Sulfonated PVDF-based IPMC electric actuator, preparation method thereof and application of sulfonated PVDF-based IPMC electric actuator in VR touch gloves

An electric actuator and sulfonation technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc. Low efficiency and other problems, to achieve the effect of high mechanical properties, low energy consumption, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (preparation of sulfonated PVDF powder)

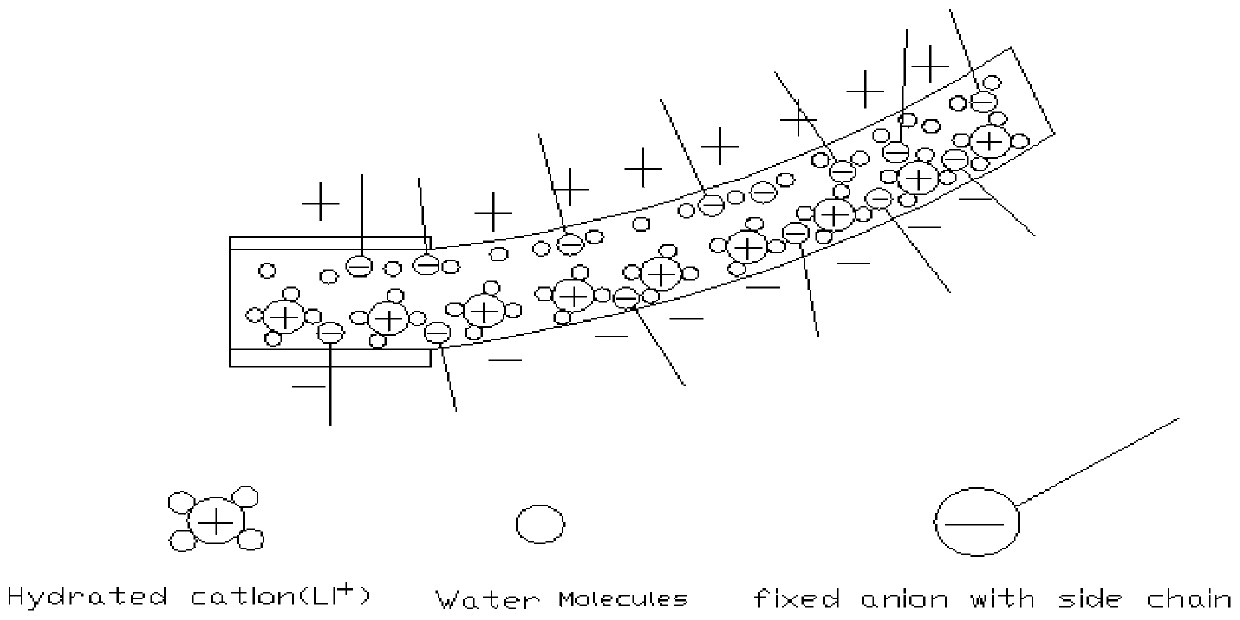

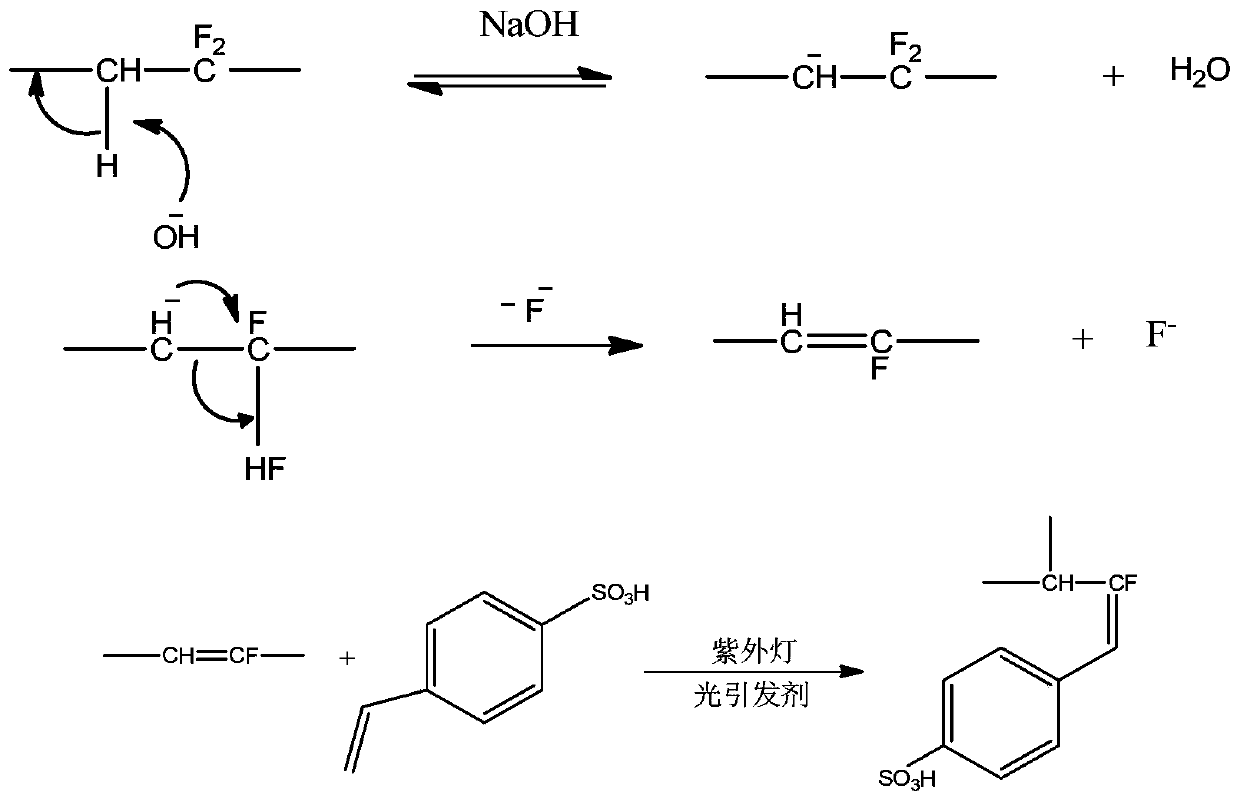

[0036] Preparation of sulfonic acid grafted PVDF powder: Weigh 3g of PVDF solid powder, soak in 0.07mol / L NaOH aqueous solution for 2h, and then soak in deionized water for 2h. Add 10mL of photoinitiator 2-hydroxyl-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone and sodium p-vinylbenzenesulfonate solution, and place it under a UV lamp Initiate and irradiate for 15h, 24h, 36h, 45h, 50h, 60h respectively to obtain sulfonated PVDF solid powder. Such as figure 2 Shown is the grafting mechanism diagram of sulfonated PVDF solid powder.

[0037] In order to judge the influence of UV irradiation time on the performance of IPMC, the IPMC prepared with different irradiation times was placed on the two poles of the power supply, the control voltage was 3V, the working frequency was 0.5Hz, and the length, width, and thickness were fixed at 30, 3, and 0.11, respectively. mm, use a high-speed camera (Olympus) and a laser d...

Embodiment 2

[0040] Embodiment 2 (electrospinning prepares sulfonated PVDF electrolyte membrane)

[0041] Preparation of sulfonic acid grafted PVDF composite basement membrane by electrospinning method:

[0042] (1) Preparation of sulfonated PVDF basement membrane solution: Weigh 1.2g sulfonated PVDF solid powder, add 15mL DMF solvent, heat and stir at 60°C, mix well, and then vacuumize to remove the bubbles in the solution to obtain sulfonic acid grafted PVDF Membrane solution;

