Water-based semitransparent anti-static health-care coating

An anti-static and translucent technology, applied in conductive coatings, anti-fouling/underwater coatings, and radiation-absorbing coatings, etc., it can solve the problem of reduced image clarity and brightness, easy adsorption of dust and oil, and medicines that do not reach purity, etc. To achieve the effect of improving regeneration ability, bright color and improving human microcirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

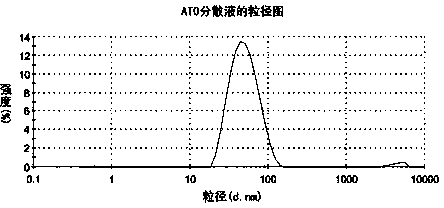

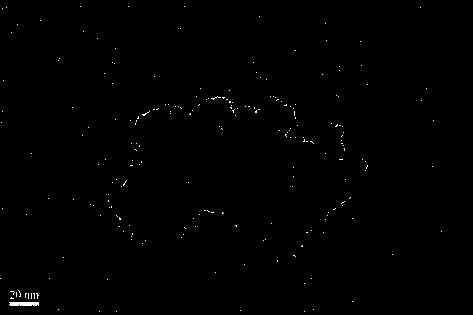

[0027] Add 1.5 g BYK-53 dispersant, 0.8 g defoamer and 1.0 g EL-2516 leveling agent into 20 g deionized water, stir at low speed for 10 minutes, add 20 g ATO aqueous dispersion (30%), 10 g negative ion powder and 5 g Iron oxide blue, mix evenly at low speed, under the action of high shear rate, stir for 10 minutes, continue to disperse to achieve a stable dispersion state, add the mixed slurry obtained above into 25 g of pure acrylic acid emulsion, stir for 10 minutes, and finally add 1.0 g of ACRYSOLTMTT -935 thickener, 1.0 g film-forming aid and 0.2 g defoamer, stirred at a low speed for 20 minutes, the water-based translucent anti-static health coating can be obtained.

Embodiment 2

[0029] Add 1.6 g BYK-53 dispersant, 0.6 g defoamer and 0.8 g EL-2516 leveling agent into 25 g deionized water, stir at low speed for 10 minutes, then add 20 g ATO aqueous dispersion (30%), 15 g negative ion powder and 8 g iron oxide red, mixed at a low speed evenly under the action of a high shear rate, stirred for 10 minutes, continued to disperse to achieve a stable state of dispersion, then added the mixed slurry obtained above to 35 g of elastic acrylic emulsion, stirred for 10 minutes, and finally added 1.2 gACRYSOLTMTT-935 thickener, 1.2 g coalescent and 0.4 g defoamer, and stirred at a low speed for 10 minutes, the water-based translucent antistatic health coating can be obtained.

Embodiment 3

[0031] Add 2 g BYK-53 dispersant, 0.5 g defoamer and 0.9 g EL-2516 leveling agent into 20 g deionized water, stir at low speed for 10 minutes, add 25 g ATO aqueous dispersion, 5 g negative ion aqueous dispersion and 10 g oxidation Iron yellow, mix evenly at a low speed, stir for 10 minutes under high shear rate, continue to disperse to achieve a stable dispersion state, add the mixed slurry obtained above to 25 g of water-based acrylic emulsion, stir for 10 minutes, mix evenly, and finally add 1.0 g of ACRYSOLTMTT-935 thickener, 1.3 g of coalescent and 0.5 g of defoamer were stirred at a low speed for 15 minutes to obtain a water-based translucent antistatic health care coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com