Method for impact prevention when deep well thick coal seam complicated geological condition multi-factor-coupled high-stress region passing connection roadways

A technology with complex geological conditions and deep wells and thick coal seams, which is applied to drilling equipment and methods, ground mining, earthwork drilling and mining, etc., and can solve problems such as the inability to maintain a balanced and stable advancement of the working face, poor anti-scouring safety, and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

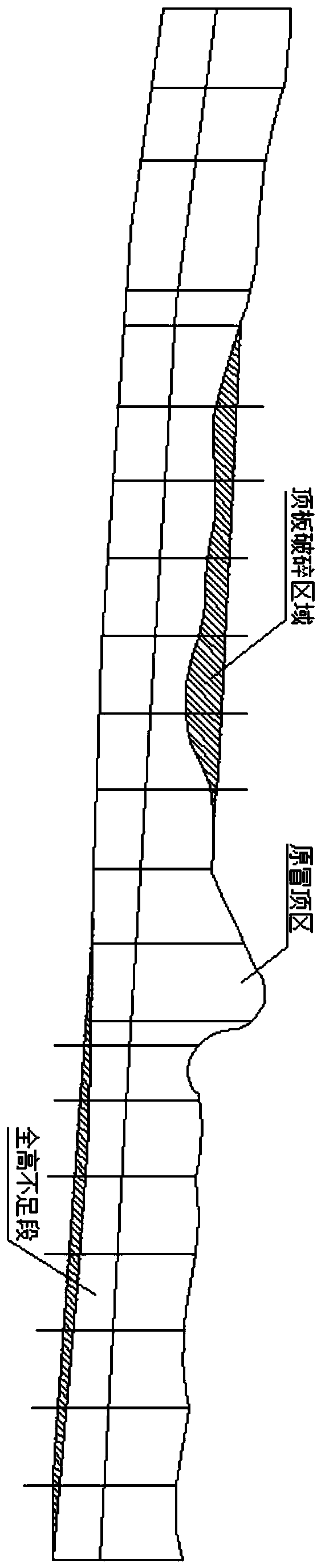

[0034] S1: Rework of connection roadway: Rework and roof reinforcement of the connection roadway were carried out in advance, and partial undercover and roof lifting were carried out to ensure the height of the roadway to be 3.5m;

