Ultraviolet blocking ternary nano composite membrane material and preparation method thereof

A nano-composite and UV-blocking technology is applied in the field of UV-blocking ternary nano-composite film materials and their preparation, which can solve the problems of complex preparation process and achieve the effects of simple and easy process, superior UV-blocking performance and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

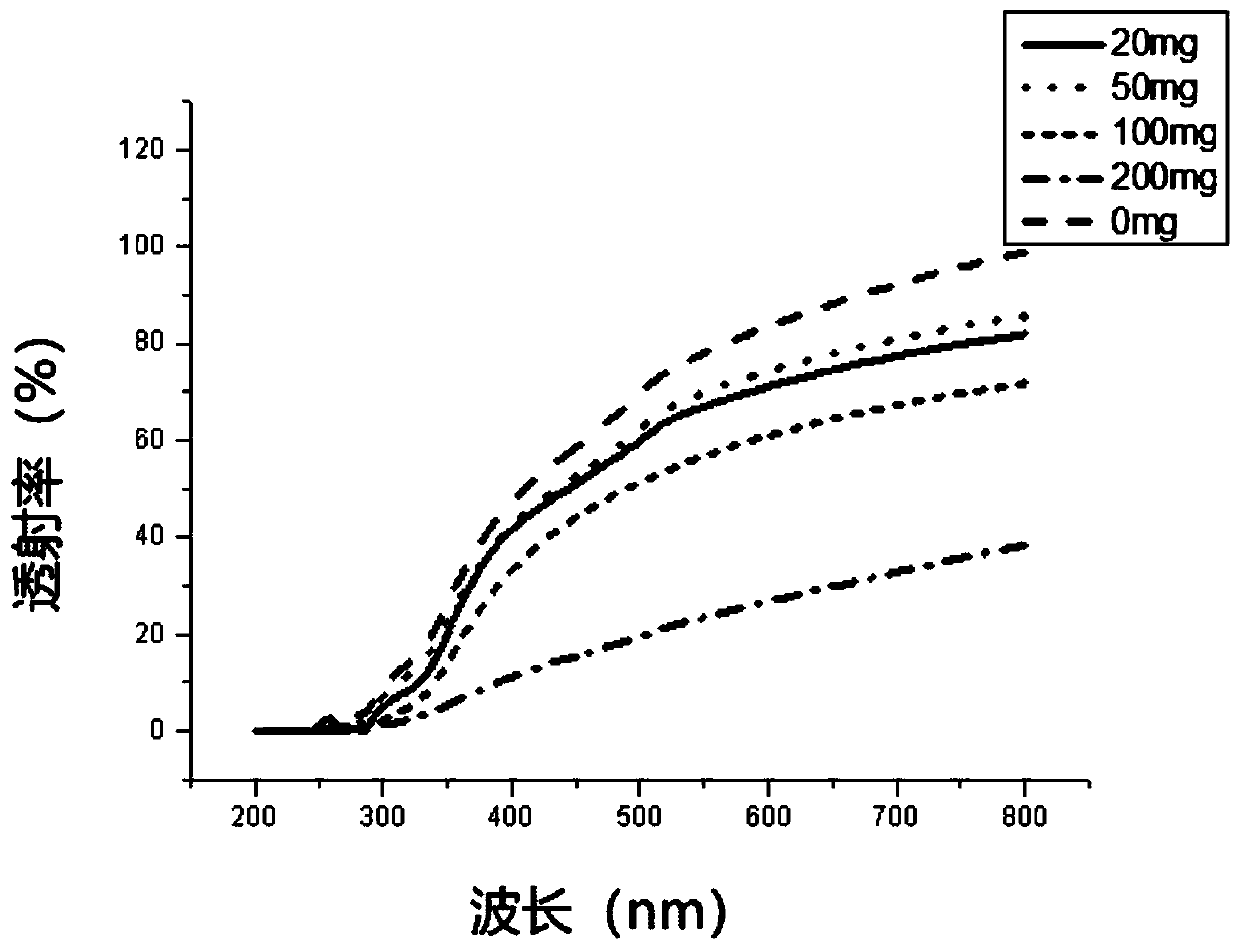

[0034] This embodiment provides a method for preparing a UV-blocking ternary nanocomposite film material, comprising the following steps:

