Anti-rust printing ink

A technology of ink and resin, which is applied in the field of anti-rust ink, can solve the problems of easy rust, affecting the packaging of metal products, ink falling off, etc., and achieve the effect of preventing rust, preventing damp and rust, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

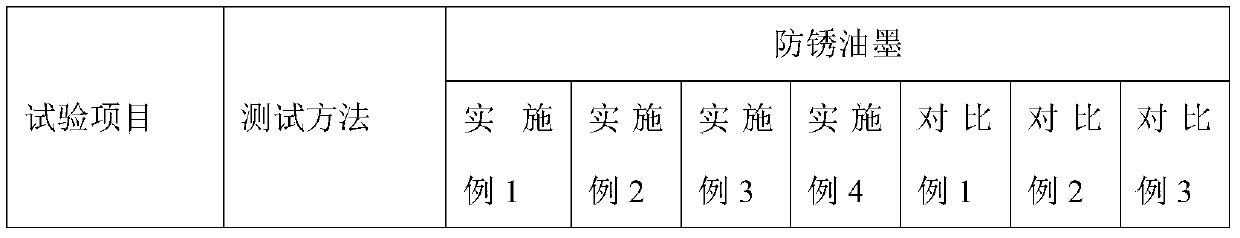

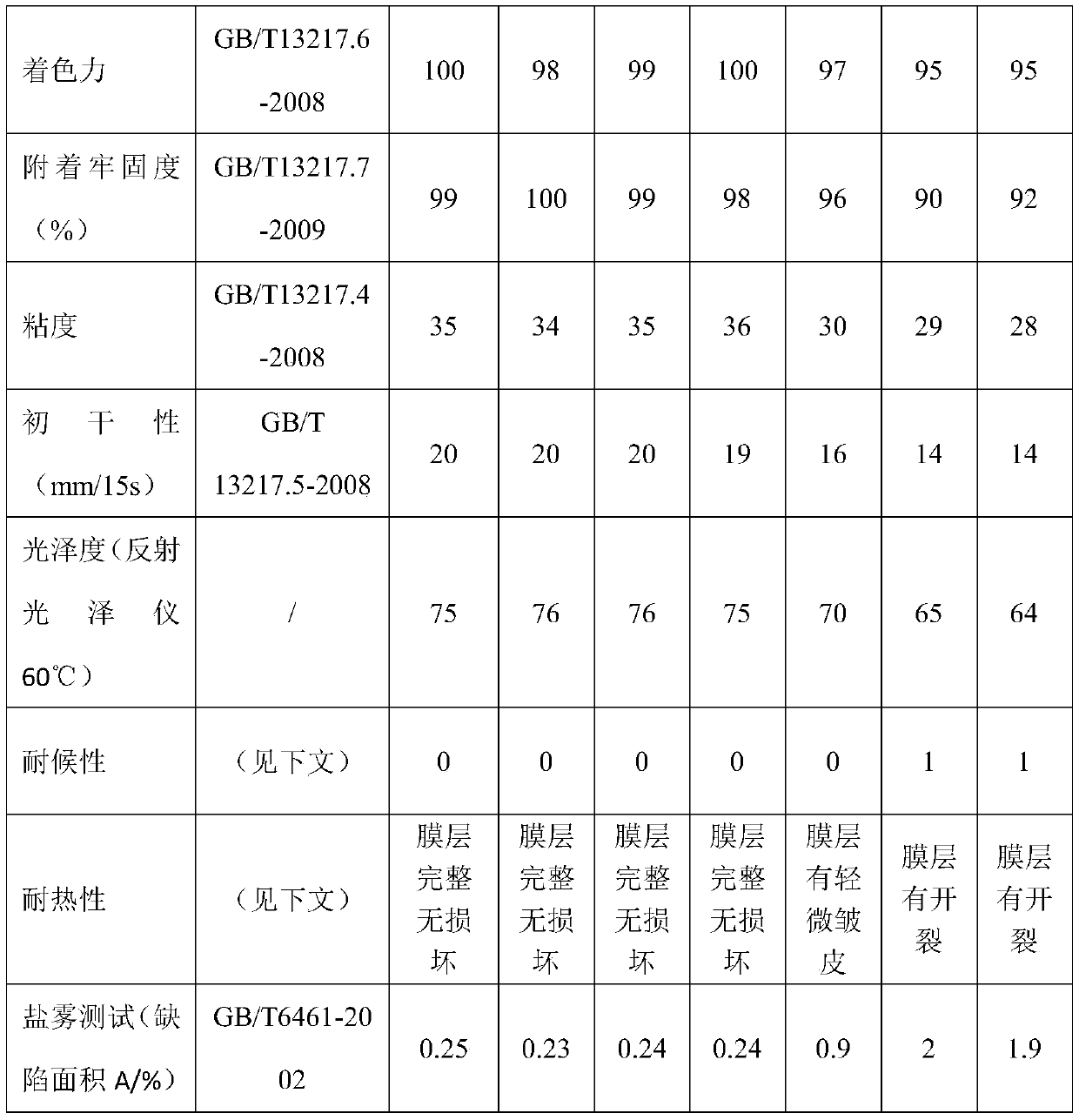

Examples

Embodiment 1

[0035] A kind of antirust ink, comprises 27 parts of water-based polyurethane resins, 25 parts of water-based acrylic resins, 5 parts of pigments, 3.5 parts of polyurethane thickeners, 0.2 parts of polyacid copolymer dispersants, 5.5 parts of alcohol amine modified amorphous silica anti-rust Rust filler, 32 parts ethanol, 13 parts deionized water.

[0036] Wherein, the alcohol amine modified amorphous silica antirust filler in embodiment 1 is prepared by the following method:

[0037] Add 5000 grams of 10wt% sulfuric acid solution in the reactor, then add 20wt% water glass solution to adjust the pH of the system to be 1; the time for adding the water glass solution is 60 minutes; stir evenly and let stand for 90 minutes, the reaction temperature is 40°C ; After standing still, adjust the pH value of the mixed solution to 8 with 10% sodium hydroxide solution, and simultaneously heat up to 90° C., and keep it for 60 minutes; adjust the pH value of the system to 3 with 10% sulfur...

Embodiment 2

[0042] A kind of antirust ink, comprises 27 parts of water-based polyurethane resins, 25 parts of water-based acrylic resins, 5 parts of pigments, 3.5 parts of polyurethane thickeners, 0.2 parts of polyacid copolymer dispersants, 5.5 parts of alcohol amine modified amorphous silica anti-rust Rust filler, 32 parts ethanol, 13 parts deionized water.

