Space corner smoothing method based on three-dimensional generalized Euler spiral

A Euler spiral and generalized technology, which is applied in the field of space corner smoothing based on three-dimensional generalized Euler spiral, can solve problems such as inability to smooth space corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will now be further described in conjunction with the embodiments and drawings:

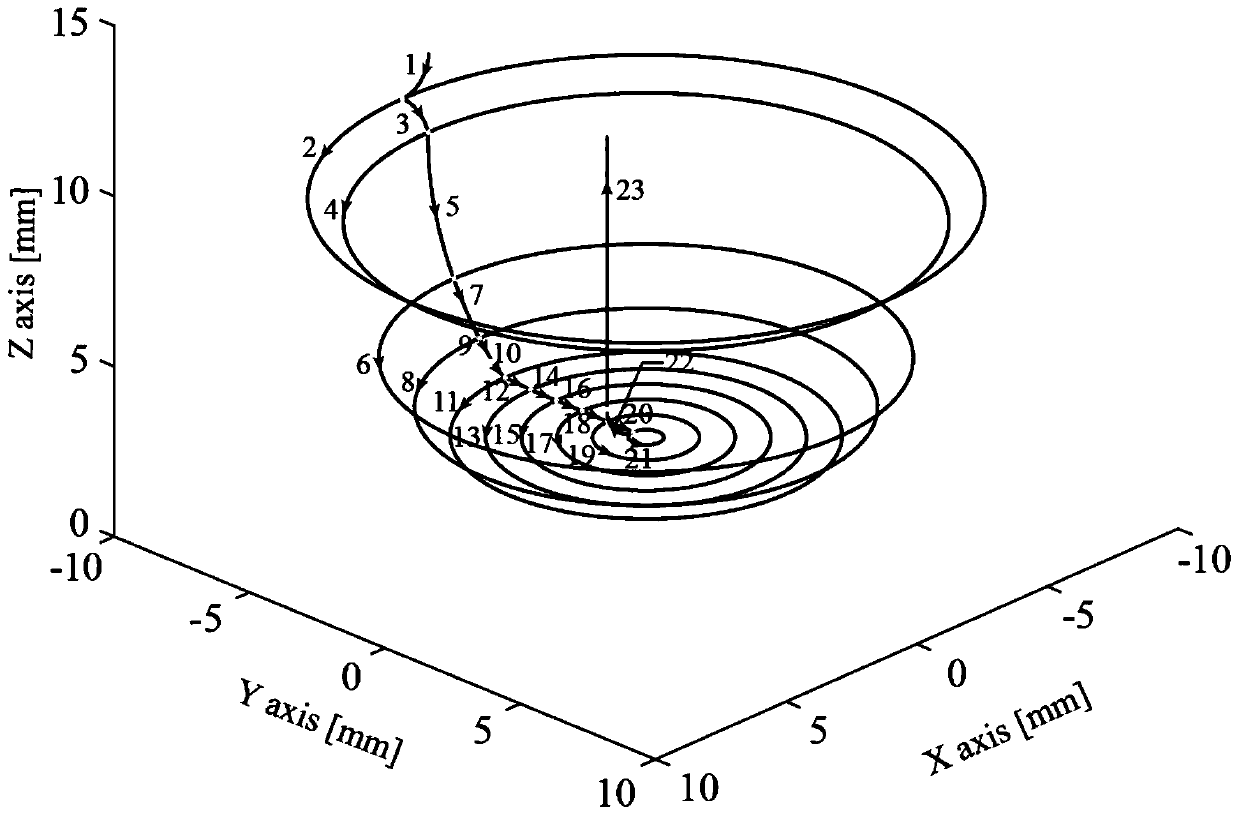

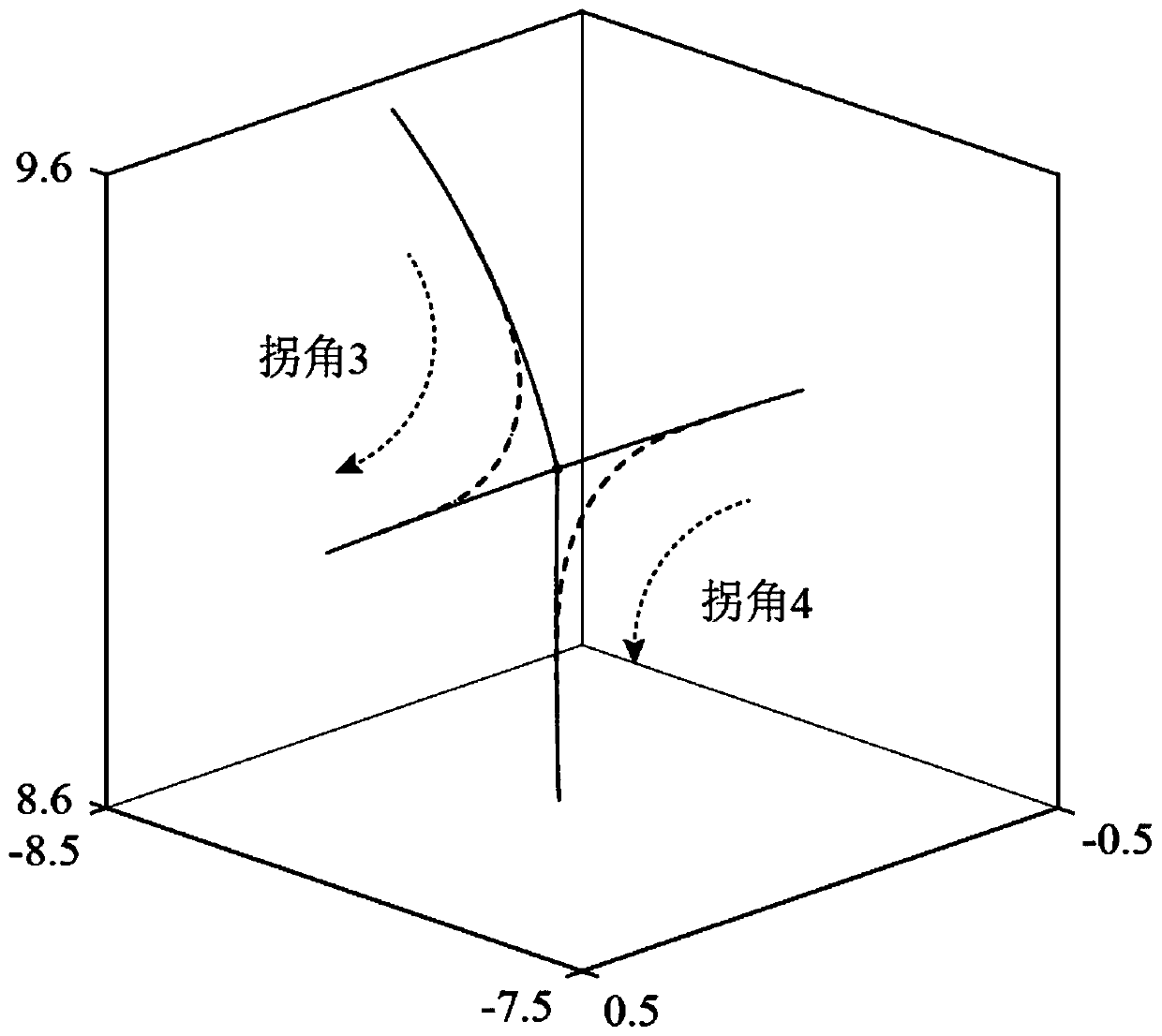

[0058] Reference Figure 1-7 . Select the tool path as a three-dimensional bowl-shaped path, in particular, the path includes G02 / G03 commands and space corners. The method of the invention is used to perform corner smoothing on the track, and the preset maximum smoothing error is 100um. Using the cubic acceleration method to plan the speed of the unsmoothed trajectory and the smoothed trajectory respectively, and obtain the speed curve and processing time of the two.

[0059] The specific steps of the spatial corner smoothing method based on the three-dimensional generalized Euler spiral of the present invention are as follows:

[0060] Step 1. Calculate the normal vector of the adjacent straight line segment or arc segment of the kth corner at the corner of space:

[0061]

[0062] v 1 Is the tangent vector of the previous line or arc at the corner, v 2 Is the tangent ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com