Nourishing and moisturizing lotion prepared with D-phase emulsifying method and preparation method thereof

A technology of emulsification and lotion, applied in the field of moisturizing lotion and its preparation, can solve the problems of poor stability of lotion and poor moisturizing effect, achieve excellent moisturizing effect, improve moisturizing degree, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

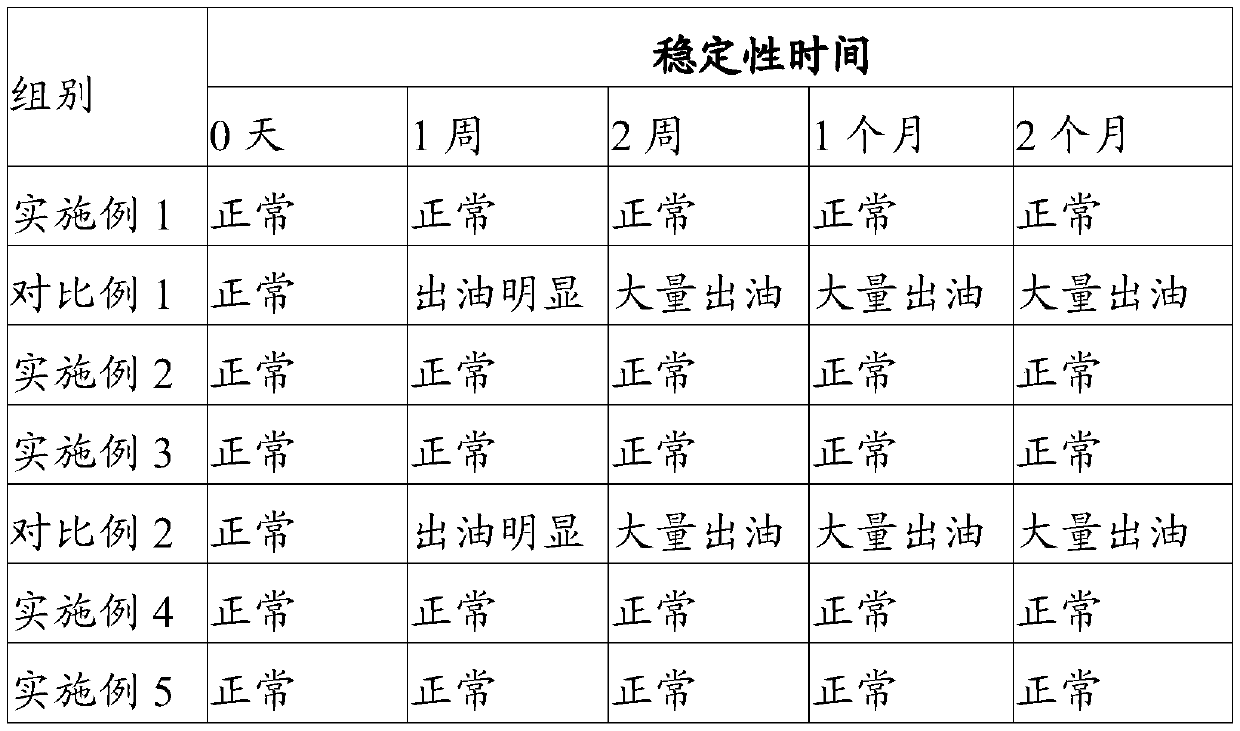

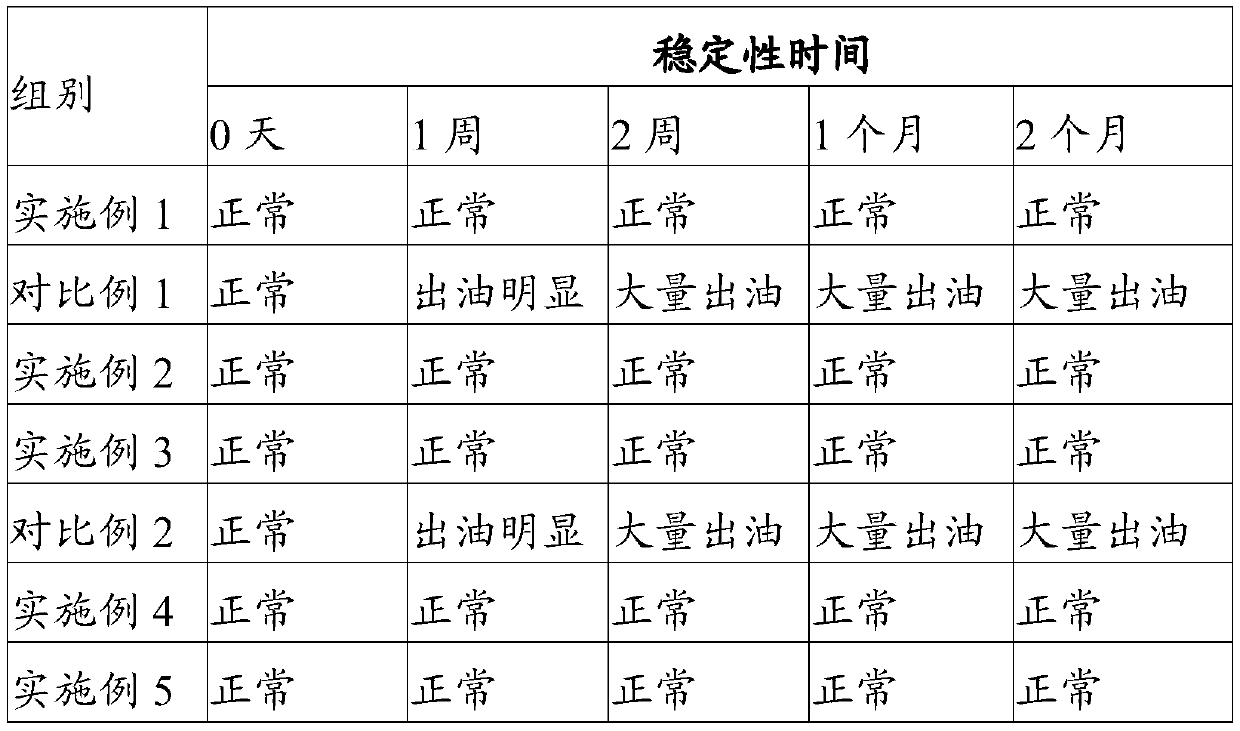

Examples

Embodiment 1

[0057] Moisturizing and moisturizing lotion prepared by D-phase emulsification method and its preparation method, calculated by weight percentage, comprising: 1.0% of sorbitan sesquioleate; 0.1% of tocopheryl acetate; 0.1% of octyl dodecyl alcohol; PEG - 40 Hydrogenated Castor Oil 0.5%; 1,3-Butanediol 9.0%; Glycerin 4.0%; Polyglycerol-10, 3.0%; 1,2-Pentanediol 1.0%; %, purslane extract 1.0%, phenoxyethanol 0.3%, the balance water. The production steps are as follows:

[0058] 1) According to the formula ratio, mix PEG-40 hydrogenated castor oil, 1,3-butanediol, glycerin, polyglycerol-10, 1,2-pentanediol, heat and stir to 78-80°C to obtain a uniformly dispersed mixed components;

[0059] 2) heating sorbitan sesquioleate, tocopheryl acetate, and octyldodecanol to 78-80°C and stirring to obtain a uniform oil phase component;

[0060] 3) Stir the mixed components obtained in step 2) at a rate of 350-400rpm, and simultaneously add the oil phase components obtained in step 2) to ...

