Black hot-melt adhesive tape, preparation process therefor and application of black hot-melt adhesive tape

A hot-melt tape and preparation process technology, applied in adhesives, heat-activated films/sheets, record carriers used in machines, etc., can solve problems such as chip damage, reduce operating costs, improve laser blocking performance, and achieve significant economic benefits. and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

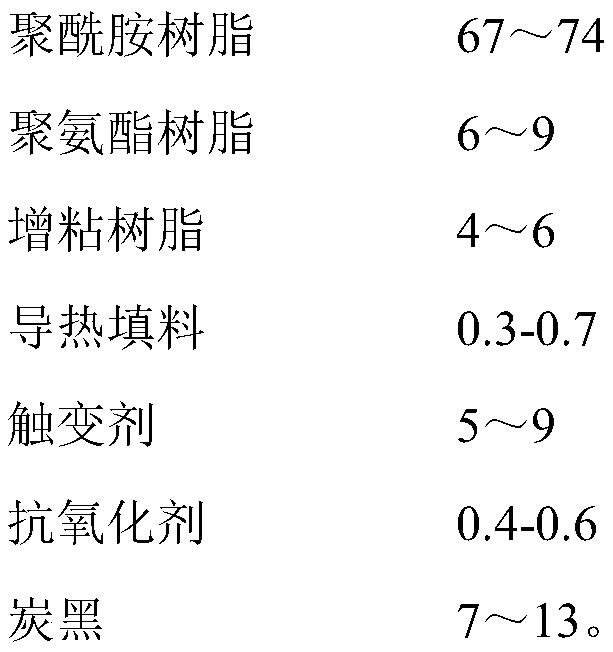

[0033] The present embodiment provides a kind of black hot-melt adhesive tape, comprises release layer and adhesive film layer; The upper surface of release layer is coated with adhesive film layer, and the thickness of adhesive film layer is 40 μ m, and adhesive film comprises following components by weight:

[0034]

[0035] Thermally conductive fillers are calcium carbonate and talcum powder.

[0036] The thixotropic agent is fumed silica.

[0037] The antioxidant is Antioxidant 1010.

[0038] The release layer is release paper, and the material of the release paper is double-sided silicone oil glassine paper.

[0039] The preparation technology of black hot-melt adhesive tape, comprises the steps:

[0040] S1. Blend the polyamide resin, polyurethane resin and carbon black in a twin-screw extruder first, the extrusion temperature is 140°C, and the screw speed of the twin-screw extruder is 20r / min, so that the carbon black is in the rubber particle system Evenly disper...

Embodiment 2

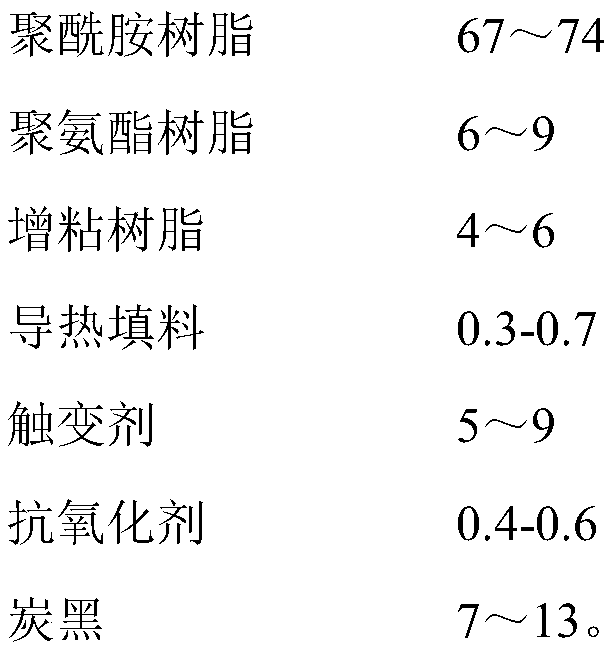

[0044] The present embodiment provides a kind of black hot-melt adhesive tape, comprises release layer and adhesive film layer; The upper surface of release layer is coated with adhesive film layer, and the thickness of adhesive film layer is 60 μ m, and adhesive film comprises following components by weight:

[0045]

[0046] The thermally conductive filler is zinc oxide.

[0047] Thixotropic agents are talc and paraffin.

[0048] The antioxidant is Antioxidant 1010.

[0049] The release layer is release paper, and the material of the release paper is double-sided silicone oil glassine paper.

[0050] The preparation technology of black hot-melt adhesive tape, comprises the steps:

[0051] S1. Blend the polyamide resin, polyurethane resin and carbon black in a twin-screw extruder first, the extrusion temperature is 160°C, and the screw speed of the twin-screw extruder is 30r / min, so that the carbon black is in the rubber particle system Evenly dispersed;

[0052] S2, t...

Embodiment 3

[0055] The present embodiment provides a kind of black hot-melt adhesive tape, comprises release layer and adhesive film layer; The upper surface of release layer is coated with adhesive film layer, and the thickness of adhesive film layer is 80 μ m, and adhesive film comprises following components by weight:

[0056]

[0057] The thermally conductive fillers are barium oxide and barium sulfate.

[0058] The thixotropic agent is rosin resin.

[0059] The antioxidant is Antioxidant 1010.

[0060] The release layer is release paper, and the material of the release paper is double-sided silicone oil glassine paper.

[0061] The preparation technology of black hot-melt adhesive tape, comprises the steps:

[0062] S1. Blend the polyamide resin, polyurethane resin and carbon black in a twin-screw extruder first, the extrusion temperature is 180°C, and the screw speed of the twin-screw extruder is 40r / min, so that the carbon black is in the rubber particle system Evenly dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com