Part cracking inspection device

A technology for testing devices and parts, which is applied in the direction of measuring the rate of increase and deceleration of fluids, instruments, electrical transmission signal systems, etc., to achieve the effects of reducing the lag of production progress, reducing manual intervention, and comprehensive adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

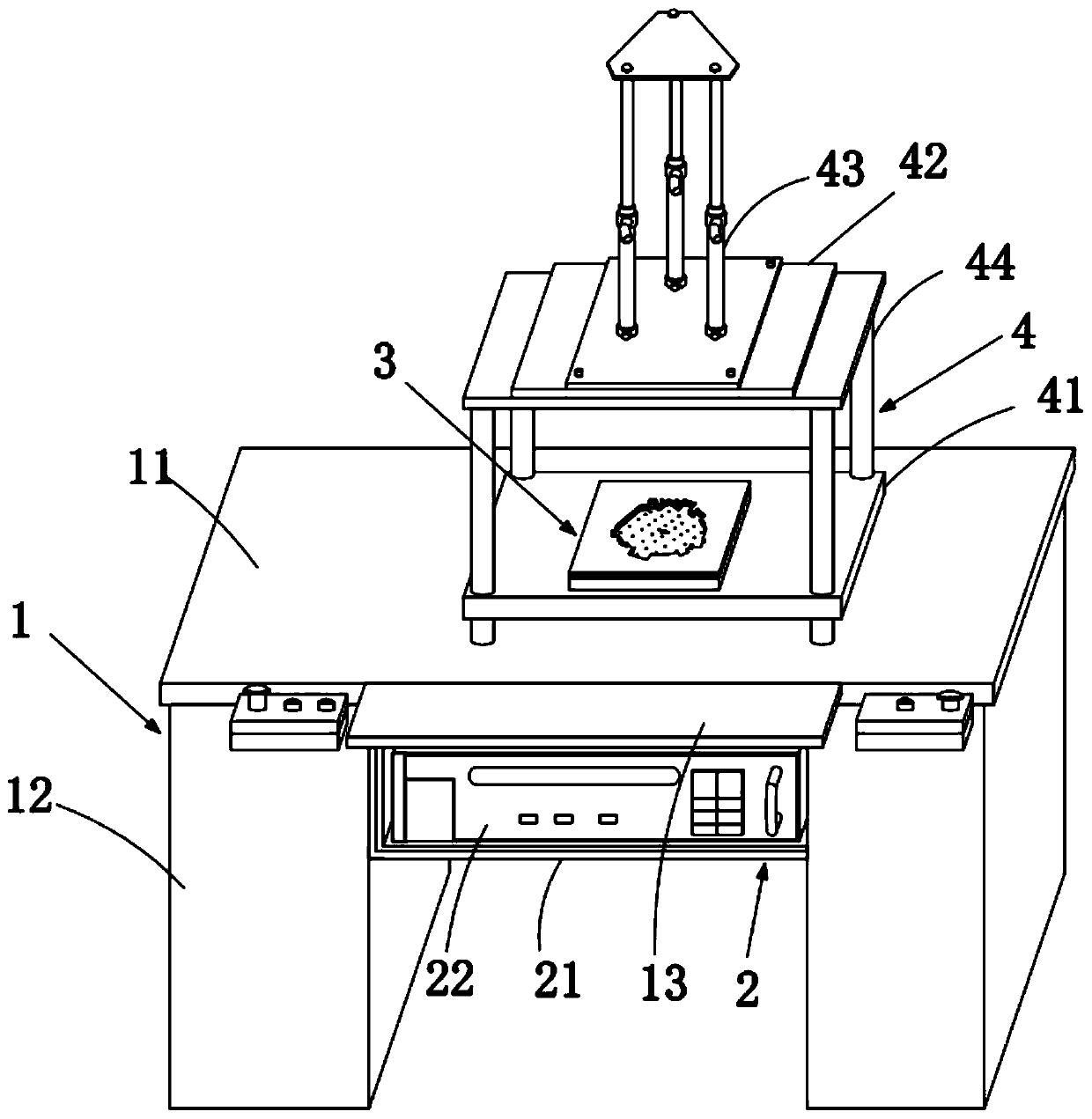

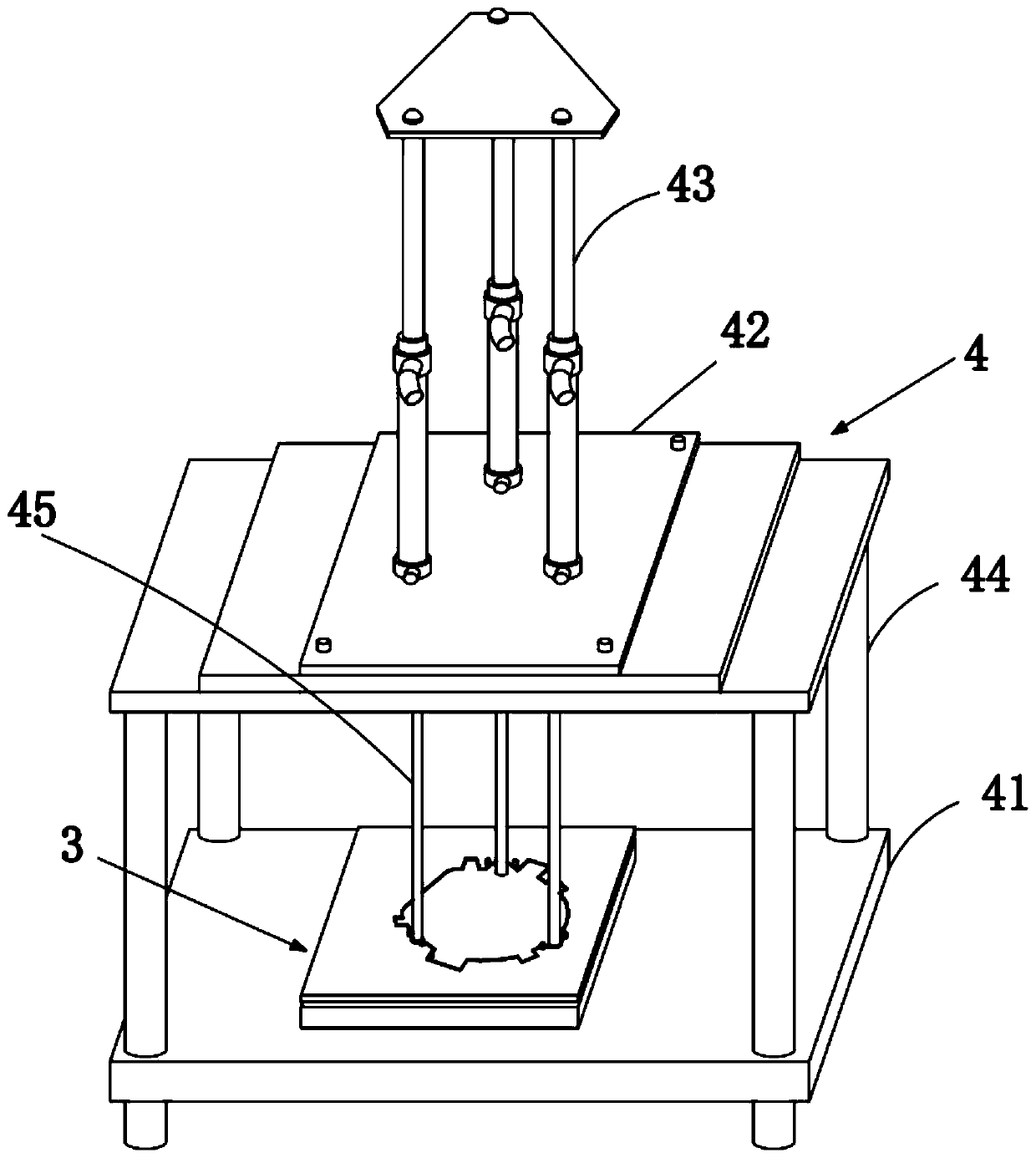

[0025] Such as figure 1 As shown, a part cracking inspection device includes a support mechanism 1 for supporting and fixing various components, a detection mechanism 2 for providing a stable pressure gas, a detection tool 3 for placing parts and forming a closed space, and a detection tool for placing parts The fixed fixing mechanism 4, the supporting mechanism 1 installs and supports the testing mechanism 2, the testing tooling 3 and the fixing mechanism 4, the testing mechanism 2 inflates and measures pressure during testing, the testing tooling 3 engages the parts, and the fixing mechanism 4 presses the parts together On the top of the detection tool 3, a relatively airtight space is formed between the parts and the tool. The detection mechanism 2 is used to inflate and maintain pressure to measure and judge whether there is gas leakage in the space, thereby realizing the detection of cracks in the parts.

[0026] Such as figure 1 As shown, the detection mechanism 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com