Embodiment 2

[0064] Moisturizing and moisturizing lotion prepared by D-phase emulsification method and its preparation method, calculated by weight percentage, comprising: 1.0% of sorbitan sesquioleate; 0.1% of tocopheryl acetate; 0.5% of octyl dodecyl alcohol; PEG - 60 Hydrogenated Castor Oil 0.4%; 1,3-Butanediol 9.0%; Glycerin 5.0%; Polyglycerol-10, 3.0%; 1,2-Pentanediol 1.0%; %, purslane extract 1.0%, phenoxyethanol 0.3%, the balance water. The production steps are as follows:

[0065] 1) According to the formula ratio, mix PEG-60 hydrogenated castor oil, 1,3-butanediol, glycerin, polyglycerol-10, and 1,2-pentanediol, heat and stir to 75-78°C to obtain a uniformly dispersed mixed components;

[0066] 2) heating sorbitan sesquioleate, tocopheryl acetate, and octyldodecanol to 75-78°C and stirring to obtain a uniform oil phase component;

[0067] 3) Stir the mixed components obtained in step 2) at a rate of 350-400rpm, and simultaneously add the oil phase components obtained in step 2)...

Embodiment 3

[0071] Moisturizing and moisturizing lotion prepared by D-phase emulsification method and its preparation method, calculated by weight percentage, comprising: 1.0% of sorbitan sesquioleate; 0.1% of tocopheryl acetate; 0.1% of octyl dodecyl alcohol; PEG - 60 Hydrogenated Castor Oil 0.3%; 1,3-Butanediol 9.0%; Glycerin 3.0%; Polyglycerol-10, 2.0%; 1,2-Pentanediol 1.0%; %, purslane extract 1.0%, phenoxyethanol 0.3%, the balance water. The production steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com