Porous ceramic for electronic cigarette device and preparation method thereof

A technology of porous ceramics and electronic cigarettes, which is applied in the field of electronic cigarettes, can solve problems such as the inability to satisfy consumers' puffing frequency and taste, insufficient atomization of e-liquid, and influence on the amount of smoke, etc., to solve the problem of slow atomization speed of e-liquid, The effect of increasing the atomization rate of e-liquid and increasing the amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

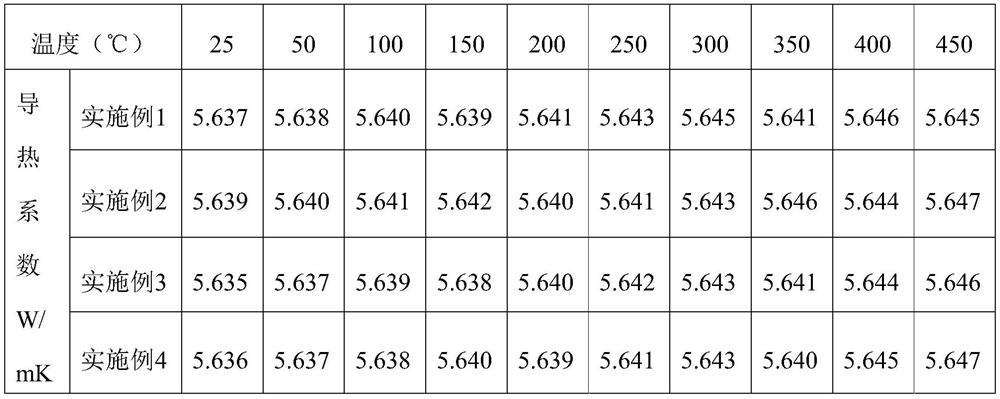

Examples

Embodiment 1

[0037] The preparation method of a porous ceramic for an electronic cigarette device of the present embodiment is as follows:

[0038] S1. By mass percentage, weigh 45% brown corundum, 12% green silicon carbide, 13% black silicon carbide, 3% Suzhou clay, 12% PVC, 7% PVB, 3% EVA, 2% SA and 3% respectively PW is added to the mixer for mixing and mixing, and the block-shaped ceramic mixer is obtained after mixing.

[0039] S2. Put the bulk ceramic banburying material obtained by banburying into a granulator to make a strip-shaped pellet feed with a length of 3-5 mm and a diameter of 2-3 mm suitable for injection molding.

[0040] S3. Perform injection molding on the pellet feed to obtain a ceramic embryo; the injection parameters are: the injection pressure is 72MPa, the speed is 58m / s, and the injection temperature is 152°C.

[0041] S4, put the ceramic body into a high-temperature degreasing furnace, heat up to 630° C. for thermal degreasing, and then keep the temperature for ...

Embodiment 2

[0045] The preparation method of a porous ceramic for an electronic cigarette device of the present embodiment is as follows:

[0046] S1, in terms of mass percentage, weigh 40% brown corundum, 10% black silicon carbide, 2% magnesium oxide, 3% silicon dioxide, 20% PE, 5% EVA and 11% SA, respectively, and add them into the mixer to carry out Mixing and banburying, the bulk ceramic banburying material is obtained after banburying.

[0047] S2. Put the bulk ceramic banburying material obtained by banburying into a granulator to make a strip-shaped pellet feed with a length of 3-5 mm and a diameter of 2-3 mm suitable for injection molding.

[0048] S3. Perform injection molding on the pellet feed to obtain a ceramic embryo; the injection parameters are: the injection pressure is 70MPa, the speed is 60m / s, and the injection temperature is 150°C.

[0049] S4. Put the ceramic body into a high-temperature degreasing furnace, heat it up to 650° C. for thermal degreasing, then keep the...

Embodiment 3

[0053] The preparation method of a porous ceramic for an electronic cigarette device of the present embodiment is as follows:

[0054] S1, in terms of mass percentage, weigh 55% brown corundum, 15% green silicon carbide, 4% silicon dioxide, 5% PVC, 5% PE, 10% SA and 6% PW, respectively, and add them to the mixer for mixing Banburying, after banburying, a block-shaped ceramic banburying material is obtained.

[0055] S2. Put the bulk ceramic banburying material obtained by banburying into a granulator to make a strip-shaped pellet feed with a length of 3-5 mm and a diameter of 2-3 mm suitable for injection molding.

[0056] S3. Perform injection molding on the pellet feed to obtain a ceramic embryo; the injection parameters are: the injection pressure is 65MPa, the speed is 55m / s, and the injection temperature is 155°C.

[0057] S4. Put the ceramic body into a high-temperature degreasing furnace, heat it up to 600° C. for thermal degreasing, then keep the temperature for 6.5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com