Passive bending and axial rotating mechanism based on cross reeds with variable cross sections

A technology of axial rotation and variable section, which is applied in the field of passive bending axial rotation mechanism, multi-stage passive bending deformation and axial rotation mechanical mechanism, which can solve the problem of unreachable passive deformation of bionic fish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

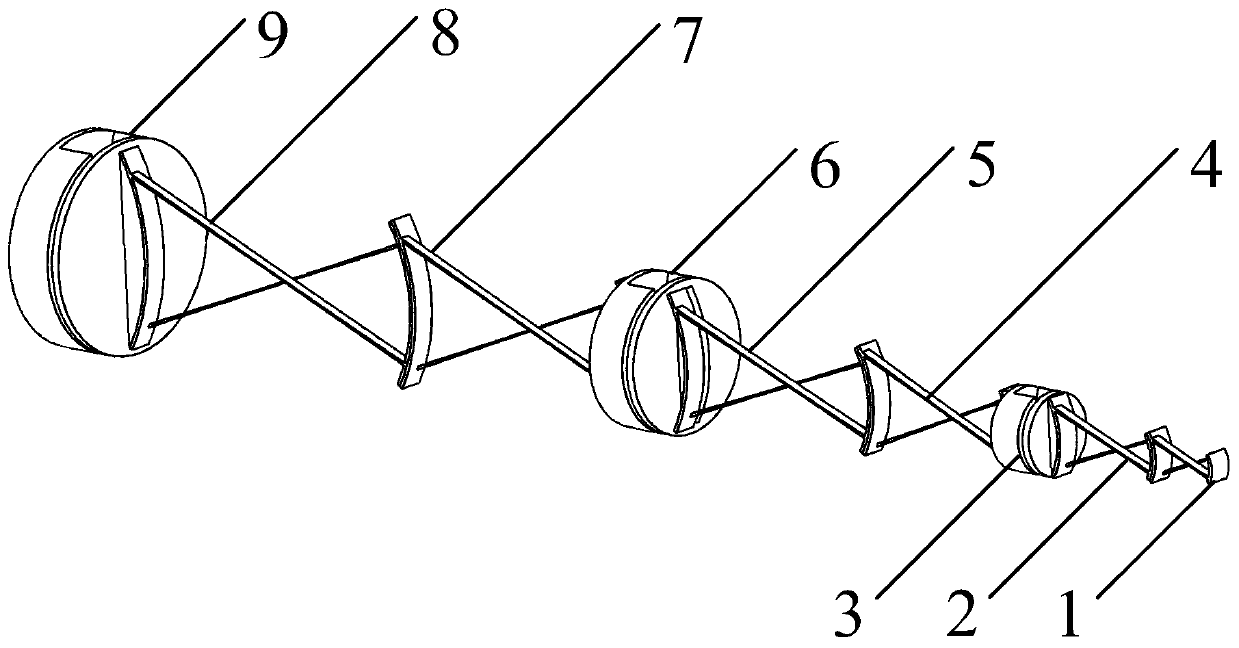

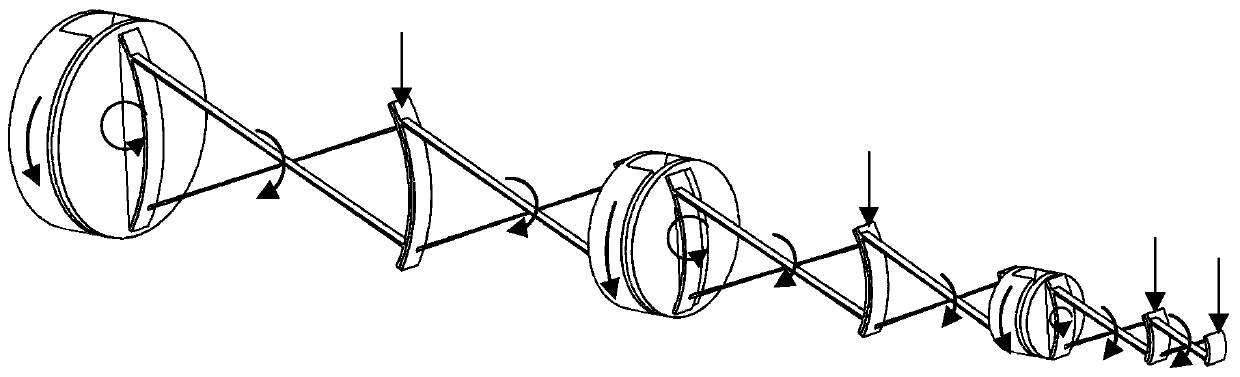

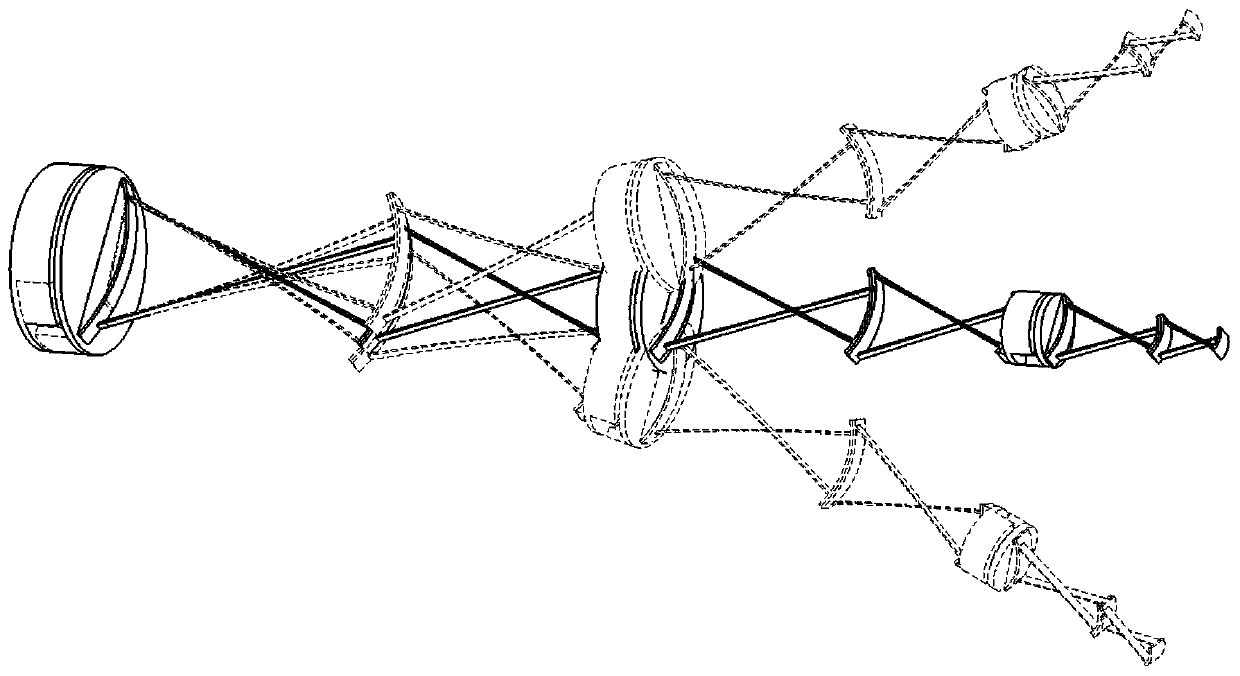

[0034] The overall structure of the embodiment of the present invention is shown in schematic figure 1, with six levels of cross reeds and three axially rotating cross reed units; the mechanism shown in the figure, the cross reeds that undertake the bending task are cross reeds with variable cross-sections, and the two ends are connected to the free ends of the arc surface. An axially rotating cross-reed unit is connected between the two-stage curved cross-reed units, which are distributed according to the order: No. 1 curved cross-reed unit 1 connects to No. 2 curved cross-reed unit 2, and then connects to No. 1 The axially rotating cross reed unit 3 is connected to the No. 3 curved cross reed unit 4 and the No. 4 curved cross reed unit 5 in turn, and then connected to the No. 2 axially rotating cross reed unit 6, and connected to No. 5 in turn The No. 6 curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com