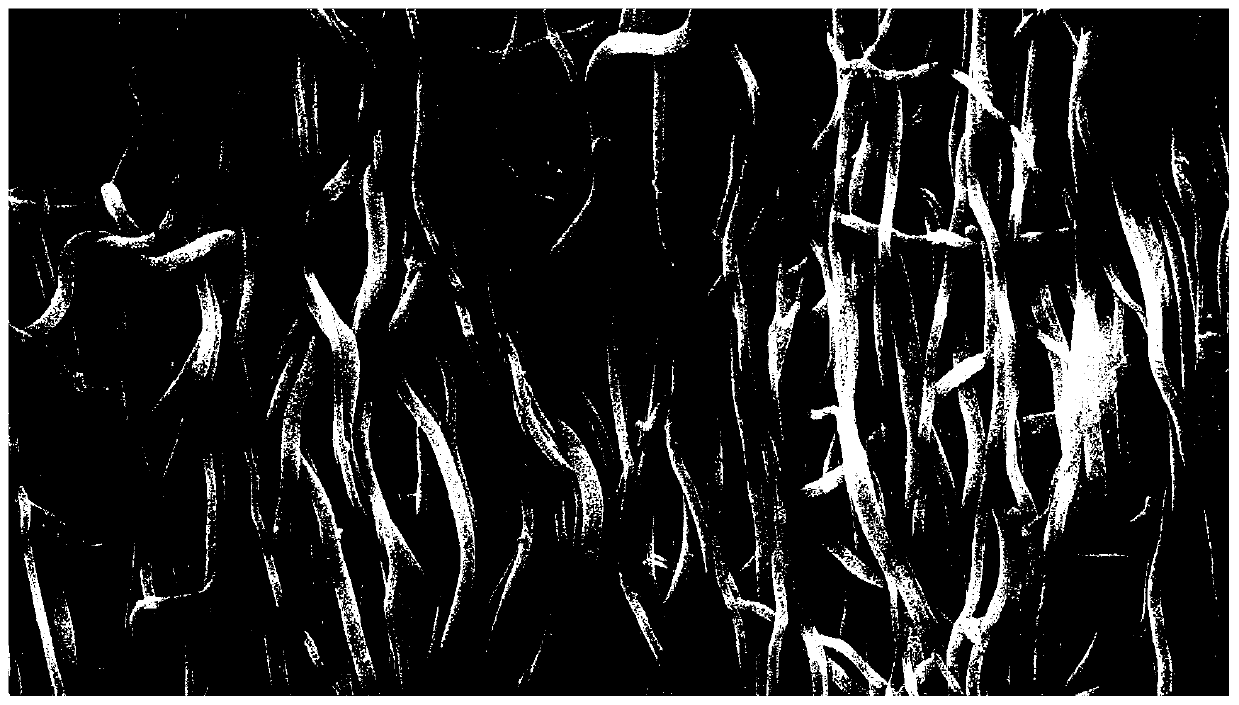

[0043] (2) Preparation of sulfonated PVDF electrolyte membrane: the membrane solution is placed on the syringe pusher, the high-voltage device line is connected, and the electrostatic shielding device is installed, the voltage is adjusted to 12kV, the distance between the needle tube and the receiving device roller is 20cm, and the The advancing speed was 0.20mL / h, and the spinning was performed for 24 hours to obtain the sulfonated PVDF basement membrane. A basement membrane of 1 cm×4 cm was cut out as IPMC. Su...

Embodiment 3

[0044] Embodiment 3 (preparation of PVDF / graphite electrode)

[0045] Preparation of PVDF / Graphite Electrode Liquid: Weigh conductive graphite powder and PVDF to adjust the mass ratio to 1.4:1 and put them in a beaker, add DMF and place them in an ultrasonic disperser to fully disperse evenly to obtain IPMC electrode liquid; / Graphite electrode solution is coated on a glass plate, and placed in an oven to dry to form a film; the sheet resistance of the electrode obtained by testing with a four-probe instrument is shown in Table 2.

[0046] Sheet resistance of table 2 electrode solution

[0047] 1 2 3 4 5 6 average Electrode solution resistance (Ω) 4.75 5.25 5.04 5.52 5.79 4.99 5.22

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com