Method for adjusting primary and secondary reflectors of Cassegrain optical system

A secondary reflector and primary reflector technology, applied in optics, optical components, installation, etc., can solve the limitation of installation and adjustment accuracy, it is difficult to meet the installation and adjustment accuracy requirements of high-precision Cassegrain system, and it is impossible to measure the aspheric optical axis deviation and other problems, to achieve the effect of high efficiency of installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

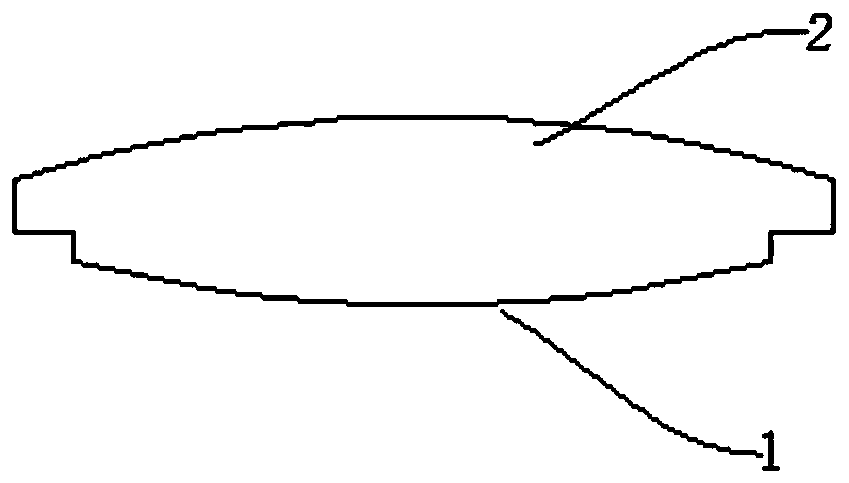

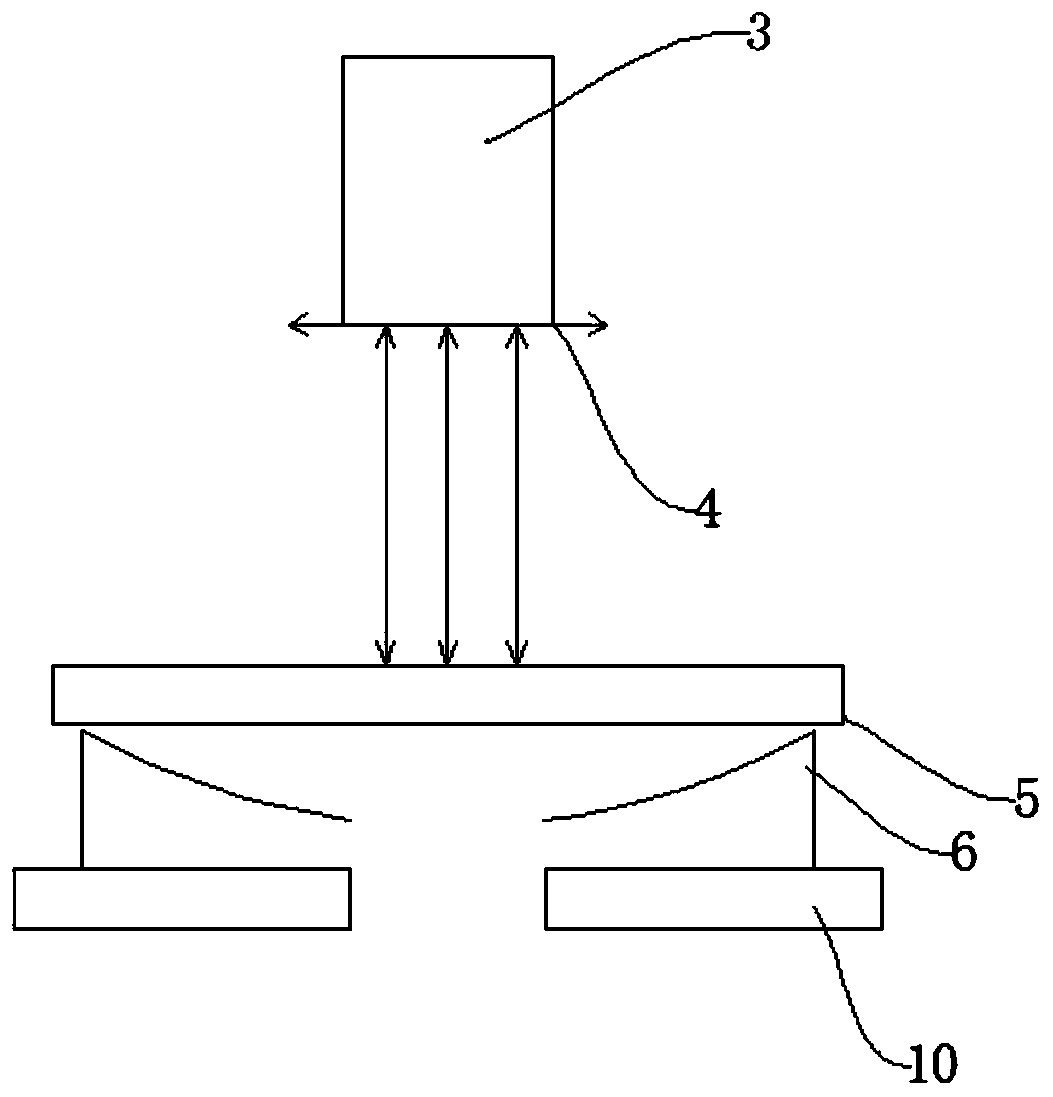

[0032] Embodiment 1: The method for installing and adjusting the primary and secondary reflectors of the Segling optical system, specifically including the adjustment of the primary reflector, the assembly and adjustment of the secondary reflectors, and the adjustment of the interval between the primary and secondary reflectors.

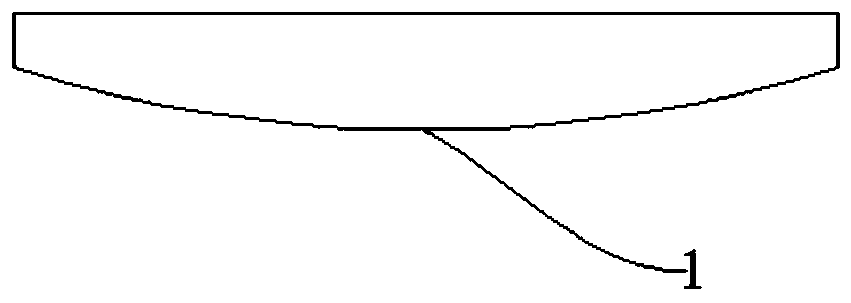

[0033] First of all, a technical spherical surface needs to be designed on the secondary reflector. The technical spherical surface and the secondary reflector are integrally processed. It is a spherical surface designed to meet the use of the central deviation measuring instrument. The technical spherical surface does not participate in the imaging of the optical system. The primary and secondary reflectors are made of opaque aluminum alloy, and the technical spherical surface is also made of aluminum alloy, which is polished after processing.

[0034] Second, carry out the adjustment of the main reflector, the specific steps are as follows:

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com