EHD printing preparation method of flexible thermoelectric device

A thermoelectric device and flexible technology, applied in the field of 3D printing, can solve the problems of difficult power supply, high density, and large size of wearable electronic devices, and achieve good industrialization prospects, low power consumption, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

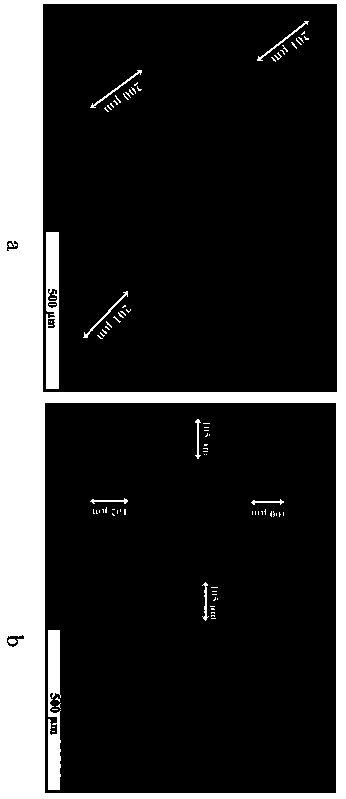

[0027] The following further describes the embodiments of the present invention with reference to the drawings:

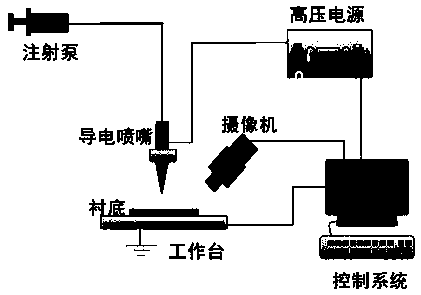

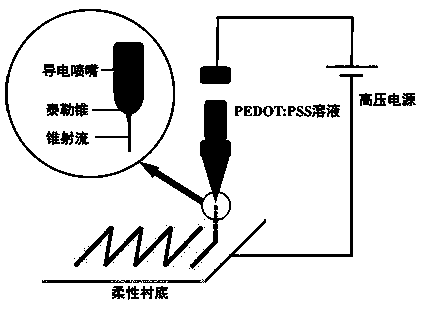

[0028] The present invention provides a method for preparing EHD printing of flexible thermoelectric devices. Based on EHD printing equipment, the printing material is a conductive polymer PEDOT:PSS dispersion, which comprises the following steps:

[0029] 1) Use surfactants to adjust the surface tension of conductive polymer PEDOT:PSS dispersion;

[0030] First, measure the PEDOT:PSS solution, add an appropriate amount of Triton X-100, and stir thoroughly. The amount of Triton X-100 is 0.1-5 wt% to make it fully mixed and achieve the purpose of adjusting the surface tension;

[0031] 2) Move the conductive polymer PEDOT:PSS dispersion completed in step 1) to the EHD printing device, and adjust the printing parameters of the EHD printing device; printing parameters include voltage, electrode distance, and liquid flow

[0032] Speed, needle selection, etc.;

[0033] 3) Perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com