[0043] Wherein, the alcohol amine modified amorphous silica antirust filler in embodiment 2 is prepared by the following method:

[0044] Add 5000 grams of 30wt% sulfuric acid solution in the reaction kettle, then add 20wt% water glass solution to adjust the pH value of the system to 1.5; the time for adding the water glass solution is 30 minutes; after stirring evenly, let it stand for 90 minutes, and the reaction temperature is 50°C ; After standing, adjust the pH value of the mixed solution to 8 with 10% sodium hydroxide solution, and simultaneously heat up to 90° C., and keep it for 30 minutes; adjust the pH value of the system...

Embodiment 3

[0048] A kind of antirust ink, comprises 27 parts of water-based polyurethane resins, 25 parts of water-based acrylic resins, 5 parts of pigments, 3.5 parts of polyurethane thickeners, 0.2 parts of polyacid copolymer dispersants, 5.5 parts of alcohol amine modified amorphous silica anti-rust Rust filler, 32 parts ethanol, 13 parts deionized water.

[0049] Wherein, the alcohol amine modified amorphous silica antirust filler in embodiment 3 is prepared by the following method:

[0050] Add 5000 grams of 30wt% sulfuric acid solution in the reaction kettle, then add 20wt% water glass solution to adjust the pH of the system to be 1.5; the time for adding the water glass solution is 60 minutes; stir evenly and let stand for 90 minutes, and the reaction temperature is 50°C ; After standing, adjust the pH value of the mixed solution to 8 with 10% sodium hydroxide solution, and simultaneously heat up to 90° C., and keep it for 30 minutes; adjust the pH value of the system to 3.5 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com