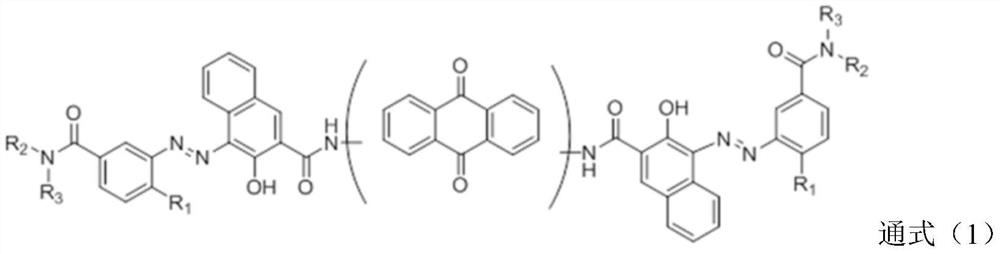

Azo pigment, color filter, colorant and coloring composition used therefor, and display device and imaging element including the same

A technology of color filter and coloring composition, which is applied in azo dyes, optical elements, anthraquinone-azo dyes, etc., can solve the problems of high tinting strength, achieve excellent fastness, good storage stability, coating The effect of less membrane foreign matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0422] (Production of Azo Pigment 1)

[0423] [hua 20]

[0424]

[0425] After adding 185 parts of base compound [B-1] to 1500 parts of N-methylpyrrolidone, 294 parts of 35% hydrochloric acid was added, and it cooled so that it might become -2 degreeC - 0 degreeC. After adding 208 parts of 25% sodium nitrite aqueous solution to the said solution, it stirred for 30 minutes, maintaining at 0 degreeC - 5 degreeC, and prepared the diazonium solution. Separately, a coupling solution containing 216 parts of the coupling compound [C-1], 316 parts of a 25% sodium hydroxide solution, and 1500 parts of methanol was prepared. The prepared diazonium solution and the coupling solution were added dropwise to 1000 parts of an acetic acid buffer solution having a pH value of 5.4 over 10 minutes. After completion of the dropwise addition, the mixture was stirred at room temperature for 30 minutes, and further stirred while maintaining the temperature at 80°C. The precipitated product was ...

Embodiment 2

[0430] (Production of Azo Pigment 2)

[0431] Except having used 169 parts of base compounds [B-2] instead of 185 parts of base compounds [B-1] used in the manufacture of azo pigments 1, the same operations as in manufacture of azo pigments 1 were performed to obtain 400 parts (Yield: 97.5%) Azo Pigment 2. Mass analysis and elemental analysis were performed by TOF-MS, and the result was identified as azo pigment 2.

[0432] [Chemical 22]

[0433] Azo Pigment 2

[0434]

Embodiment 3

[0436] (Production of Azo Pigment 3)

[0437] Except having used 210 parts of base compound [B-3] instead of 185 parts of base compound [B-1] used in manufacture of azo pigment 1, the same operation as that of manufacture of azo pigment 1 was performed to obtain 420 parts (Yield: 96.5%) Azo Pigment 3. Mass analysis and elemental analysis were carried out by TOF-MS, and the result was identified as azo pigment 3.

[0438] [Chemical 23]

[0439] Azo Pigment 3

[0440]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com