A use of sio 2 Method for preparing nonpolar a-plane gan epitaxial layer as substrate

An epitaxial layer, non-polar technology, applied in the field of semiconductor material preparation, can solve the problem of high cost of non-polar GaN

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

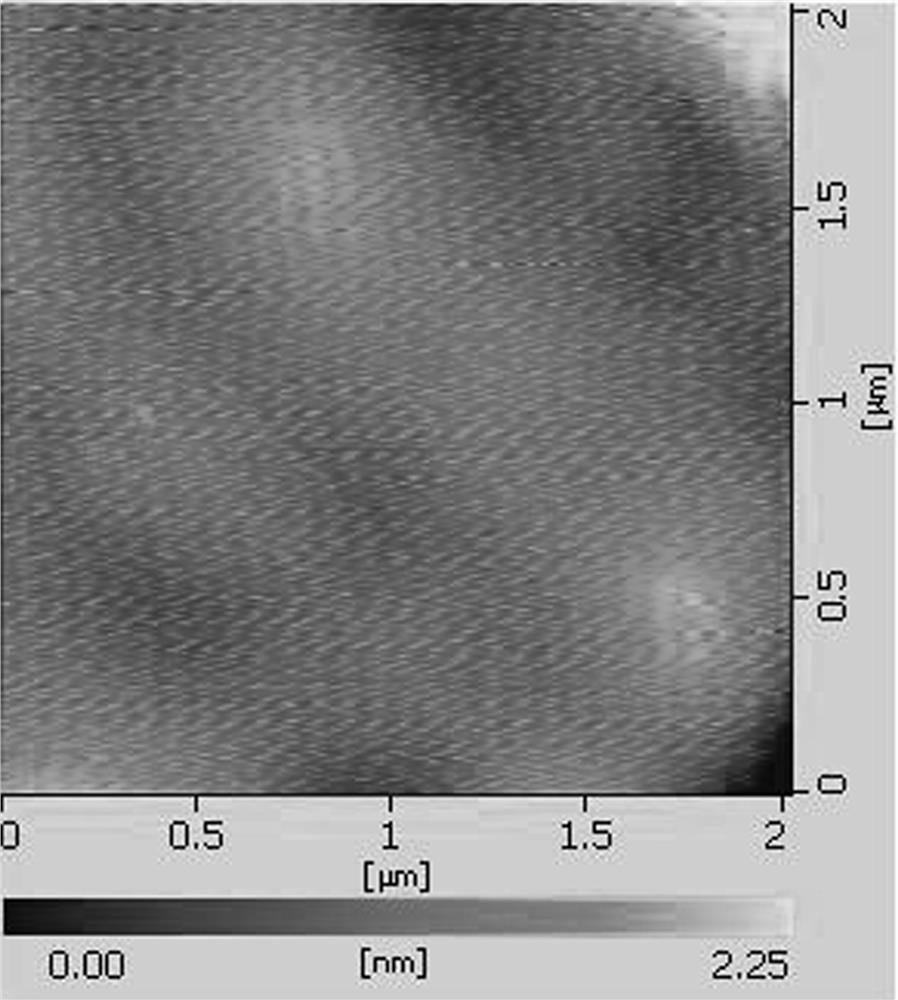

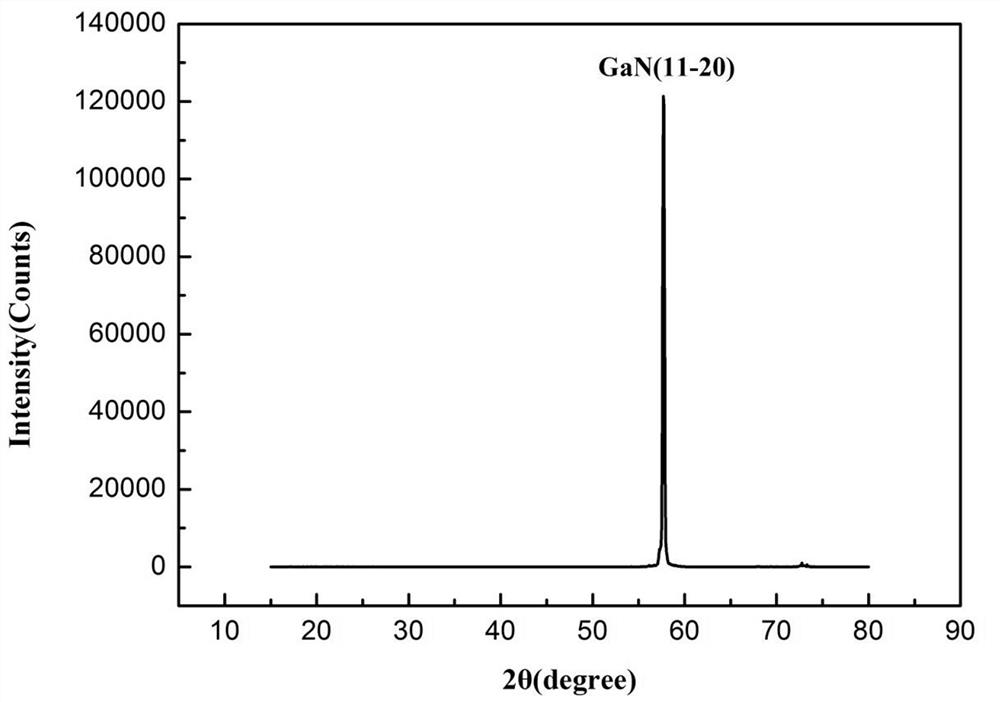

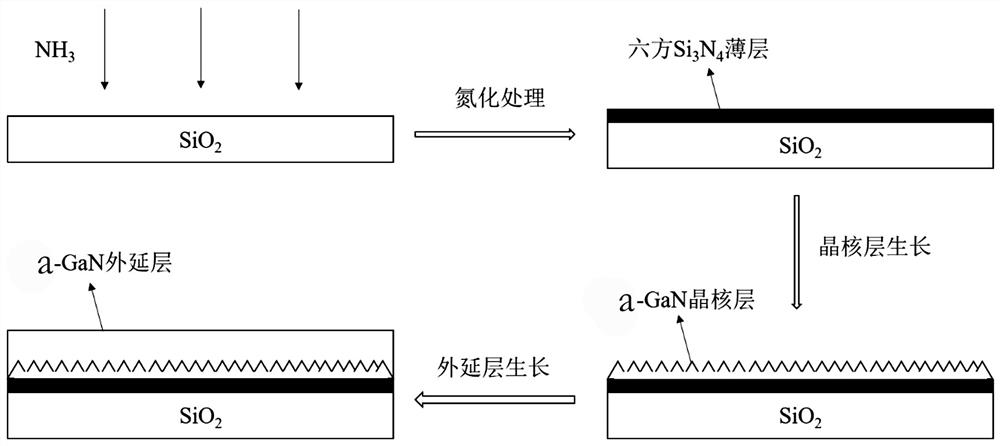

[0018] Embodiment 1: a kind of SiO 2 As a method for preparing a non-polar a-plane GaN epitaxial layer as a substrate, the SiO 2 The substrate is nitrided at a high temperature of 1200-1300°C and a large ammonia gas flow rate of 4000-4500 sccm. After the treatment, SiO 2 a-Si with close-packed hexagonal structure formed on the substrate surface 3 N 4 Thin layer; a-plane oriented GaN crystal nucleus layer is grown on the thin layer, and finally a-plane GaN epitaxial layer is grown on the basis of non-polar crystal nucleus.

[0019] Specific steps are as follows:

[0020] (1) SiO 2 Substrate surface clean, nitriding treatment: SiO 2 The substrate was placed in a metal-organic vapor deposition (MOCVD) reaction chamber, and the substrate was cleaned at a temperature of 1250 °C under a hydrogen atmosphere; Pressure 150 mbar; SiO after nitriding 2 A layer of a-Si with hexagonal close-packed structure will be formed on the surface of the substrate. 3 N 4 Thin layer with a th...

Embodiment 2

[0024] Embodiment 2: a kind of in SiO 2 The method for preparing a nonpolar a-plane GaN epitaxial layer from a substrate, the specific steps are as follows:

