Programmable 4D printing method with function of projecting with multiwavelength ultraviolet light

A multi-wavelength and wavelength technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of restricting 4D printing technology, slow printing speed, slow printing speed, etc., and achieve convenient and efficient sample printing process , Improve printing efficiency, reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

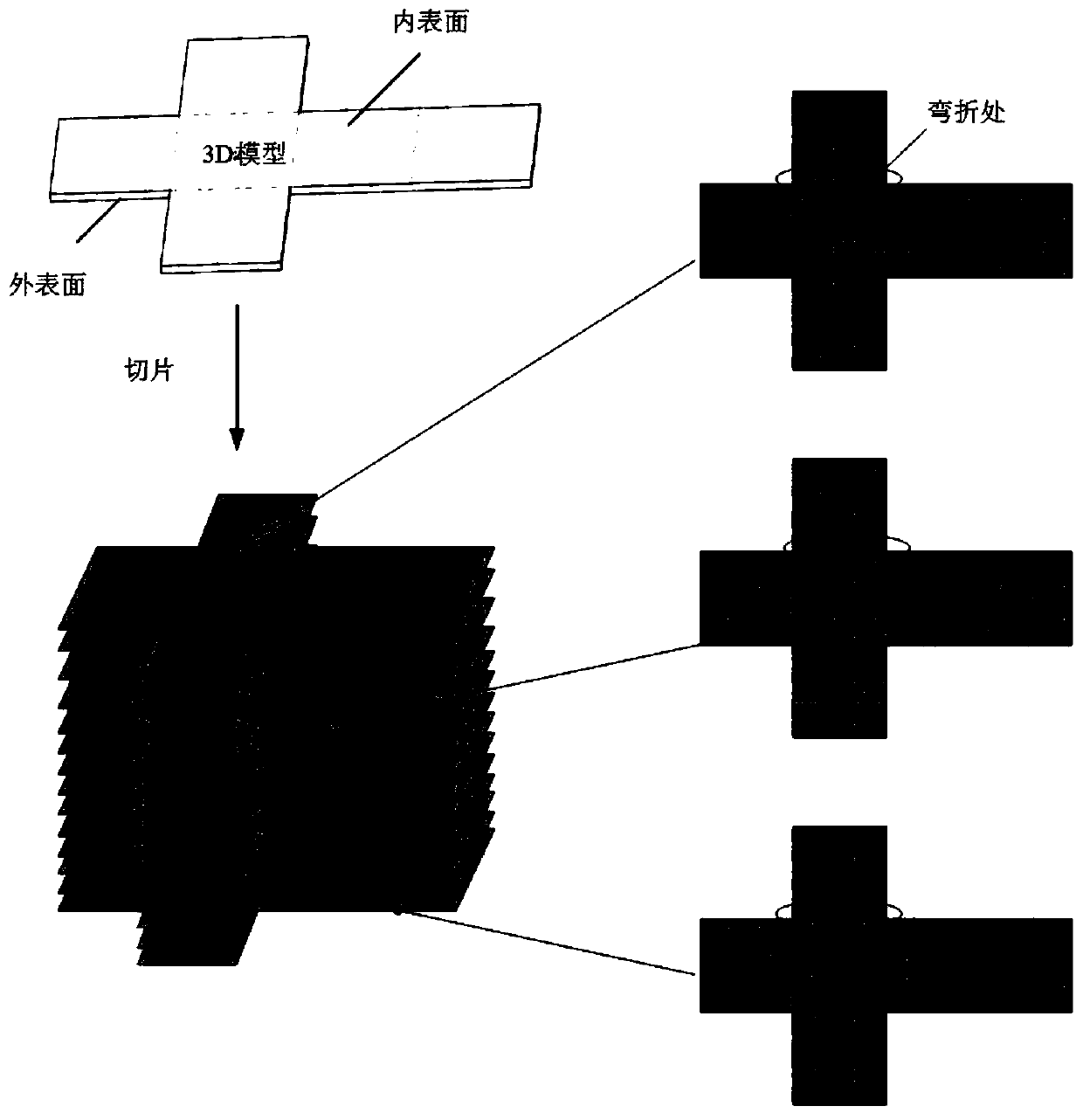

[0031] A programmable 4D printing method utilizing multi-wavelength ultraviolet projection of the present invention comprises the following steps:

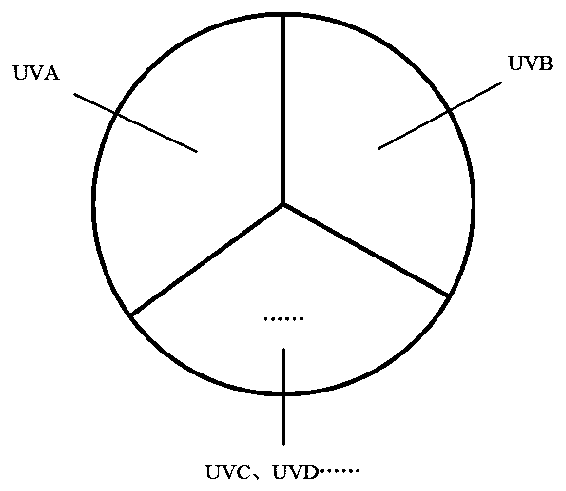

[0032] 1. Selection of printing materials: According to the functional design of the printed product, select a suitable photosensitive material, which has the following characteristics: First, the material can obtain different properties after being cured by different wavelengths of ultraviolet rays. Differences in mechanical properties, thermal properties, or electromagnetic properties occur after wavelength ultraviolet radiation; secondly, after the material is printed into a sample, it can respond to specific external stimuli, for example, the material is first printed into a planar structure, the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com