Constant Temperature Crystal Oscillator Aging Automatic Test System

A constant temperature crystal oscillation and automatic test system technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of difficult test system transformation, increased test cost, and high temperature in the test room, so as to improve test ability and work efficiency, reduce The effect of test cost and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention is further explained below in connection with the embodiments, and the object is merely understood, and therefore, the specific embodiments are not limited to the scope of the invention.

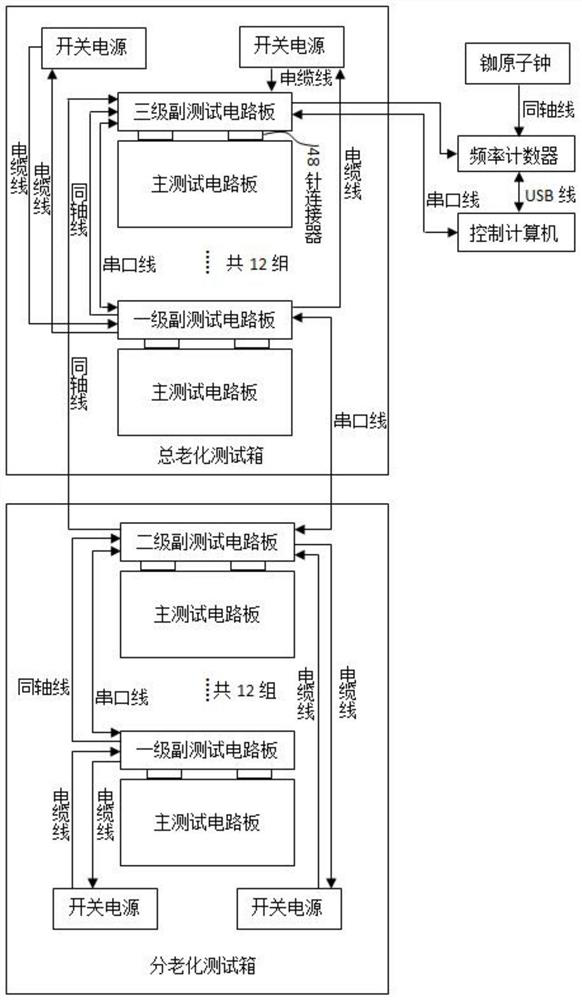

[0038]Seefigure 1 The constant temperature crystal oscillator aging test system of the present invention includes: a total aging test box, multiple division of aging test box, control computer, switching power supply, frequency counter, and 铷 atom clock, the total aging test box includes 12 main test circuit boards, 1 three-level sub-test circuit board, 11 piece secondary sub-circuit test board, the interior of the split aging test box included 12 primary test circuit boards, 1 second secondary subtraction circuit board, 11 sets of secondary circuit test boards.铷 The atomic clock output signal is connected to the frequency counter external frequency standard input interface via the coaxial line, providing an external frequency standard for the counter, allowing the counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com