Water-based fluorinated acrylate copolymer and hybrid membrane, and preparation methods and application thereof

An acrylate and alkyl acrylate technology, which is applied to water-based fluorine-containing acrylate copolymers, hybrid films and their preparation and application fields, can solve the problems of single structure, unfriendly environment, toxicity and the like of fluorine-containing polyacrylates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

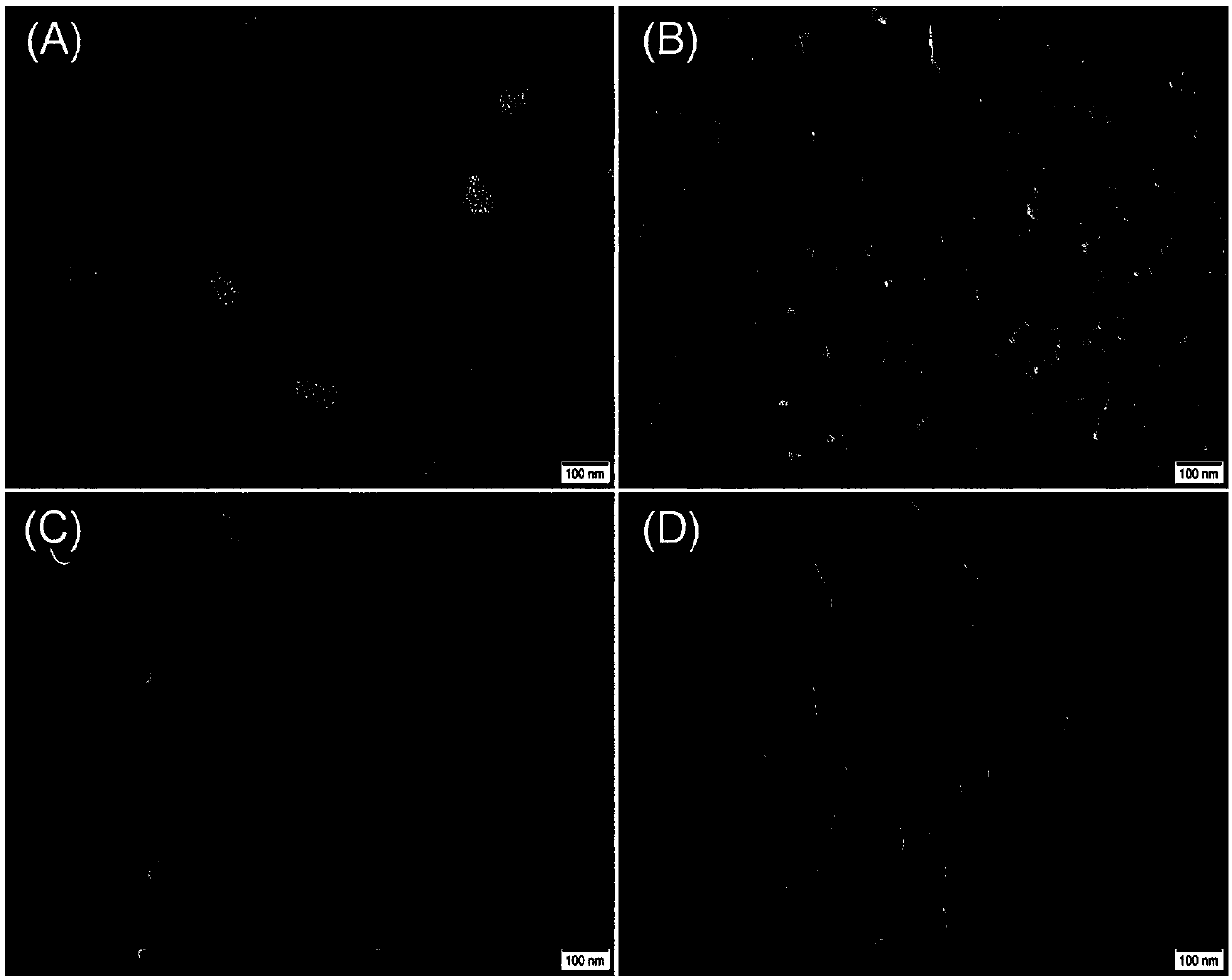

Image

Examples

Embodiment 1

[0088] Example 1 Preparation of 2-(perfluoro 1,1-dimethyl-butyl) ethyl acrylate

[0089]

