Machining equipment for machining two sides of stone plate

A technology for processing equipment and plates, which is applied in the field of stone plate processing equipment, can solve the problems of inconvenient adjustment of the position of the grinding disc and low efficiency of grinding, and achieve the effects of improving convenience, improving efficiency, and strong implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

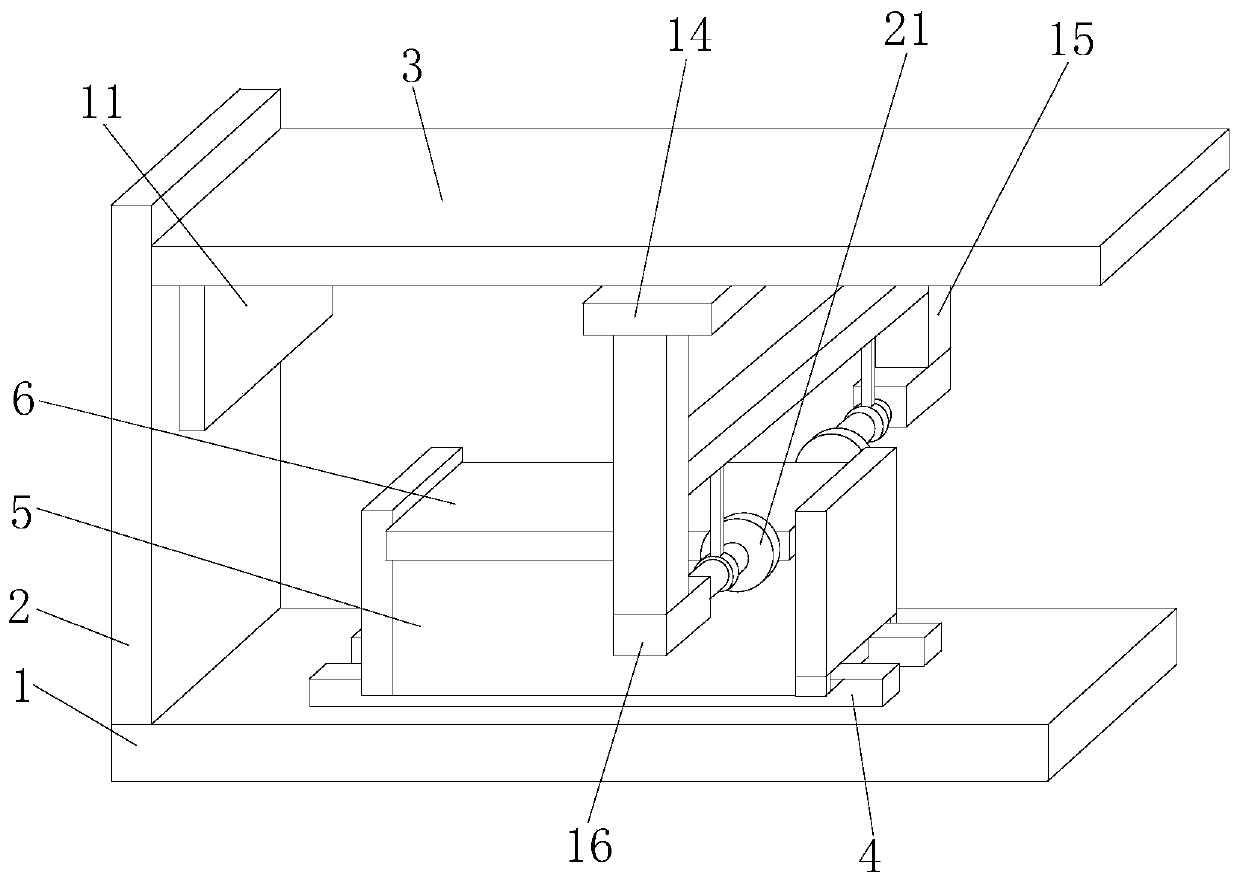

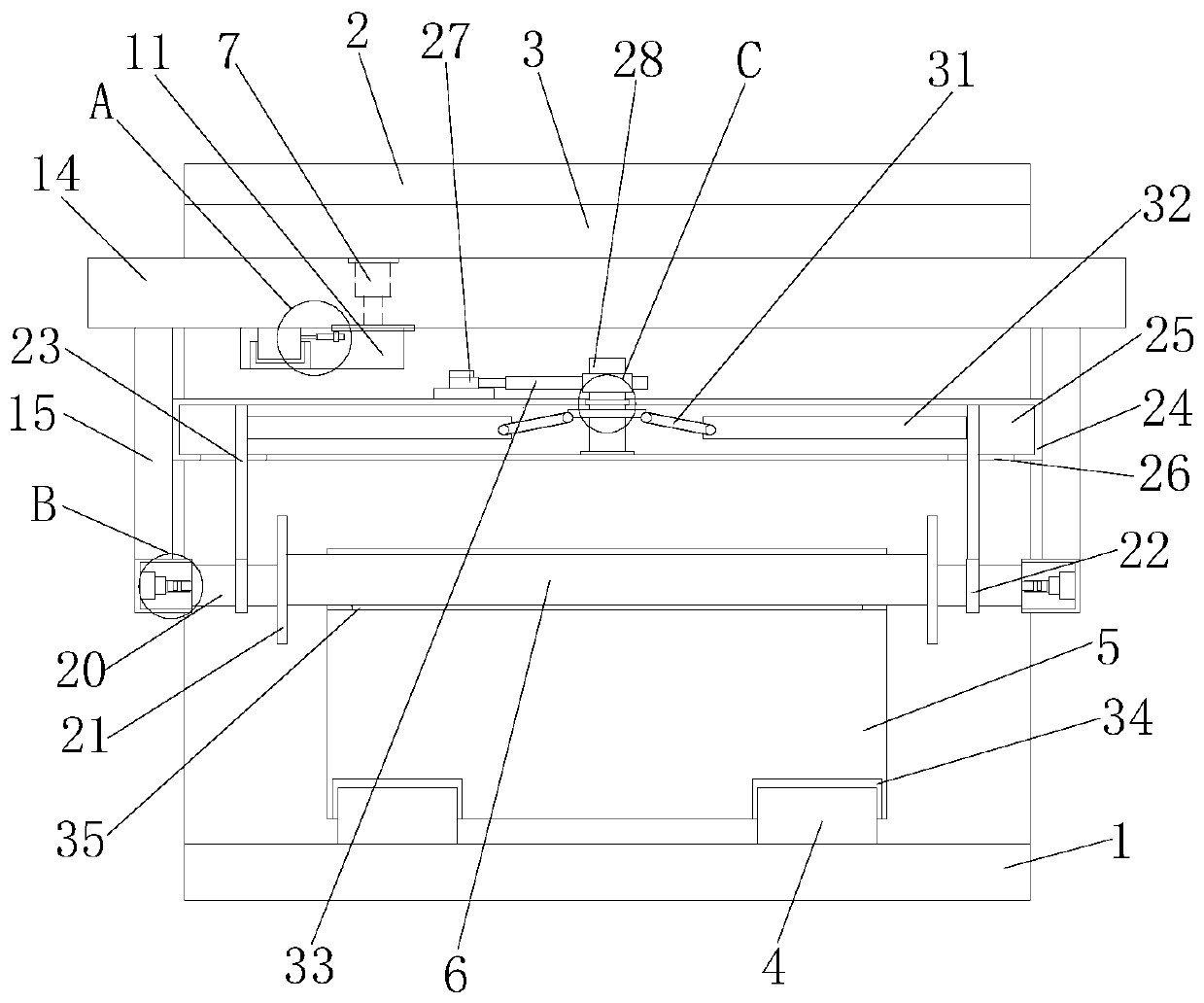

