High-stretchability and self-repairing hydrogel and preparation method thereof

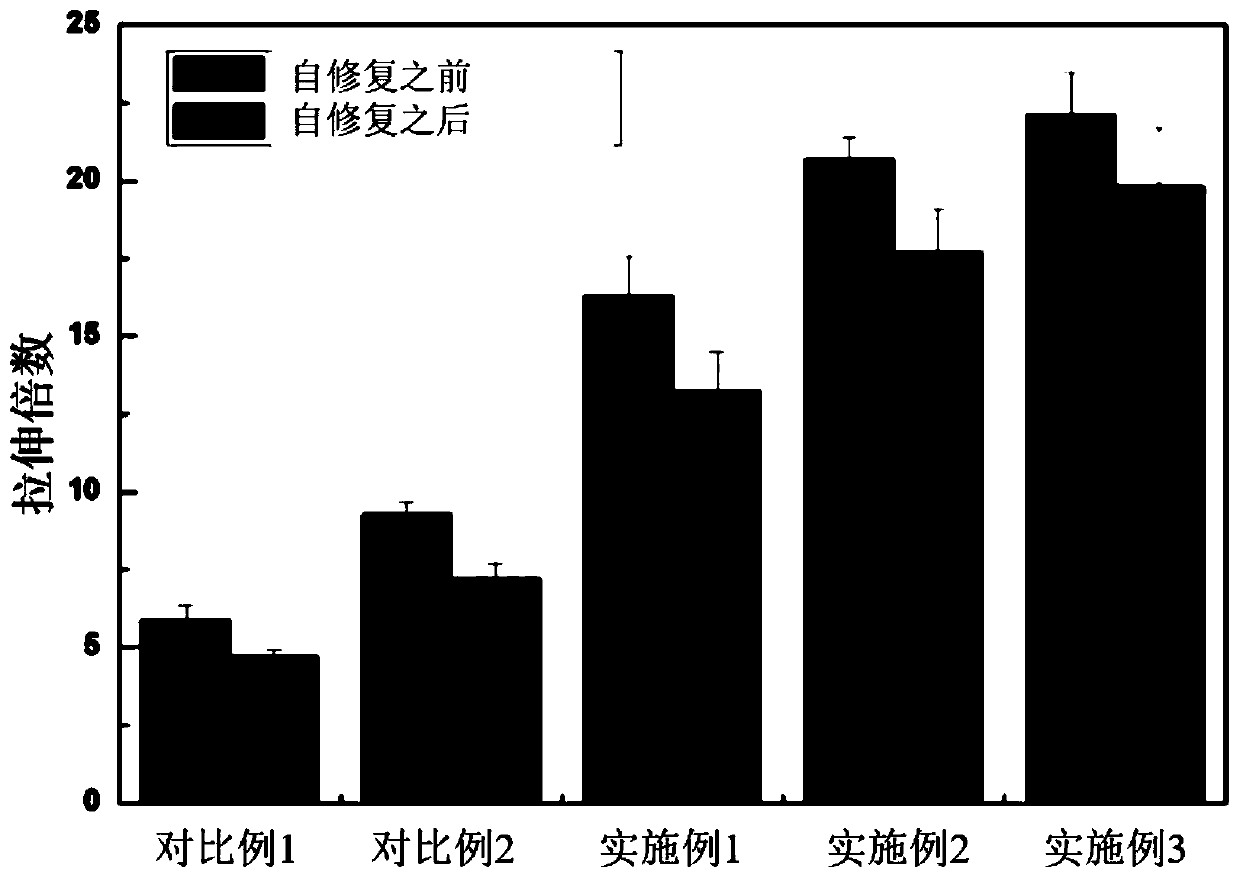

A technology of hydrogel and stretchability, which is applied in the field of new polymer functional materials, can solve the problems of low stretching ratio of hydrogel, complex self-repair conditions, long self-repair time, etc., and achieve fast preparation speed and molding speed Fast and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

