Anti-static thin-film switch and manufacturing method thereof

A technology of membrane switch and manufacturing method, which is applied to electrical switches, circuits, electrical components, etc., can solve problems such as difficulty in adapting to the control panel, thickening of the overall structure of the membrane switch, poor electrostatic discharge, etc., to ensure stability and good electrical conductivity. , the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

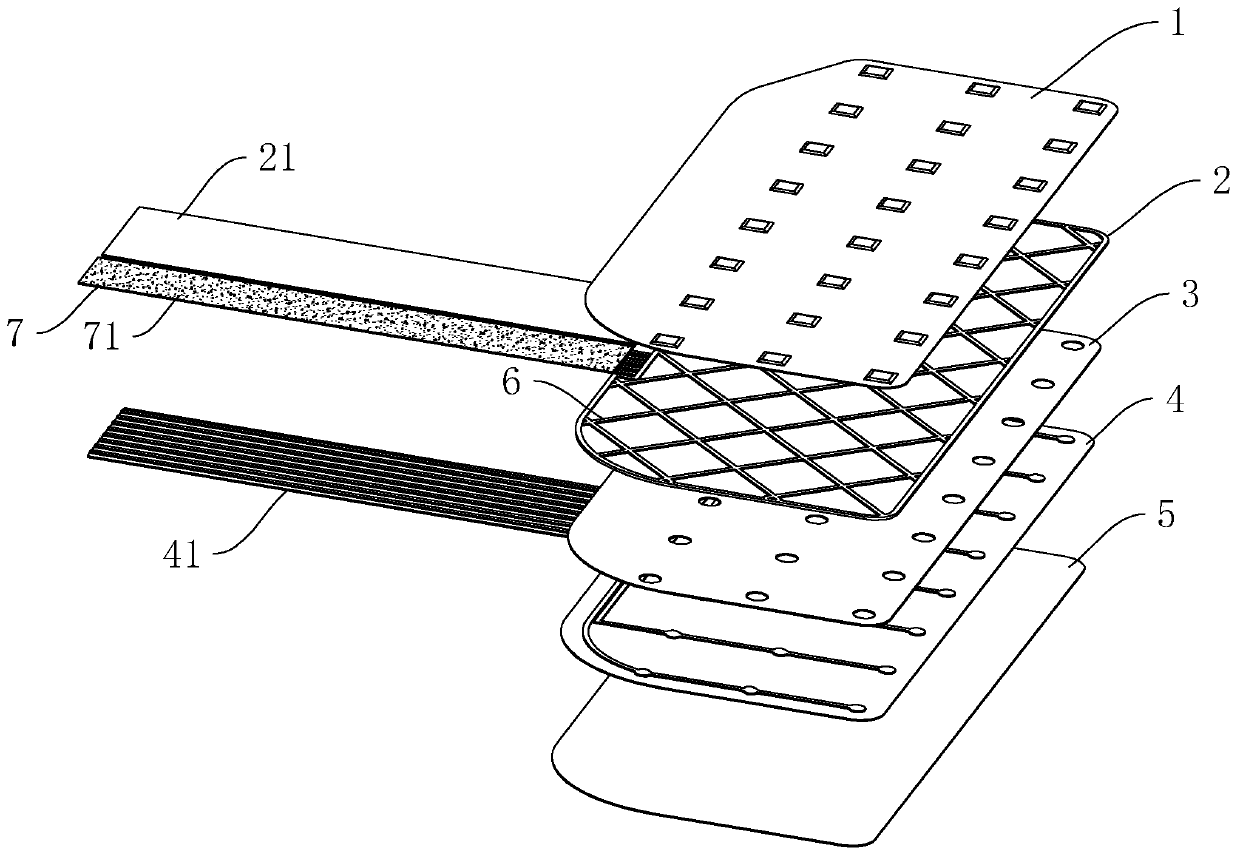

[0036] An antistatic membrane switch, such as figure 1 As shown, it includes panel 1, upper circuit layer 2, isolation layer 3, lower circuit layer 4, and primer layer 5 arranged in sequence from top to bottom. mm printing glue. Wherein, the upper surface of the upper circuit layer 2 is printed with a grid-shaped conductive silver paste layer 6, and one end of the conductive silver paste layer 6 leads to an electrostatic lead-out line 7 and is grounded. Through the conductive silver paste layer 6, the membrane switch has an antistatic Features.

[0037] Such as figure 1 As shown, the conductive silver paste layer 6 includes silver paste grid lines intersecting vertically at a pitch of 6 mm and silver paste edge lines surrounding the outside of the grid lines, and the ends of the silver paste grid lines intersect with the silver paste edge lines. Through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com