[0035] (1) Fully dissolve 600 mg of zein in 50 ml of 75% ethanol aqueous solution at 60°C, heat and reflux at 60°C and stir for 15 minutes to obtain a protein solution;

[0036] (2) Add 20 mg of cerium nitrate hexahydrate, 24 mg of urea, and 1.8 g of polyvinylpyrrolidone to the protein solution in sequence at 60°C, adjust the pH to 8 with 1mol / L sodium hydroxide solution, then add 100 μL of glycerol and 100 μL of Tween-80, reflux and stir at 60°C for 15 minutes, then raise the temperature to 80°C and continue stirring for 2 minutes to obtain a composite solution;

[0037] (3) Filtrate the composite solution under reduced pressure to obtain a film-forming solution. Apply the film-forming solution evenly on a glass slide, and vacuum-dry it at 80°C for 24 hours to obtain an ultraviolet-blocking ternary nanocomposite film material, that is, a ...

Embodiment 2

[0039] This embodiment provides a method for preparing a UV-blocking ternary nanocomposite film material, comprising the following steps:

[0040] (1) Fully dissolve 600 mg of zein in 50 ml of 75% ethanol aqueous solution at 60°C, heat and reflux at 60°C and stir for 15 minutes to obtain a protein solution;

[0041] (2) Add 50 mg of cerium nitrate hexahydrate, 60 mg of urea and 1.8 g of polyvinylpyrrolidone to the protein solution in sequence at 60 °C, adjust the pH to 8 with 1 mol / L sodium hydroxide solution, then add 100 μL of glycerol and 100 μL of Tween-80, reflux and stir at 60°C for 15 minutes, then raise the temperature to 80°C and continue stirring for 2 minutes to obtain a composite solution;

[0042] (3) Filter the composite solution under reduced pressure to obtain a film-forming solution. Apply the film-forming solution evenly on a glass slide, and vacuum-dry it at 80°C for 24 hours to obtain an ultraviolet-blocking ternary nanocomposite membrane material, namely C...

Embodiment 3

[0044] This embodiment provides a method for preparing a UV-blocking ternary nanocomposite film material, comprising the following steps:

[0045] (1) Fully dissolve 600 mg of zein in 50 ml of 75% ethanol aqueous solution at 60°C, heat and reflux at 60°C and stir for 15 minutes to obtain a protein solution;

