New carbonization furnace for biochar production

A biochar and carbonization furnace technology, which is applied in the field of new carbonization furnaces for biochar production, can solve the problems of limited production capacity of carbonization furnaces, the height of the furnace body should not be too high, and the volume of the furnace body should not be too large, so as to improve the production capacity of carbonization , Increase the oxygen supply and avoid the effect of polluting the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

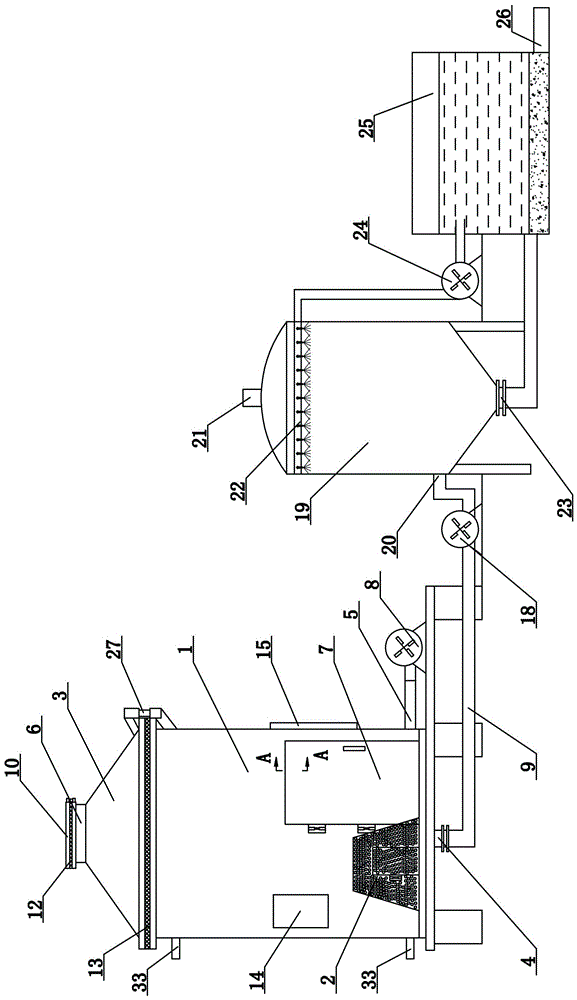

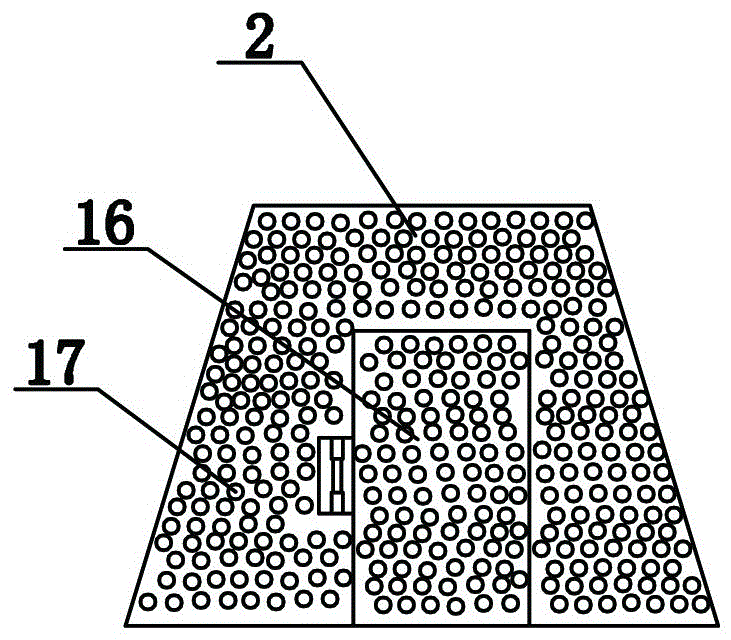

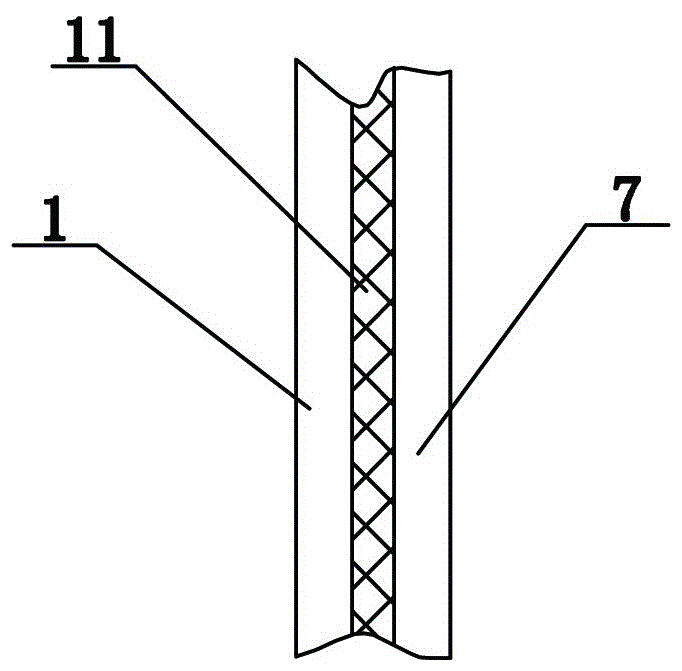

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a new type of carbonization furnace for biochar production includes furnace body 1, burner 2, furnace cover 3, smoke outlet 4, air inlet 5, charging port 6, furnace door 7, blower 8 and flue gas treatment The burner 2 is arranged in the furnace body 1. The burner 2 has a hollow cone structure, the upper end of the burner 2 is sealed, the lower end of the burner 2 is open, and the lower part of the burner 2 is provided with a cleaning door 16 and a cleaning door 16 It is movably connected with the lower part of the burner 2 through a hinge, and the burner 2 is densely arranged with combustion holes 17. A furnace cover 3 is arranged on the upper part of the furnace body 1, and the furnace cover 3 and the upper end of the furnace body 1 are movably connected by hinges 27 and fastened by bolts. A m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com