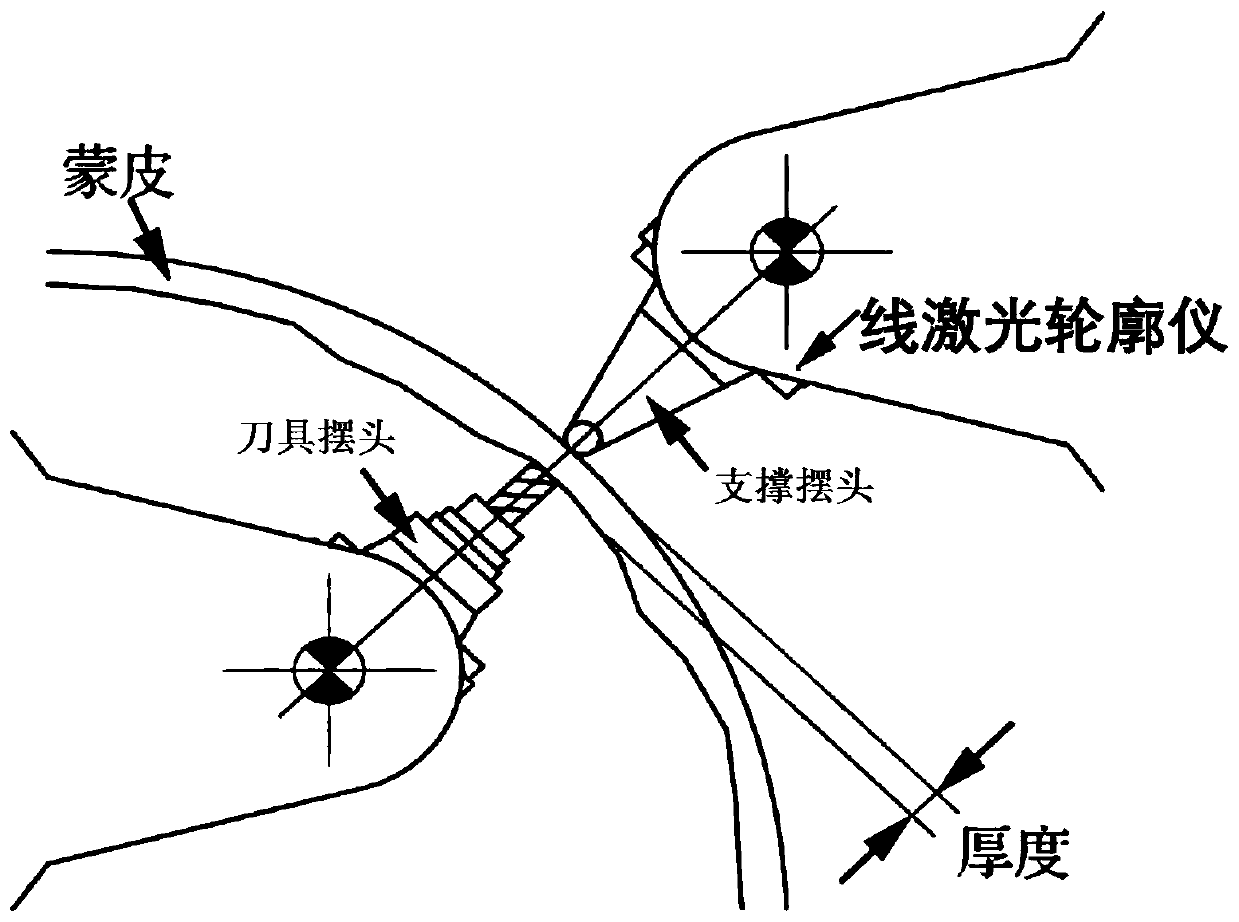

Precision self-diagnosis method of double-five-axis mirror milling machine tool

A self-diagnosis and machine tool technology, applied in milling machine equipment, milling machine equipment details, automatic control devices, etc., can solve the lack of line laser profiler on-site detection accuracy diagnostic calibration, lack of motion synchronization accuracy detection, lack of individual machine tool accuracy evaluation, etc. problems, to achieve the effect of improving diagnostic efficiency, saving installation time, and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

