Flame-retardant visible light curing digital jet printing white ink for three-dimensional decorative pictures

A digital jet printing and visible light technology, applied in the field of decorative painting inks, can solve the problems of radiation hazards of UV radiation sources, short wavelengths of UV radiation sources, and easy chalking of the bottom layer, so as to achieve broad market application prospects and improve curing depth Shallow, the effect of meeting the requirements of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

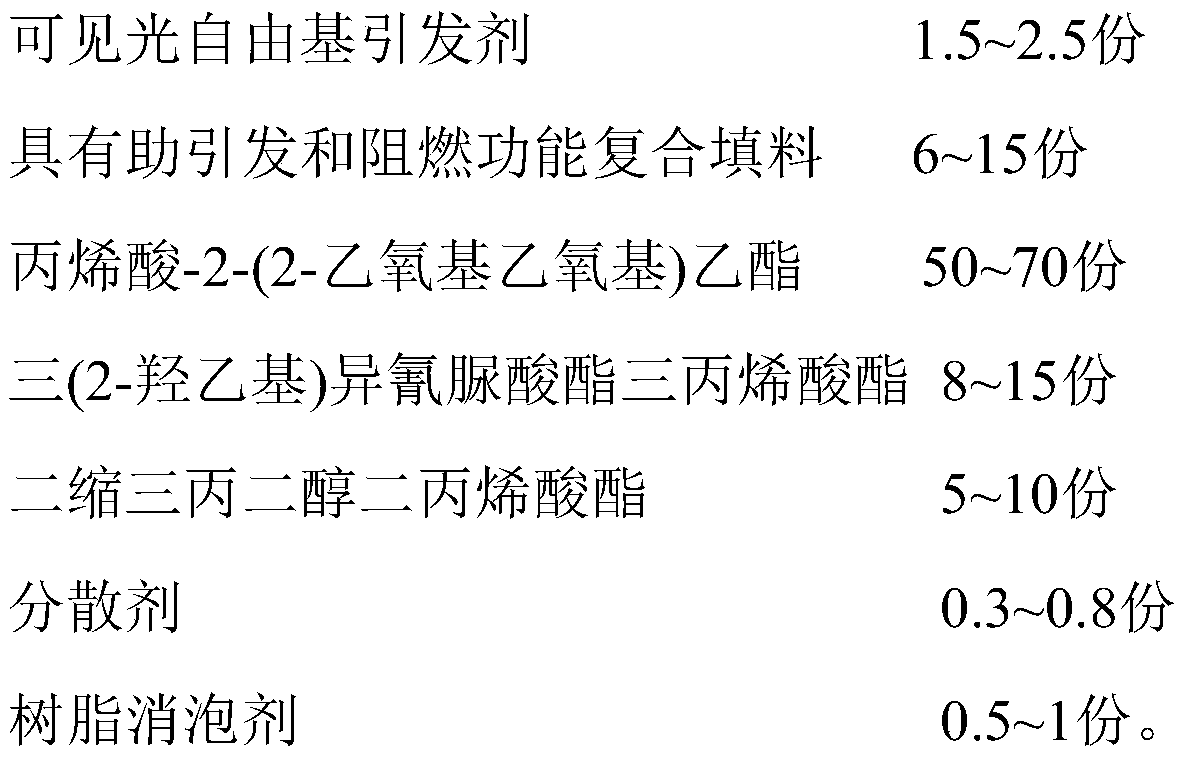

[0023] A flame-retardant visible light curing digital jet printing white ink for three-dimensional decorative painting, the composition and content of which are:

[0024]

[0025] The light-curing flame-retardant digital jet printing white ink prepared according to the above-mentioned component dosage can use a blue light source with a wavelength of 450nm and a power of 200W as the radiation source.

