A comprehensive in-furnace denitrification method for waste incineration with high efficiency and low cost

A waste incineration, low-cost technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of high cost, high catalytic denitration efficiency, low removal efficiency, etc., and achieve low cost, good effect, and improved mixing degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 A high-efficiency and low-cost integrated furnace denitrification method for waste incineration

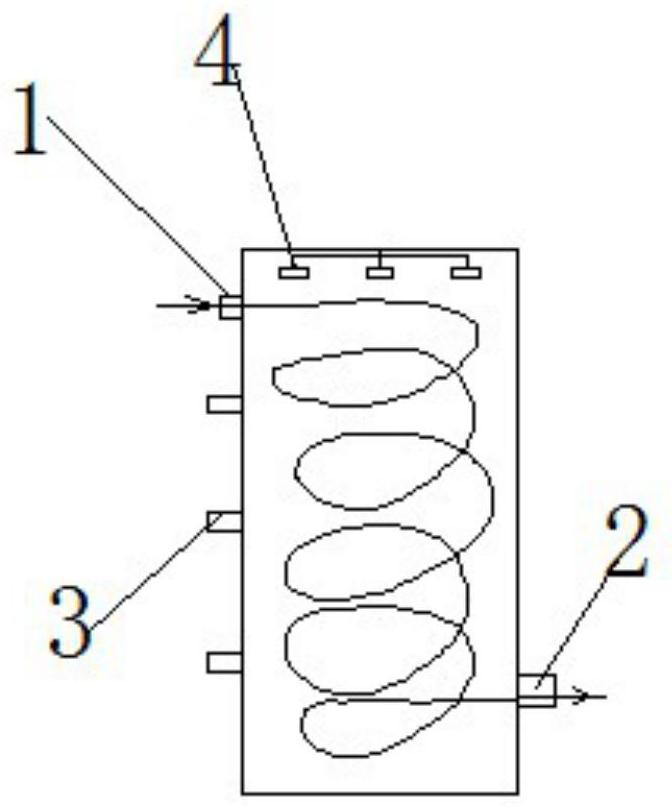

[0029] combine figure 1 It can be seen that the high-efficiency and low-cost integrated furnace denitrification method for waste incineration of the present invention, the specific steps are as follows: perform a low-nitrogen combustion step in the secondary combustion chamber, and simultaneously perform denitrification treatment in combination with urea atomization, and the treated flue gas is discharged from the secondary combustion chamber. Room for subsequent processing;

[0030] Specifically, the flue gas enters the secondary combustion chamber from the flue gas inlet 1, and the low-nitrogen combustion is mainly in the casing of the secondary combustion chamber. The flue gas inlet and outlet of the combustion chamber are set tangentially, and the temperature of the second combustion chamber is controlled at 850-950°C.

[0031] The low-nitrogen combustion in...

Embodiment 2 2

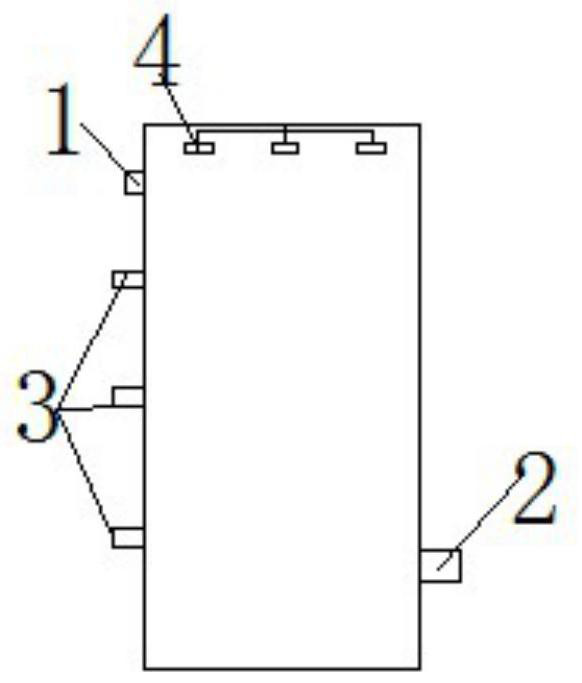

[0033] Embodiment 2 Second combustion chamber structure

[0034] The air supply port 3 is arranged on the second combustion chamber, and the air supply port 3 is located at 1 / 4, 2 / 4, and 3 / 4 of the height direction of the second combustion chamber from bottom to top; the entrance of the air supply port 3 is connected with the smoke in the second combustion chamber. The air running direction is opposite; the air volume regulating valve is set on the air supply port.

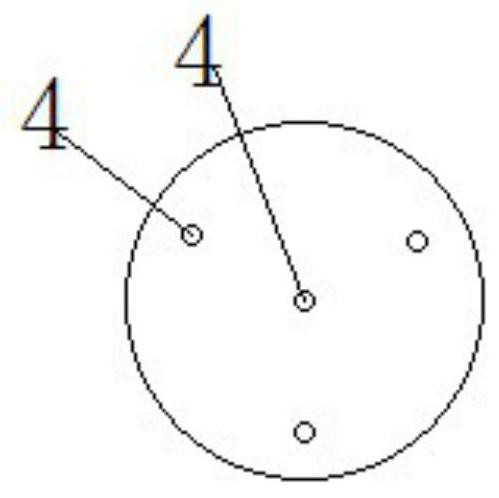

[0035] The secondary combustion chamber is a cylindrical structure with a height-to-diameter ratio of 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com