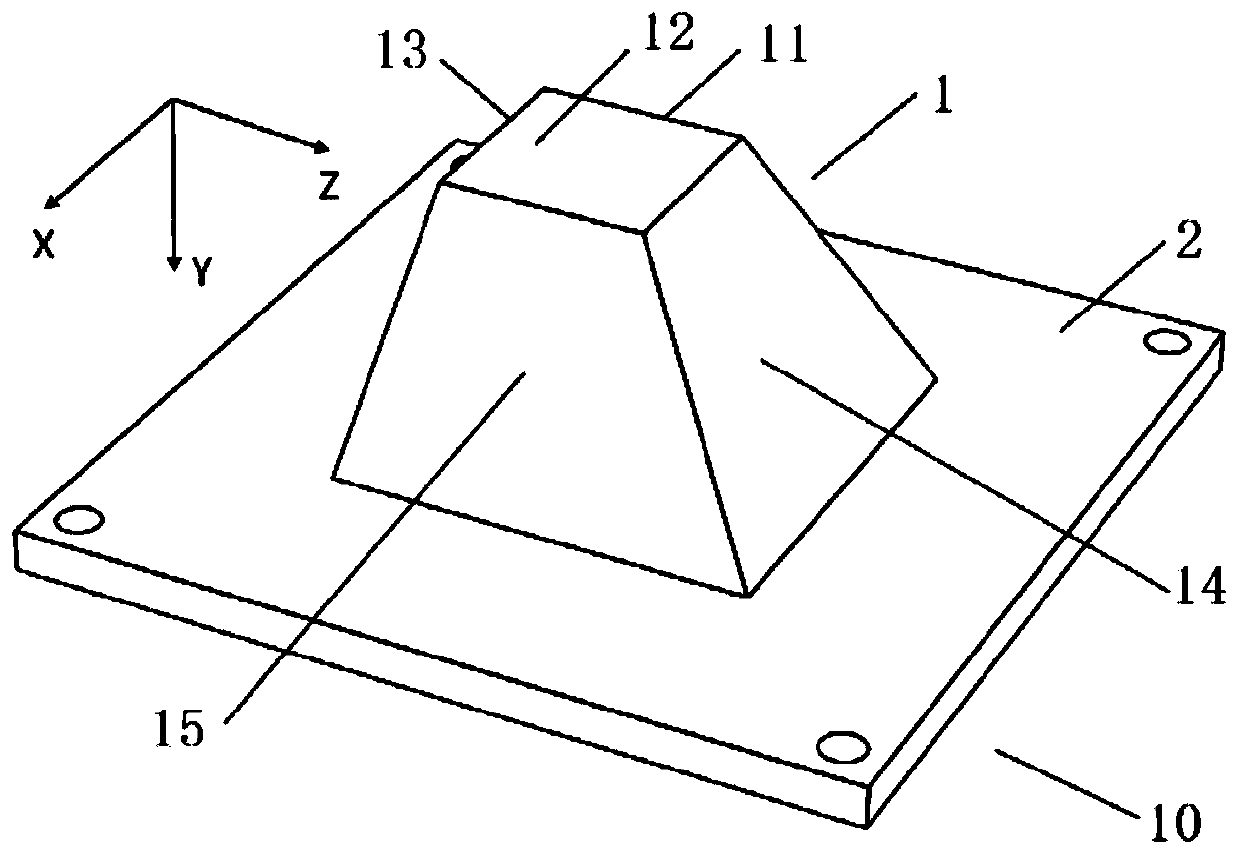

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

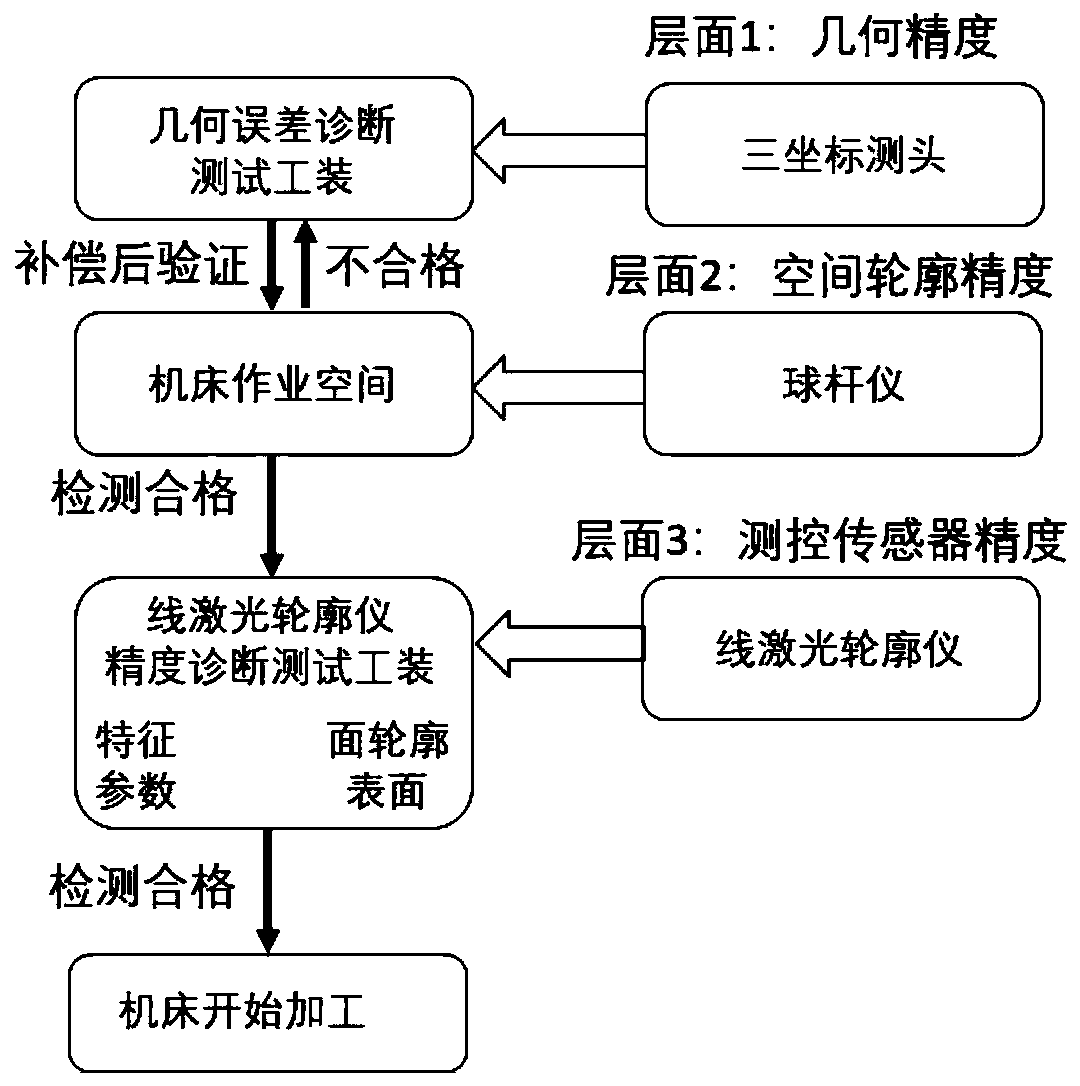

[0049] A precision self-diagnosis method for a dual-five-axis mirror milling machine tool according to an embodiment of the present invention includes self-diagnosis at two levels of geometric precision and spatial contour precision, and its working process is as follows figure 2 As shown, it specifically includes the following steps:

[0050] 1) Judging whether the previous workpiece meets the set processing accuracy requirements, if not, then perform step 2), and perform geometric accuracy self-diagnosis on the dual five-axis mirror milling machine; Self-diagnosis of the spatial contour accuracy of the machine tool operation by the axis mirror milling machine tool;

[0051] 2) Self-diagnosis of geometric accuracy of dual five-axis mirror milling machine tools

[0052] Based on the geometric accuracy mathematical model of the dual-five-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com