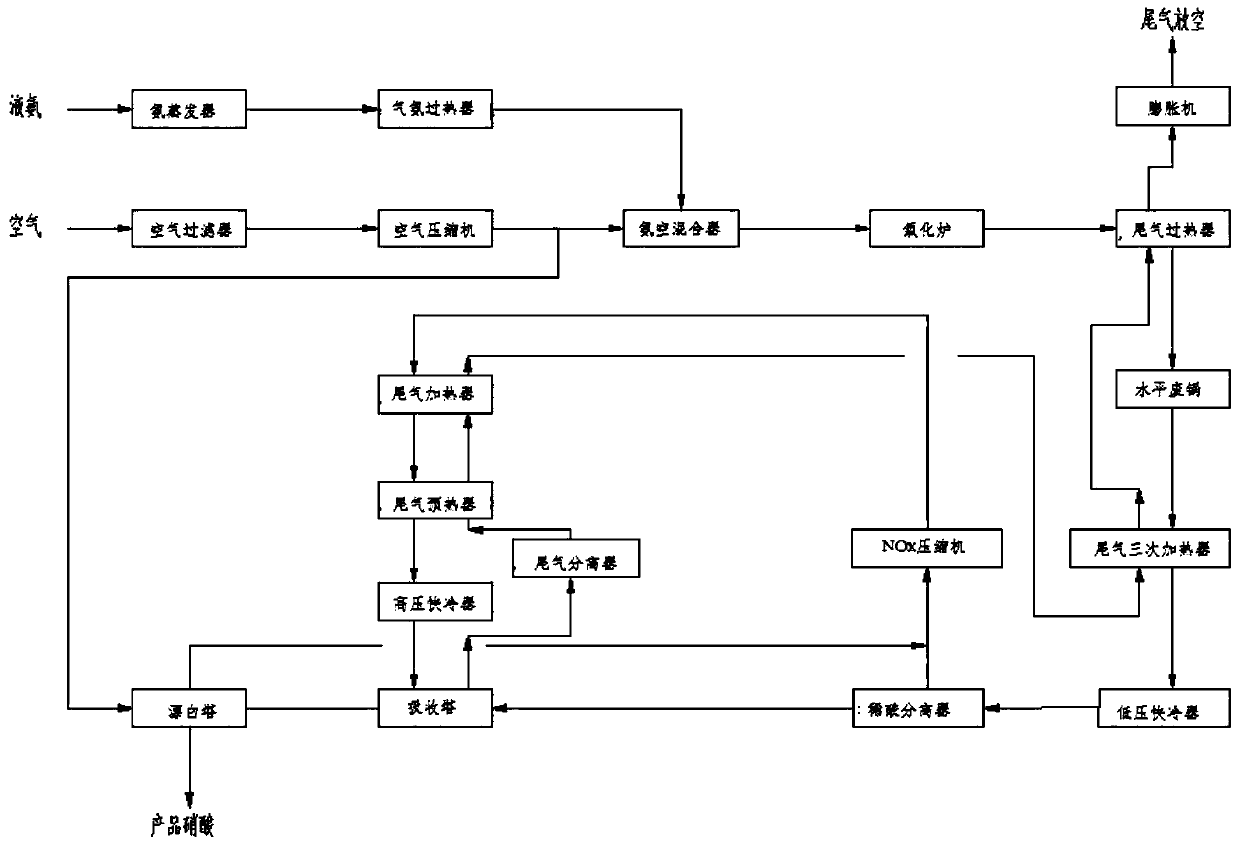

[0113] A set of 150,000 tons / year double pressurized dilute nitric acid production process:

[0114] 1: Process: The liquid ammonia from the boundary area enters the ammonia evaporator. There are two ammonia evaporators, namely ammonia evaporator A and ammonia evaporator B. Heat exchange steam, evaporated to 5.60bar abs gas ammonia. After the gas ammonia is separated from the entrained liquid droplets by the separator, it enters the gas ammonia superheater and is heated to 120°C with tail gas (steam is used when starting up). The superheated ammonia gas is sent through the ammonia filter and then sent to the ammonia-air mixer, where it is mixed with air in proportion to form an ammonia-air mixture.

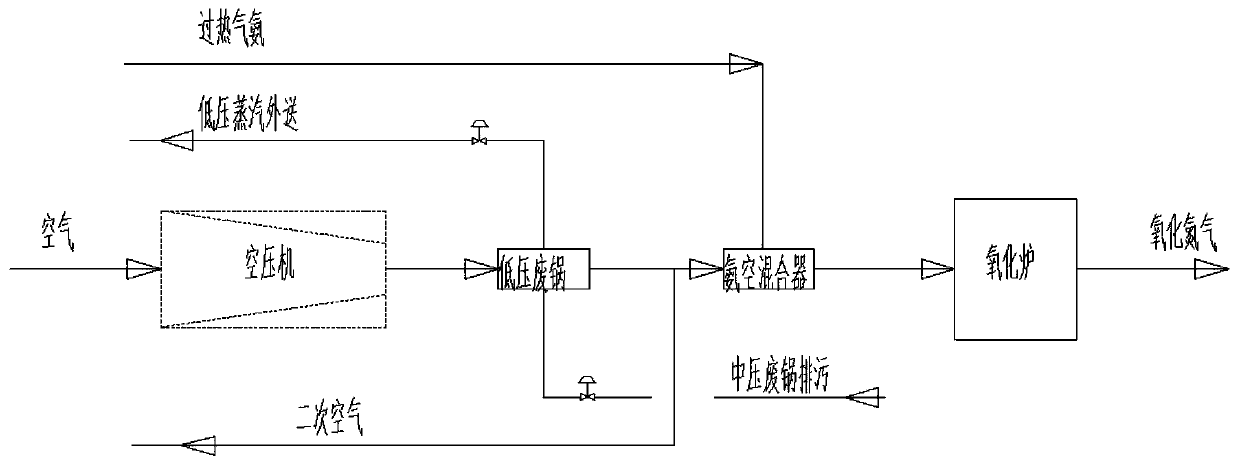

[0115] After the air passes through the filter, it enters the air compressor and is compressed to 4.2 bar abs by the air compressor. The compressed air passes through the low-pressure waste boiler, and the excess waste heat is used to generate low-pressure steam, while keeping th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com