Embodiment 2

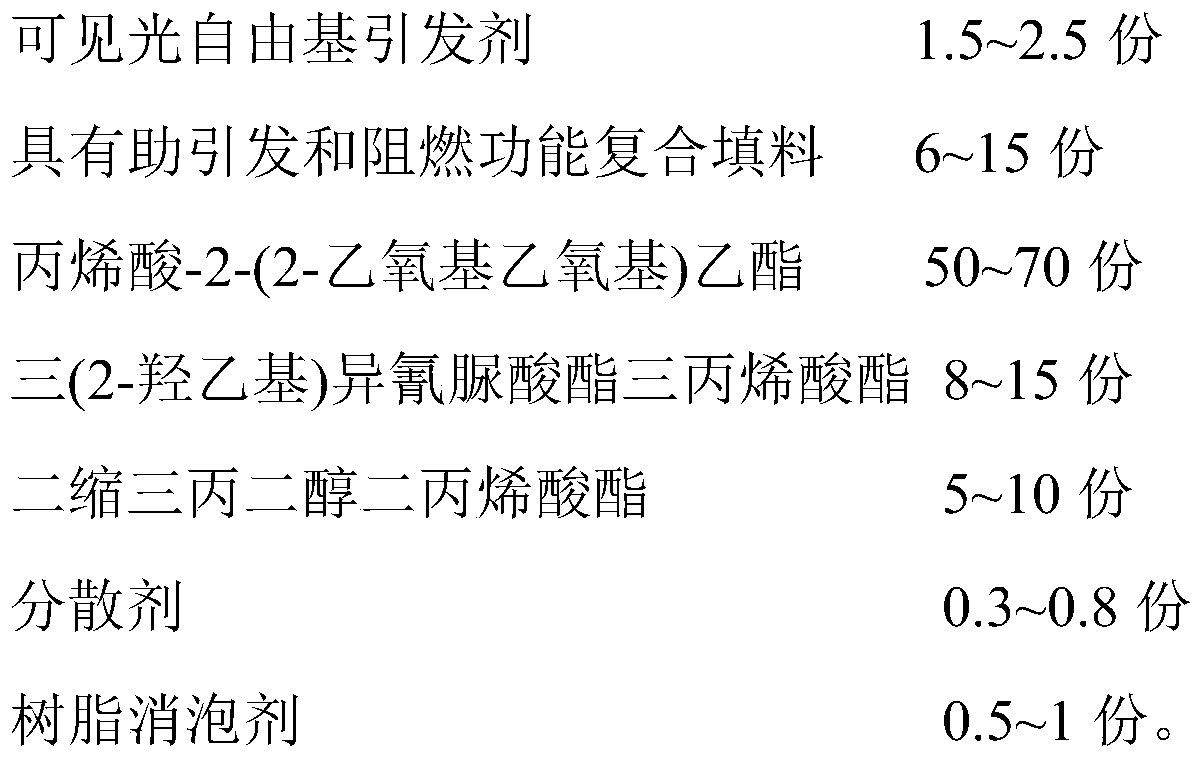

[0027] A flame-retardant visible light curing digital jet printing white ink for three-dimensional decorative painting, the composition and content of which are:

[0028]

[0029] The light-curing flame-retardant digital jet printing white ink prepared according to the above-mentioned dosage of components can use a green light source with a wavelength of 500-520nm and a power of 500W as the irradiation light source.

Embodiment 3

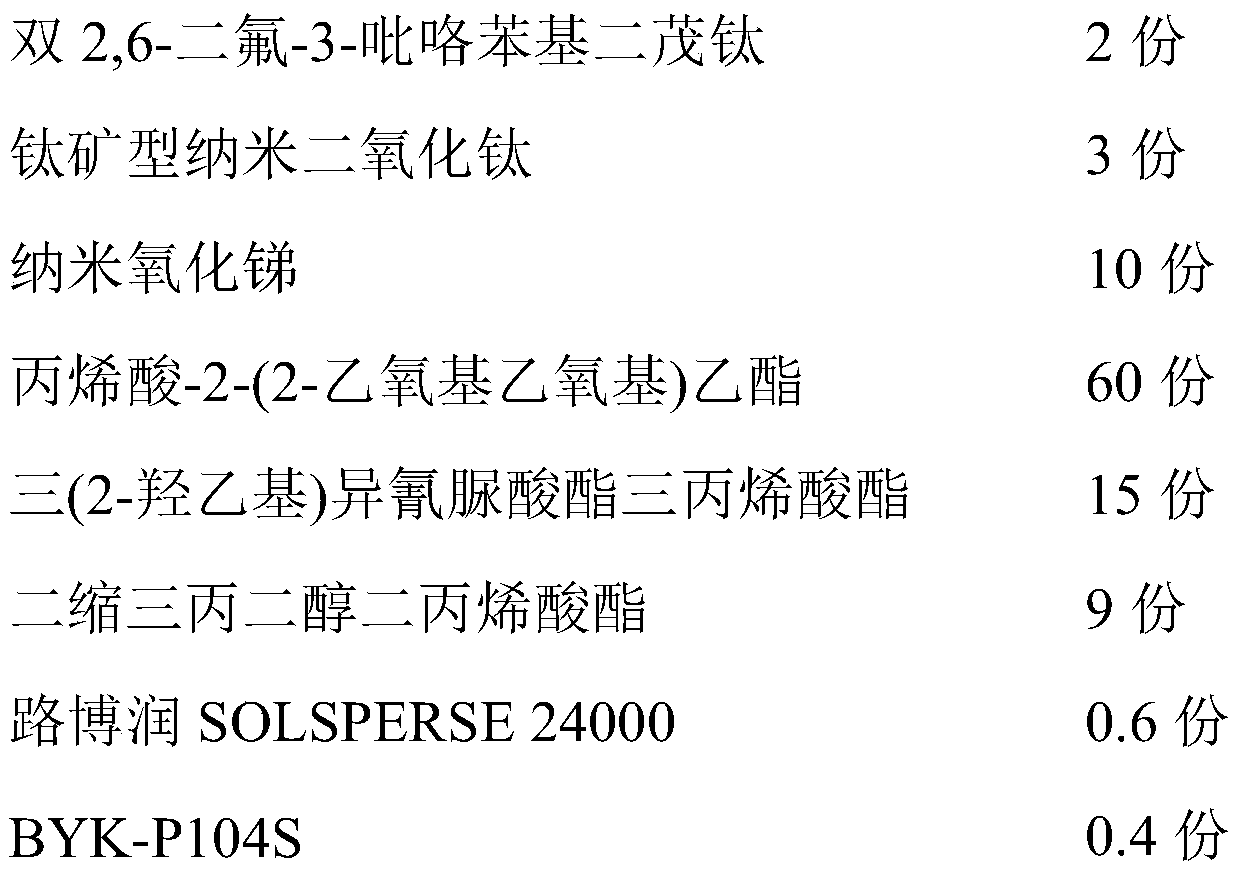

[0031] A flame-retardant visible light curing digital jet printing white ink for three-dimensional decorative painting, the composition and content of which are:

[0032]

[0033] The light-curing flame-retardant digital jet printing white ink prepared according to the above-mentioned dosage of components can use a blue light source with a wavelength of 450-470nm and a power of 150W as the irradiation light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com