A three-dimensional graded gangue and gas blocking device and method for self-forming roadways without coal pillars

A coal pillar-free, road-forming technology, used in mining equipment, earth-moving drilling, surface mining, etc., can solve the problems of harmful gas gushing out, unable to be recycled again, pressed into the bottom plate, etc., to avoid gas influx, avoid Unfavorable deformation, the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

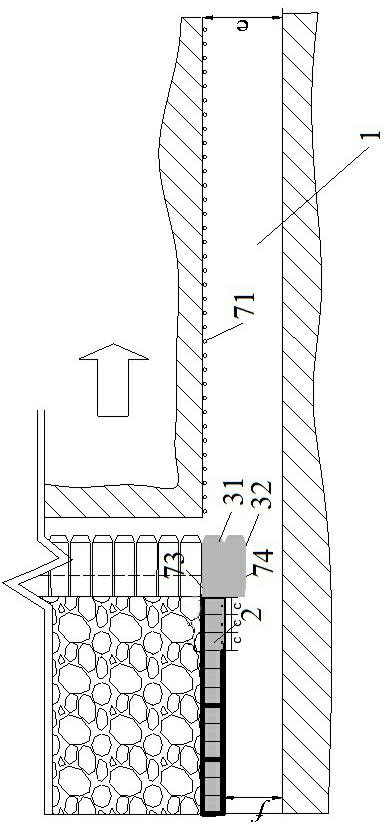

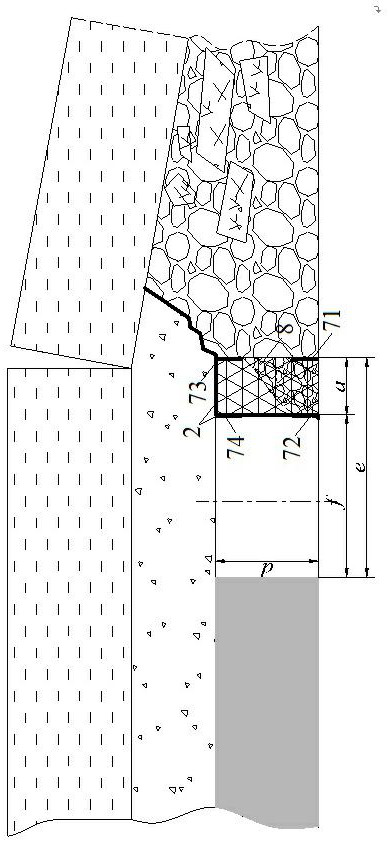

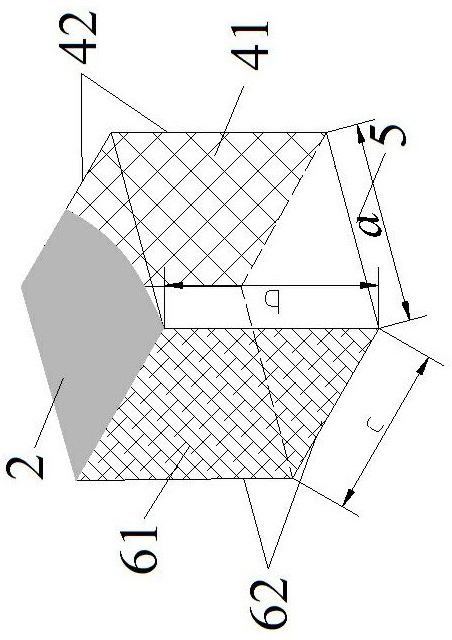

[0038] Such as Figure 1-6shows a three-dimensional graded gangue-blocking gas-blocking device for self-forming lanes without coal pillars, including gas-blocking materials 2 and graded gangue-blocking units connected in sequence; the graded gangue-blocking unit includes a mesh-shaped primary gangue-blocking mechanism 4 and Mesh secondary gangue retaining mechanism 6, the mesh of the first grade gangue retaining mechanism 4 is larger than the mesh of the second grade gangue retaining mechanism 6, the first grade gangue retaining mechanism is located in the goaf close to the falling gangue, and the second grade gangue retaining mechanism is located One side of the roadway; the upper and lower ends of the first-level gangue-blocking mechanism 4 and the second-level gangue-blocking mechanism 6 are connected through a horizontal hydraulic device 5, and the horizontal hydraulic device 5 realizes lateral expansion and contraction through hydraulic pressure, thereby realizing the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com