Novel pre-buried unit type ultra-long life multi-directional deflection bridge telescopic device

A super long-life, multi-directional displacement technology, applied in the field of bridge expansion joints, can solve the problems of uneven tooth plate, easy to cause traffic accidents, warping, etc., to strengthen the firmness and strength, shorten the installation period, and increase the number of welding parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

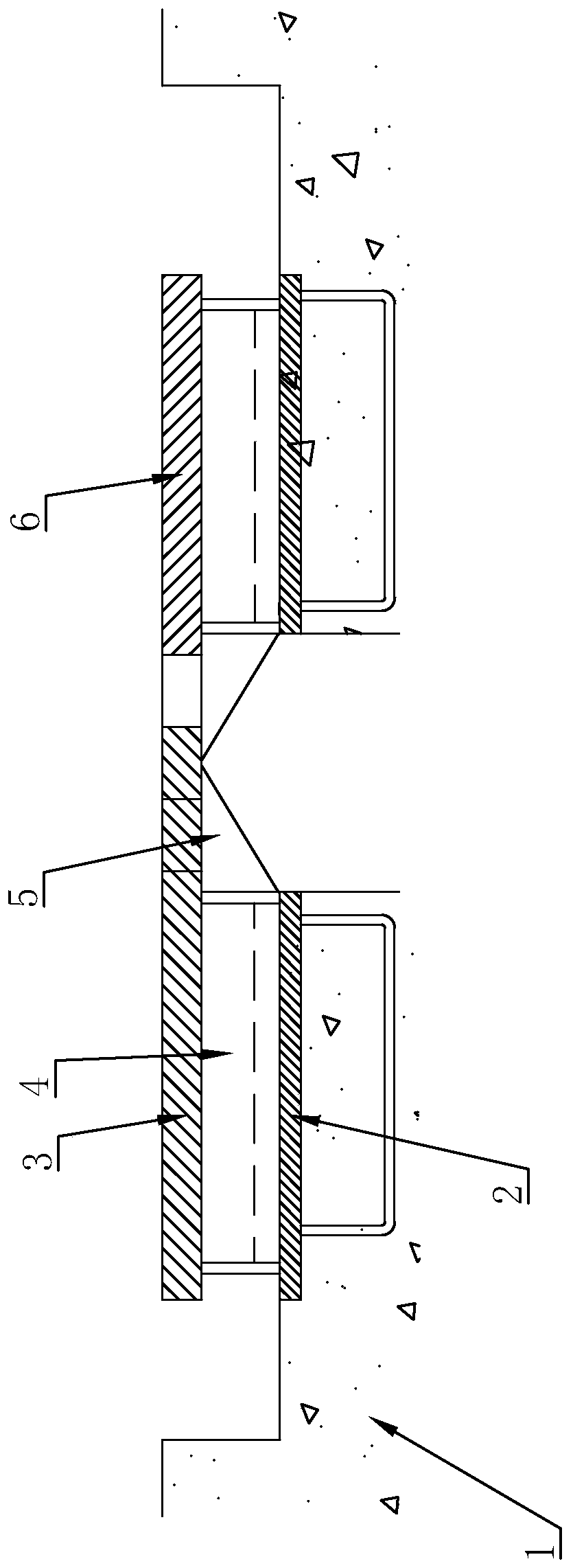

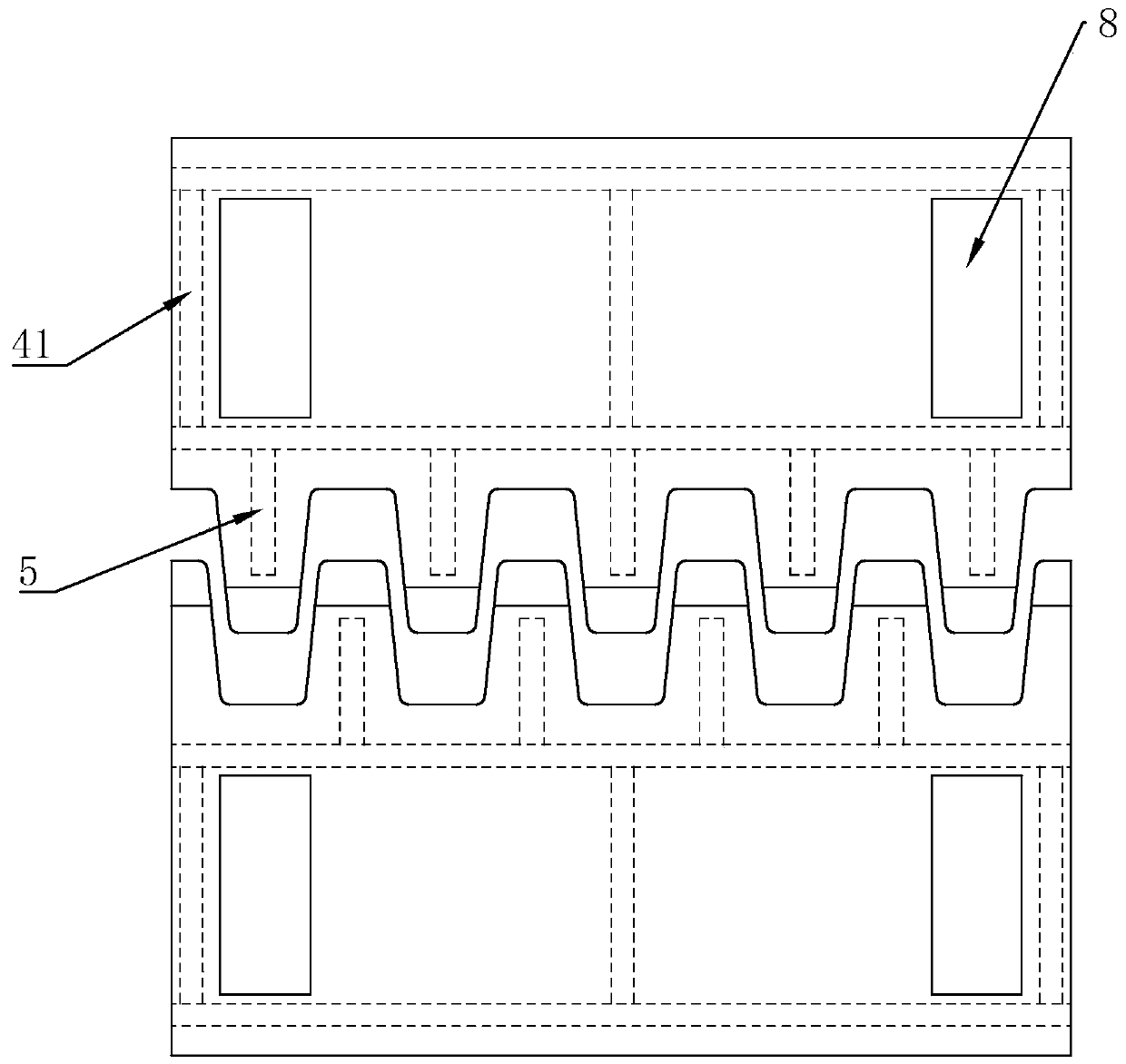

[0020] Such as Figure 1-Figure 2 As shown, the present invention provides a new pre-embedded unit type ultra-long life multi-directional displacement bridge telescopic device, including a main tooth plate 3 and an auxiliary tooth plate 6, and the main tooth plate 3 is installed on the first bridge girder body 1, The auxiliary tooth plate 6 is installed on the second bridge beam body 7, the comb teeth of the main tooth plate 3 and the auxiliary tooth plate 6 cross each other and have gaps, and are located between the first bridge beam body 1 and the second bridge beam body 7 Above the gap, steel plates 2 are preset between the main tooth plate 3 and the first bridge beam body 1, and between the auxiliary tooth plate 6 and the second bridge beam body 7, and the steel plates 2 are respectively connected to the first bridge beam body through the anchor ring 1. The second bridge beam body 7 is fixed, and the lower part of the main tooth plate 3 and the auxiliary tooth plate 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com