Chain wheel outer circle and end surface grinding tool

A technology for grinding the outer circle and end face, which is applied to machine tools suitable for grinding workpiece planes, machine tools designed for grinding workpiece rotating surfaces, and grinding workpiece supports. Tolerance is difficult to guarantee and other problems, to ensure the end face runout and ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

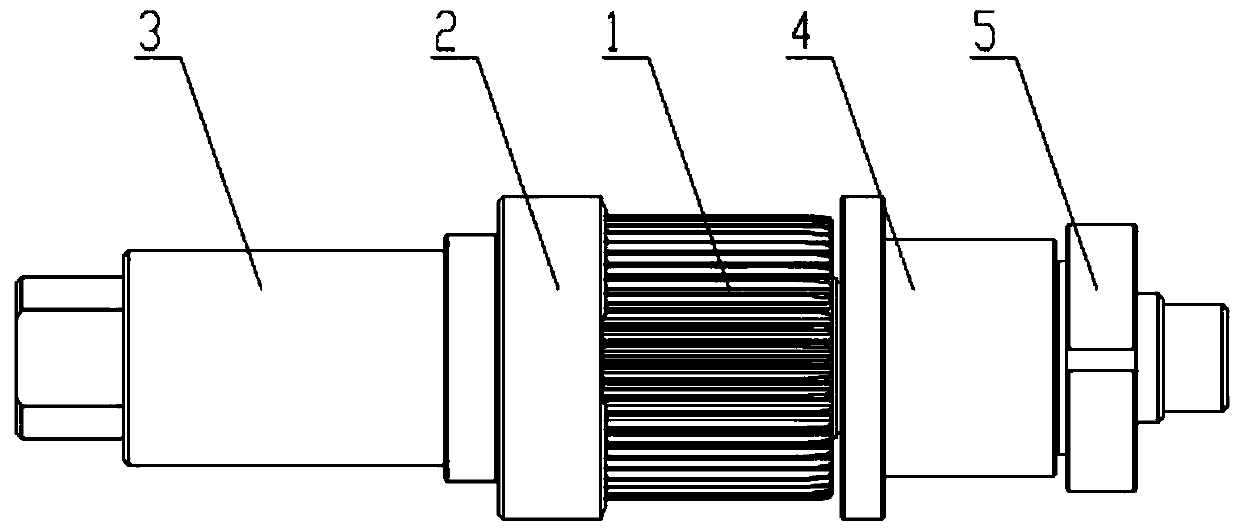

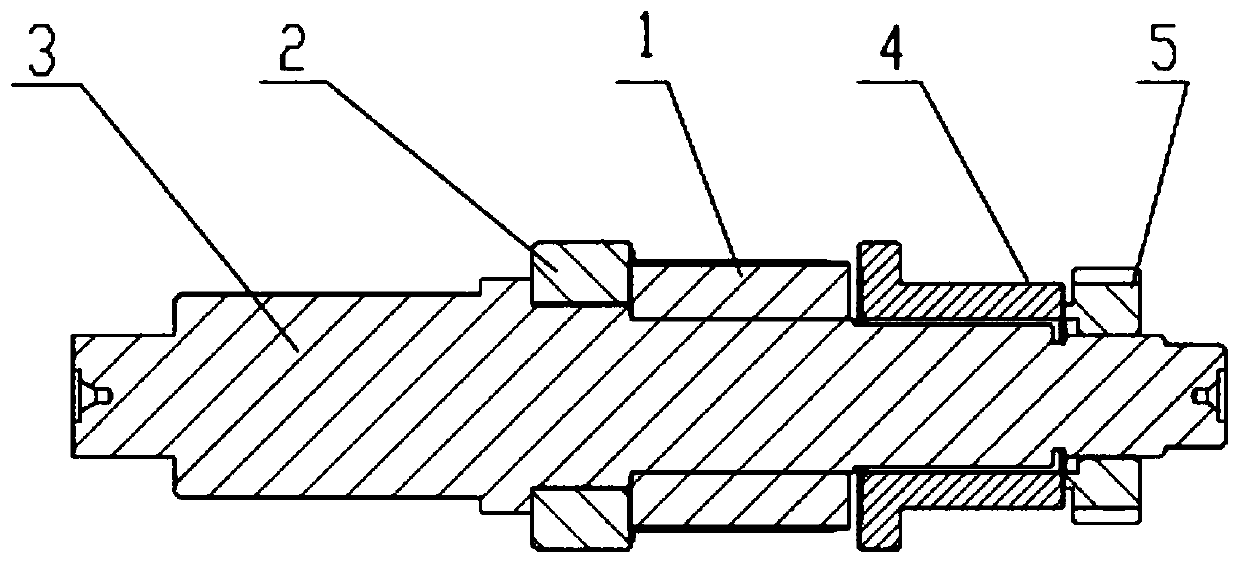

[0021] like Figure 1 ~ Figure 4 As shown, a sprocket grinding outer circle and end face tooling according to the present invention includes a mandrel 3, an end face positioning sleeve 2, a centering sleeve spline sleeve 1, a compression sleeve 4 and a flower nut 5;

[0022] Both ends of the mandrel 3 are detachably connected to the grinding machine, and the outer side of the middle end of the mandrel 3 is sleeved with an end face positioning sleeve 2, a centering sleeve spline sleeve 1, a compression sleeve 4 and a flower nut 5, The end surface positioning sleeve 2, the centering sleeve spline sleeve 1, the compression sleeve 4 and the flower nut 5 are arranged side by side in sequence along the direction of the mandrel 3 from the head end to the tail end;

[0023] The end face positioning sleeve 2 and the splined sleeve 1 of the positioning sleeve are in interference fit with the mandrel 3, the end face of the end face positioning sleeve 2 is a plane perpendicular to the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com