Air-cooled large-diameter shield segment condenser pipe device and construction method

A technology of shield segment and construction method, which is applied in steam/steam condensers, manufacturing tools, auxiliary forming equipment, etc., can solve the problems of segment performance not meeting the design requirements, easy to generate cracks, etc., and achieve high practical value , reduce engineering water use, and have strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

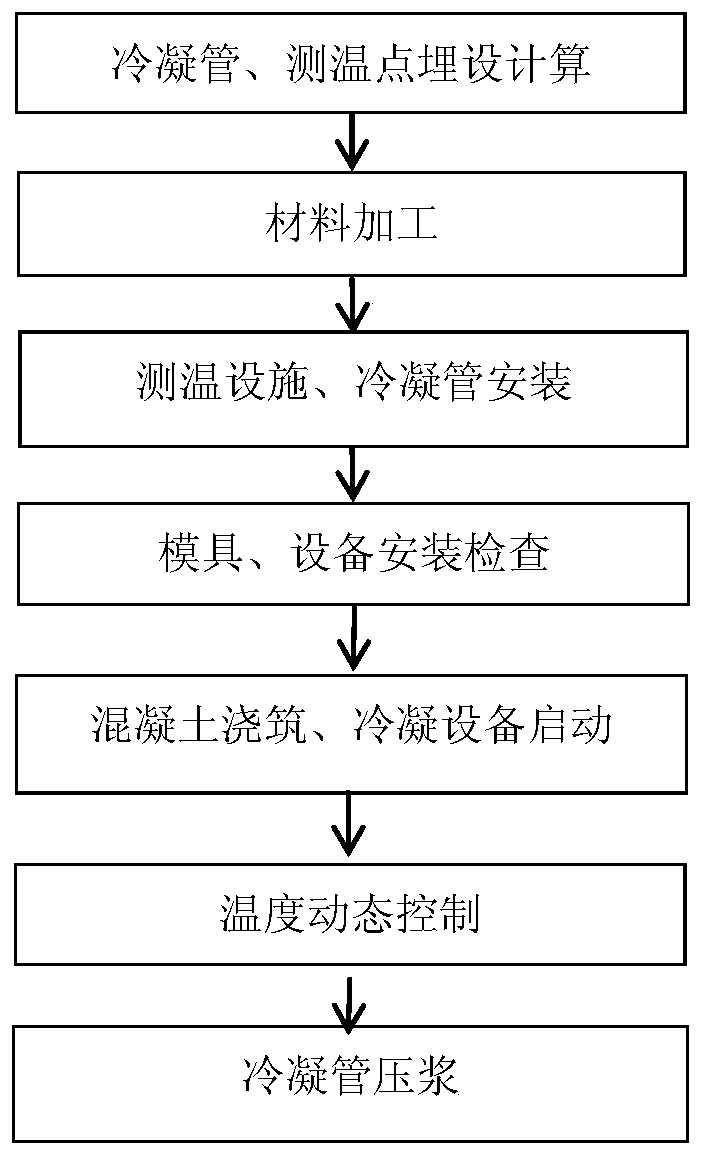

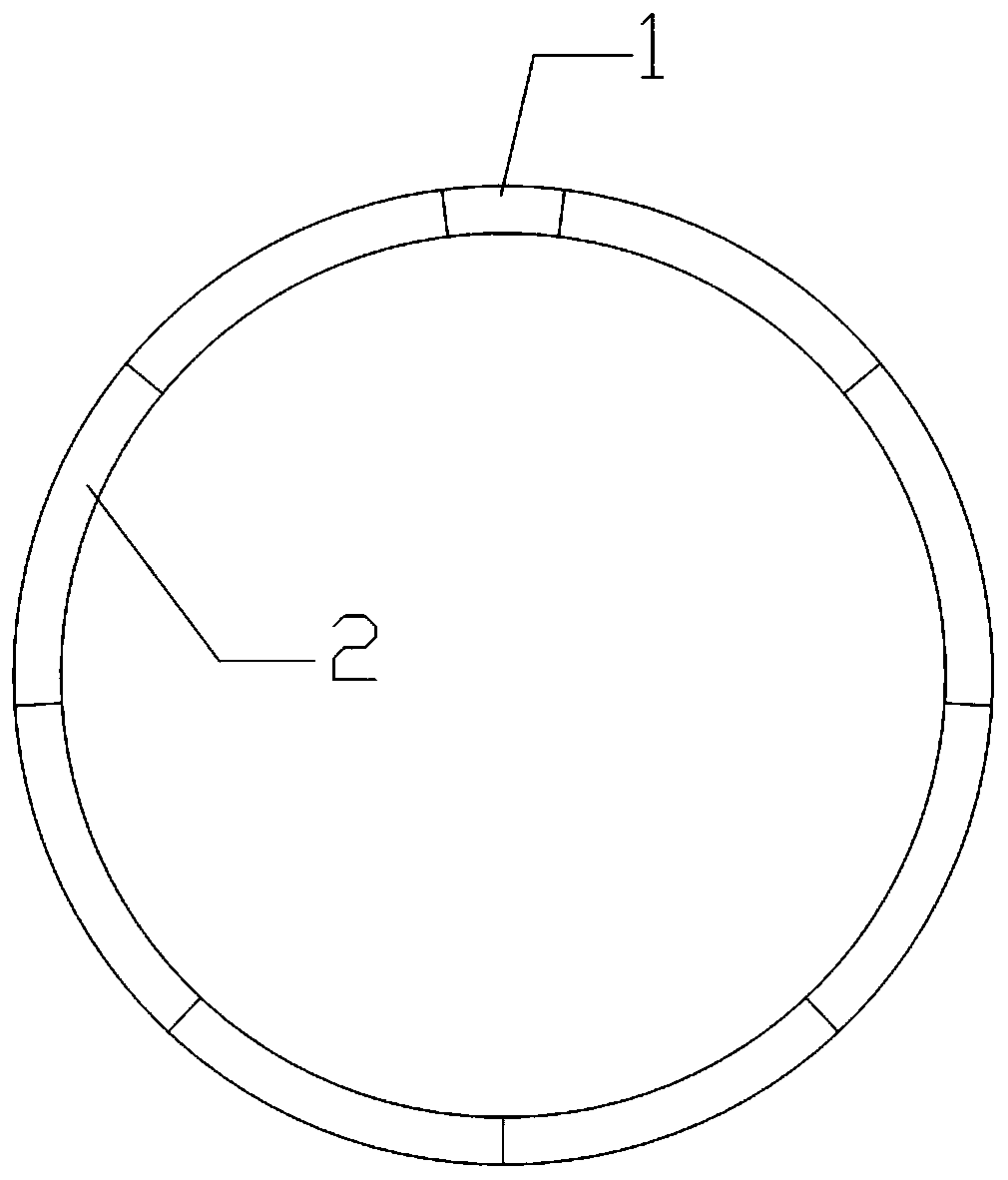

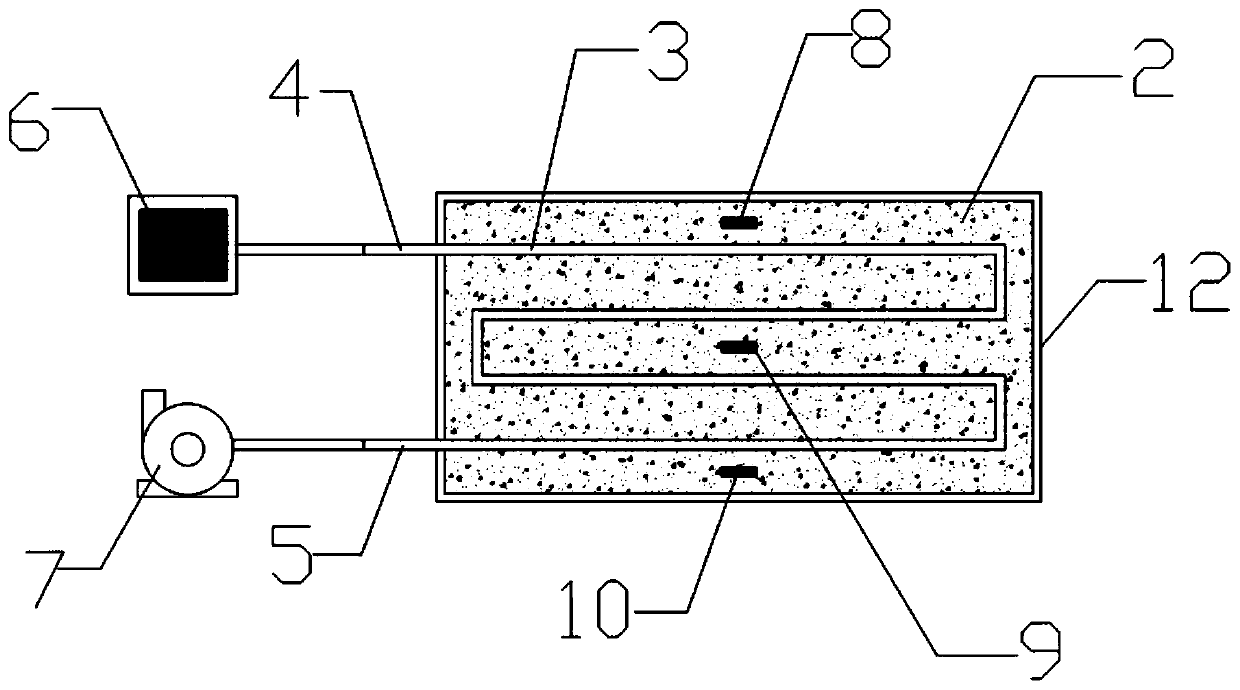

[0033] refer to Figure 1 to Figure 8 , an air-cooled large-diameter shield segment condensing tube device, the device includes a condensing tube 2 embedded in the shield segment and the first, second, and third temperature sensors for detecting the temperature of concrete; Air inlet 4 and air outlet 5 are respectively provided at the head and tail of the condensing pipe assembly; the air inlet 4 is connected to the water-cooled air conditioner 6;

[0034] Further, the first temperature sensor 9 is set at the middle of the shield segment, the second temperature sensor 8 is set at the side of the shield segment close to the water inlet, and the third temperature sensor 10 is set at the The shield segment is on the side of the water outlet.

[0035] Still further, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com