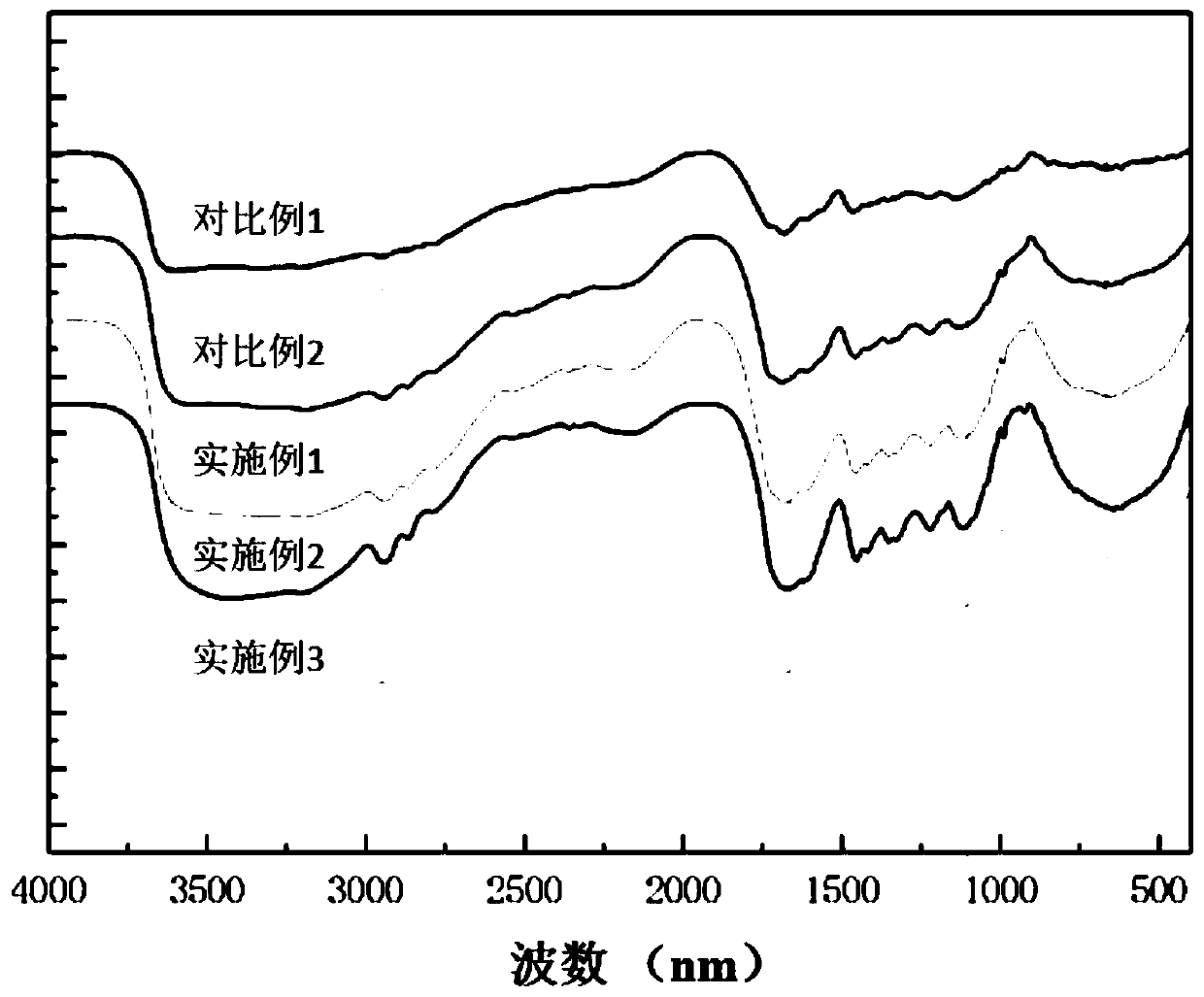

Embodiment 1

[0037] Prepare the hydrogel as follows:

[0038] S1. Weigh 4.5 parts of monomer acrylamide, 1.5 parts of dimethylaminoethyl methacrylate, 0.01 part of aqueous crosslinking agent, 0.005 part of initiator, 20 to 30 parts of deionized water, preferably 24 parts; The agent ammonium persulfate, deionized water, monomer acrylamide, dimethylaminoethyl methacrylate and water-soluble crosslinking agent water-soluble hexamethylene diisocyanate trimer were added to the reaction vessel and mixed well;

[0039] S2. Ultrasonic treatment of the mixture in step S1 for 30-120s; preferably ultrasonic treatment for 60s

[0040] S3. The mixture in step S2 is allowed to stand at 80-90°C for 1-35 minutes, usually for 5 minutes, to form a hydrogel, and after cooling to 15-30°C, take out.

[0041] Wherein the preparation method of water-soluble crosslinking agent water-soluble hexamethylene diisocyanate trimer is as follows: weigh 6g of monohydroxy polyether (molecular weight 550) in a single-necked...

Embodiment 2

[0043] Prepare the hydrogel as follows:

[0044] S1. Weigh 4.8 parts of monomer acrylamide, 1.2 parts of dimethylaminoethyl methacrylate, 0.01 part of aqueous crosslinking agent, 0.005 part of initiator, 20 to 30 parts of deionized water, preferably 24 parts; The agent ammonium persulfate, deionized water, monomer acrylamide, dimethylaminoethyl methacrylate and water-soluble crosslinking agent water-soluble hexamethylene diisocyanate trimer were added to the reaction vessel and mixed well;

[0045] S2. Ultrasonic treatment of the mixture in step S1 for 30-120s; preferably ultrasonic treatment for 60s

[0046] S3. The mixture in step S2 is allowed to stand at 80-90°C for 1-35 minutes, usually for 5 minutes, to form a hydrogel, and after cooling to 15-30°C, take out.

[0047] Wherein the preparation method of water-soluble crosslinking agent water-soluble hexamethylene diisocyanate trimer is as follows: weigh 6g of monohydroxy polyether (molecular weight 550) in a single-necked...

Embodiment 3

[0049] Prepare the hydrogel as follows:

[0050]S1. Weigh 5 parts of monomer acrylamide, 1 part of dimethylaminoethyl methacrylate, 0.01 part of aqueous crosslinking agent, 0.005 part of initiator, 20 to 30 parts of deionized water, preferably 24 parts; The agent ammonium persulfate, deionized water, monomer acrylamide, dimethylaminoethyl methacrylate and water-soluble crosslinking agent water-soluble hexamethylene diisocyanate trimer were added to the reaction vessel and mixed well;

[0051] S2. Ultrasonic treatment of the mixture in step S1 for 30-120s; preferably ultrasonic treatment for 60s

[0052] S3. The mixture in step S2 is allowed to stand at 80-90°C for 1-35 minutes, usually for 5 minutes, to form a hydrogel, and after cooling to 15-30°C, take out.

[0053] Wherein the preparation method of the water-soluble crosslinking agent water-soluble hexamethylene diisocyanate trimer is as follows: weigh 6 g of monohydroxy polyether (molecular weight 550) in a single-necked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com