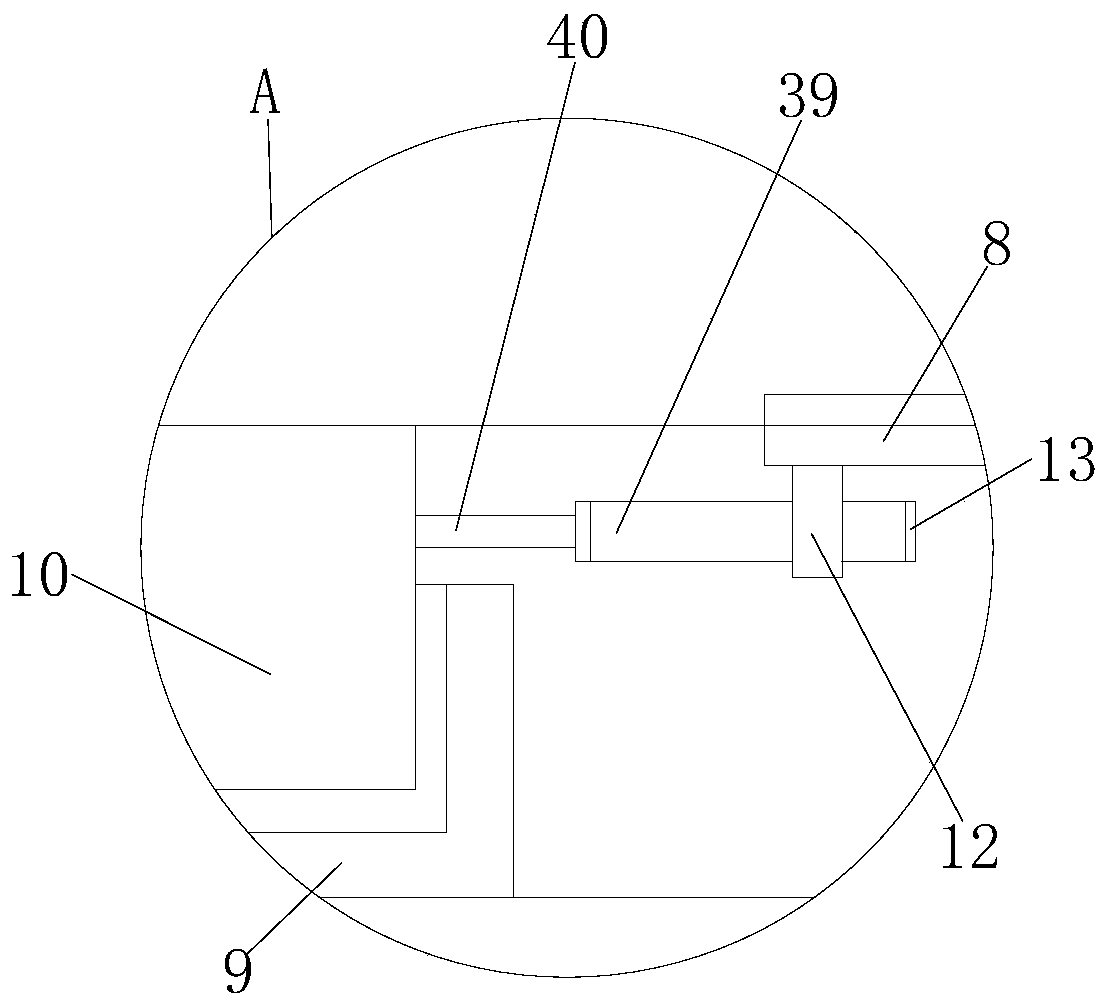

[0024] refer to Figure 1-5 In this embodiment, a processing device for processing both sides of stone slabs is proposed, including a bottom plate 1, a vertical plate 2 is fixedly installed on the top of the bottom plate 1, and a mounting plate 3 is fixedly installed on one side of the vertical plate 2, and the installation The bottom of the plate 3 is slidably mounted with a slide plate 14, the bottom of the mounting plate 3 is provided with a drive mechanism, and the drive mechanism is connected to the slide plate 14 in transmission, and the bottom of the slide plate 14 is fixedly equipped with two symmetrically arranged fixed plates 15, two fixed plates 15 The bottom of the drive block 16 is fixedly installed, and the side of the two drive blocks 16 close to each other is provided with a mounting groove 36, and a servo motor 17 is fixedly installed on the inner wall of the side of the two mounting grooves 36, and the output shaft of the servo motor 17 One end of the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com