[0090] Synthesis and characterization of compound 2

[0091] KF (7.08g, 0.12mol, 1.2equiv.), compound 1 (30.00g, 0.10mol, 1.0equiv.), ethyl bromoacetate (18.37g, 0.11mol, 1.1equiv.), four Butylammonium bromide (0.50g, 1.5mmol, 0.015equiv.) and 100mL of anhydrous DMF were sealed and placed in an oil bath at 80°C for 24h with stirring. After cooling to room temperature, the reaction system was poured into diethyl ether, and the diethyl ether solution was washed with deionized water and saturated brine successively, dried over anhydrous sodium sulfate, filtered, concentrated, and separated and purified by column chromatography (EtOAc:petroleum=1:20). 31.6 g of a colorless liquid product was obtained with a yield of 78%. LCMS (EI) m / z (%): 361.1 (100), 406.1 (2.1).

[0092] 1 H NMR (300MHz, CDCl3) δ4.30–4.06(m, 2H), 3.12(s, 2H), 1.24(t, J=7.1Hz, 3H).

[0093] 19 F NMR (282MHz, CDCl3...

Embodiment 2

[0105] (1) Add 1.5 g of deionized water, 0.328 g of methyl methacrylate, 1.232 g of butyl methacrylate, and 0.04 g of emulsifier DNS-86 into a 10 mL reaction flask, and stir vigorously at room temperature for 0.5 hours to form a pre-emulsion Ⅰ; Add 1.5g of deionized water, 0.396g of methyl methacrylate, 0.528g of butyl methacrylate, 0.5g of octadecyl acrylate, 0.035g of hydroxyethyl acrylate, 2-(perfluoro 0.2 g of 1,1-dimethyl-butyl) ethyl acrylate and 0.04 g of emulsifier DNS-86 were stirred vigorously at room temperature for 0.5 hours to form pre-emulsion II. Add 2.7 g of deionized water and 0.04 g of ammonium persulfate in sequence to a 10 mL reaction flask, and dissolve at room temperature.

[0106] (2) Add 0.04g DNS-86 to a 20mL three-necked flask, add 1 / 3 initiator aqueous solution, 1 / 3 pre-emulsion I and 1.5mL distilled water under nitrogen protection, stir at 250rpm at 50°C for 20 minutes, the system Triggered successfully, blue phase appeared. Gradually raise the te...

Embodiment 3

[0108] (1) Add 1.5 g of deionized water, 0.328 g of methyl methacrylate, 1.232 g of butyl methacrylate, and 0.04 g of emulsifier DNS-86 into a 10 mL reaction flask, and stir vigorously at room temperature for 0.5 hours to form a pre-emulsion Ⅰ; Add 1.5g of deionized water, 0.396g of methyl methacrylate, 0.528g of butyl methacrylate, 0.5g of octadecyl acrylate, 0.035g of hydroxyethyl acrylate, 2-(perfluoro 0.4 g of 1,1-dimethyl-butyl) ethyl acrylate and 0.04 g of emulsifier DNS-86 were stirred vigorously at room temperature for 0.5 hours to form pre-emulsion II. Add 4 g of deionized water and 0.04 g of ammonium persulfate in sequence to a 10 mL reaction flask, and dissolve at room temperature.

[0109] (2) Add 0.04g DNS-86 to a 20mL three-necked flask, add 1 / 3 initiator aqueous solution, 1 / 3 pre-emulsion I and 1.5mL distilled water under nitrogen protection, stir at 250rpm at 60°C for 20 minutes, the system Triggered successfully, blue phase appears. Gradually raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com