Pre-test treatment method of high-purity indium sample for glow discharge mass spectrometric detection

A technology of glow discharge mass spectrometry and processing method, applied in the field of high-purity metal composition analysis, can solve problems such as result deviation and impurity dissolution, and achieve the effects of improving accuracy, no impurity introduction, and relaxing the requirements of shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

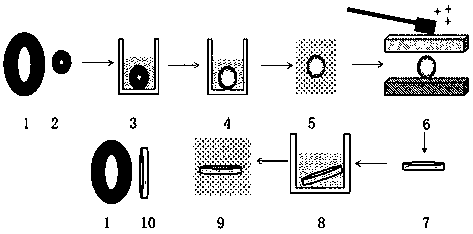

[0029] Embodiment 1: as figure 1 As shown, the pre-measurement method for the high-purity indium sample used for glow discharge mass spectrometry detection, the specific steps are as follows:

[0030] (1) Put 12g of high-purity indium sample 2 whose size is smaller than the sputtering hole 1 and does not meet the test requirements, and place it in a hydrochloric acid solution with a concentration of 6mol / L for ultrasonic corrosion for 15s (attached figure 1 as shown in 3);

[0031] (2) Place the ultrasonically etched sample in step (1) in deionized water for 360s ultrasonic cleaning (attached figure 1 4 in), and the samples after ultrasonic cleaning were blown dry with high-purity nitrogen (attached figure 1 shown in 5);

[0032] (3) Place the dried sample in step (2) between two clean and dust-free acrylic plates, and place the bottom acrylic plate on a horizontal plane;

[0033] (4) Use a clean hammer to hammer the upper acrylic plate from top to bottom above the acrylic...

Embodiment 2

[0035] Embodiment 2: The pre-measurement method of the high-purity indium sample used for glow discharge mass spectrometry detection, the specific steps are as follows:

[0036] (1) Put 7g of the high-purity indium sample 2 to be tested, which is smaller than the sputtering hole 1 and does not meet the test requirements, in a hydrochloric acid solution with a concentration of 3mol / L and ultrasonically corrode it for 85s;

[0037] (2) Place the sample after ultrasonic etching in step (1) into deionized water for ultrasonic cleaning for 170s, and dry the sample after ultrasonic cleaning with high-purity argon;

[0038] (3) Place the dried sample in step (2) between two clean and dust-free polytetrafluoroethylene plates, and place the bottom polytetrafluoroethylene plate on a horizontal plane;

[0039] (4) Use a clean hammer to hammer the upper PTFE plate from top to bottom above the upper PTFE plate of the sample. After the sample is squeezed, a plane will be formed at the botto...

Embodiment 3

[0041] Example 3: (1) Put 5 g of the high-purity indium sample 2 to be tested, which is smaller than the sputtering hole 1 and does not meet the test requirements, in a hydrochloric acid solution with a concentration of 1 mol / L for ultrasonic corrosion for 180 s;

[0042] (2) Place the sample after ultrasonic etching in step (1) into deionized water for ultrasonic cleaning for 30s, and dry the sample after ultrasonic cleaning with high-purity argon and nitrogen;

[0043] (3) Place the dried sample in step (2) between two clean and dust-free non-metal hard plates, the upper non-metal hard plate is an acrylic plate, and the bottom non-metal hard plate is a tempered glass plate , and place the tempered glass plate at the bottom on a horizontal plane;

[0044] (4) Use a clean small hammer to hammer the upper acrylic plate from top to bottom above the upper acrylic plate of the sample. After the sample is squeezed, a plane will be formed at the bottom of the sample. Continue hammerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com