[0025] (1) SiO 2 Substrate surface clean, nitriding treatment: SiO 2 The substrate was placed in a metal-organic vapor deposition (MOCVD) reaction chamber, and the substrate was cleaned at a temperature of 1300 ° C under a hydrogen atmosphere; The chamber pressure is 200 mbar; after nitriding SiO 2 A layer of a-Si with hexagonal close-packed structure will be formed on the surface of the substrate. 3 N 4 Thin layer with a thickness of 10nm;

[0026] (2) Growth of a-plane GaN crystal nucleus layer: after step (1), lower the temperature to 1050 °C, feed 50 sccm gallium source and 400 sccm ammonia gas into the reaction chamber, the V / III ratio is 200, and the reaction pressure Grow for 35 s under the condition of 200 mbar to generate a-plane GaN crystal nucleus layer;

[0027] (3) Growth of a-plane GaN epitaxial layer:...

Embodiment 3

[0028] Embodiment 3: a kind of in SiO 2 The method for preparing a nonpolar a-plane GaN epitaxial layer from a substrate, the specific steps are as follows:

[0029] (1) SiO 2 Substrate surface clean, nitriding treatment: SiO 2 The substrate was placed in a metal-organic vapor deposition (MOCVD) reaction chamber, and the substrate was cleaned at a temperature of 1200 °C under a hydrogen atmosphere; The chamber pressure is 100 mbar; after nitriding SiO 2 A layer of a-Si with hexagonal close-packed structure will be formed on the surface of the substrate. 3 N 4 Thin layer with a thickness of 6nm;

[0030] (2) Growth of a-plane GaN crystal nucleus layer: after step (1), lower the temperature to 1100 °C, feed 45 sccm gallium source and 300 sccm ammonia gas into the reaction chamber, keep the V / III ratio at 150, and keep the pressure at Grow for 45 s under the condition of 100 mbar to generate a-plane GaN crystal nucleus layer;

[0031] (3) Growth of a-plane GaN epitaxial la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com