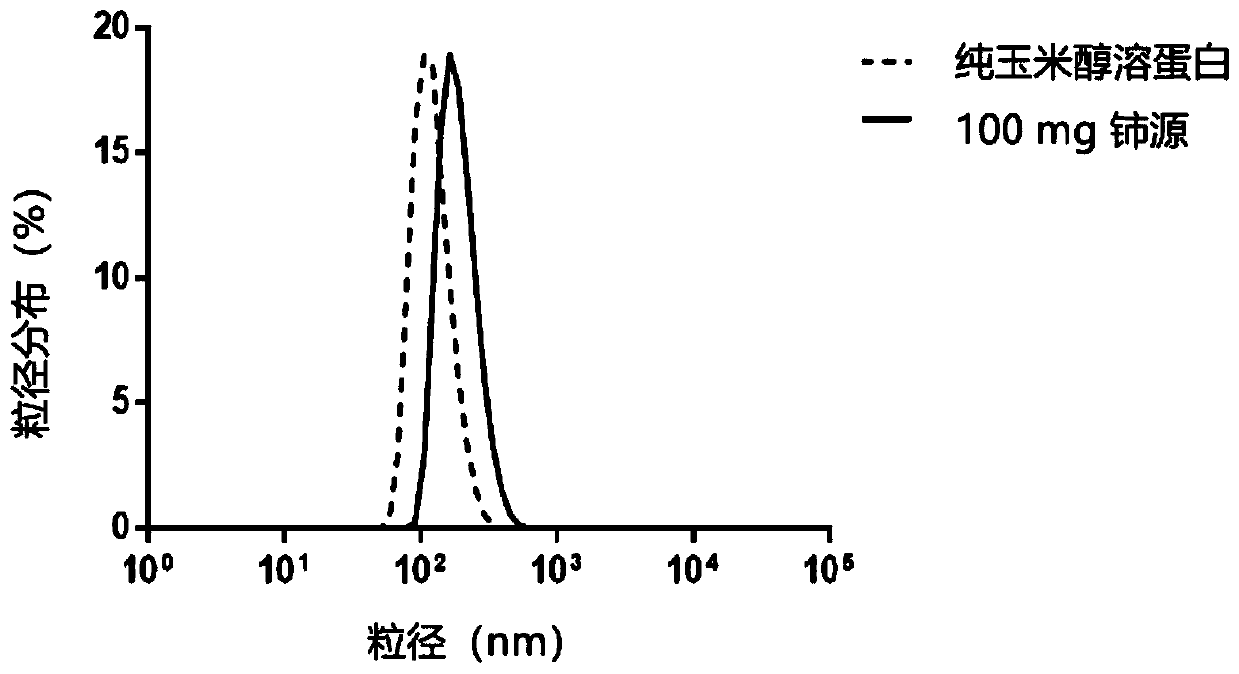

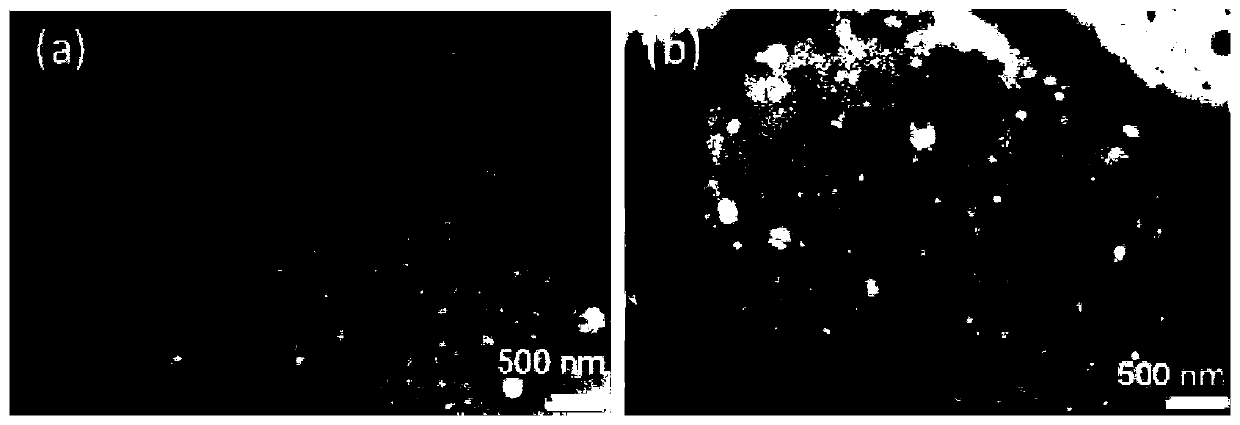

[0046](2) Add 100 mg of cerium nitrate hexahydrate, 120 mg of urea and 1.8 g of polyvinylpyrrolidone to the protein solution in sequence at 60°C, adjust the pH to 8 with 1mol / L sodium hydroxide solution, then add 100 μL of glycerol and 100 μL of Tween-80, reflux and stir at 60°C for 15 minutes, then raise the temperature to 80°C and continue stirring for 2 minutes to obtain a composite solution;

[0047] (3) Filter the composite solution under reduced pressure to obtain a film-forming solution. Apply the film-forming solution evenly on a glass slide, and vacuum-dry it at 80°C for 24 hours to obtain an ultraviolet-blocking ternary nanocomposite membrane material, namely Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com