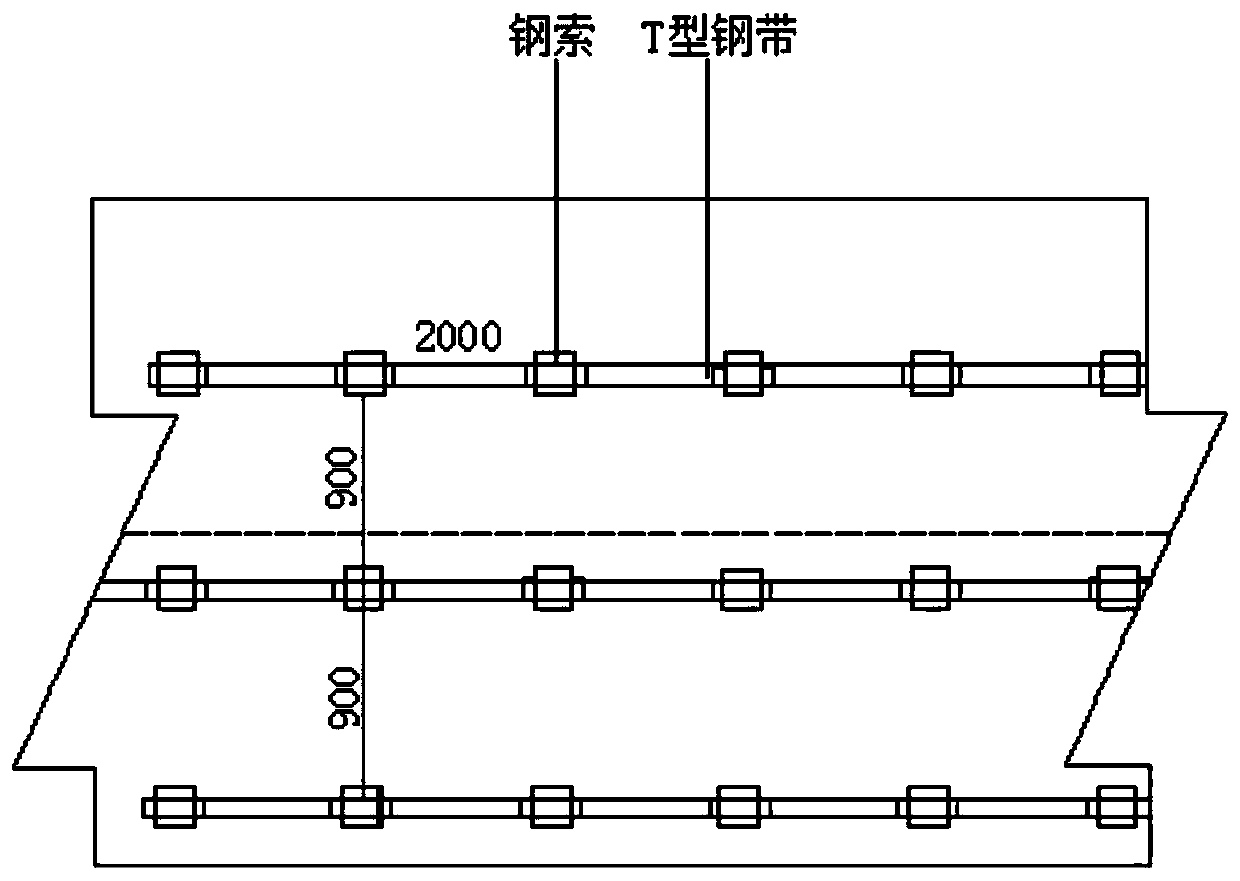

[0035]S2: Roof reinforcement: The roof is reinforced with Ф21.6 anchor cables and 2.4m T-shaped steel belts. The T-shaped steel belts are arranged in a step-like manner along the direction of the roadway, perpendicular to the original roadway support W steel belts, and each steel belt is equipped with 3 anchors Anchor cables are used for anchoring, the row spacing between anchor cables is 0.9m*2.0m, and anchor cable pallets of 300×300×16mm are used for anchoring;

[0036] S3: Reinforced support: wooden piles are built within 10m at both ends, and 5 wooden piles at each end are filled with gangue bags. The distance between wooden piles in the middle is 15m each. There are two slab girders on each floor, and the uppermost slab girder shall be connect...

Embodiment 2

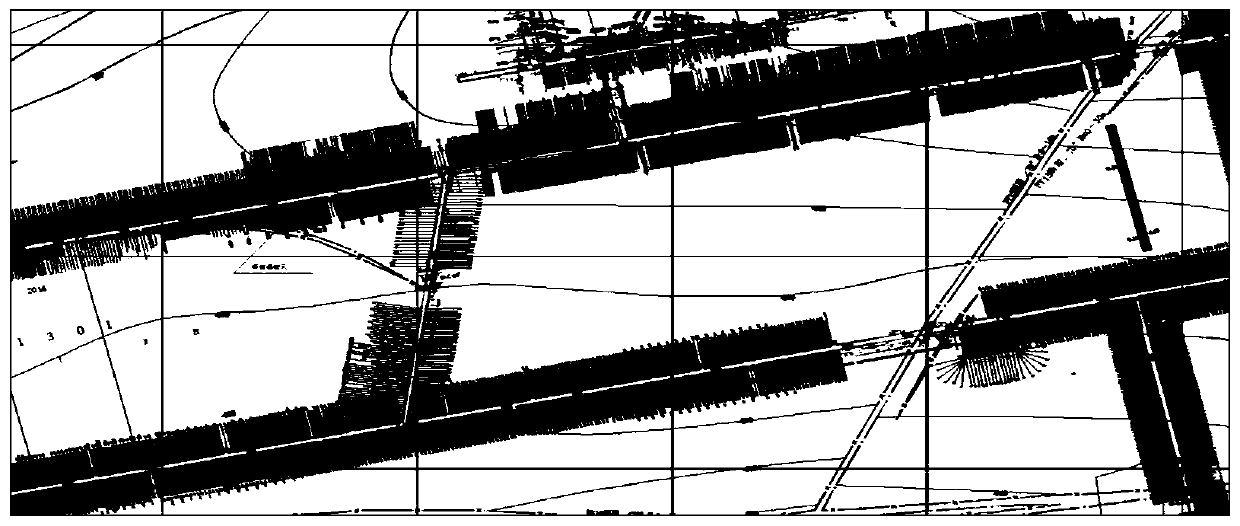

[0045] The maximum influence range of the leading abutment pressure reaches 220m when the working face passes through the tie-way, which is much larger than 120m during the period of the comparison ratio. However, there is no 10 5 J event, appear 10 4 J event 8 times, maximum energy event 4.5*10 4 J, the number and energy of events are much smaller than the period of over-contrast ratio;

[0046] During the time when the working face passes through the connecting lane, there are early warnings of individual stress monitoring points in the two troughs, but there are no simultaneous early warnings of multiple sets of stress gauges when there is no comparison ratio;

[0047] Compared with the average advance speed of 3 knives per day during the implementation period, the advancing speed during the passage of the connecting lane was basically maintained at 4 knives per day, an average of one more knives per day was advanced, the output was increased by 2100 tons, the economic ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com