One-hand opening knife processing device based on laser cutting technology

A processing device and laser cutting technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of long time-consuming clamping and loosening of workpieces to be processed, so as to save the manual grinding process and increase work. Efficiency, the effect of smooth processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

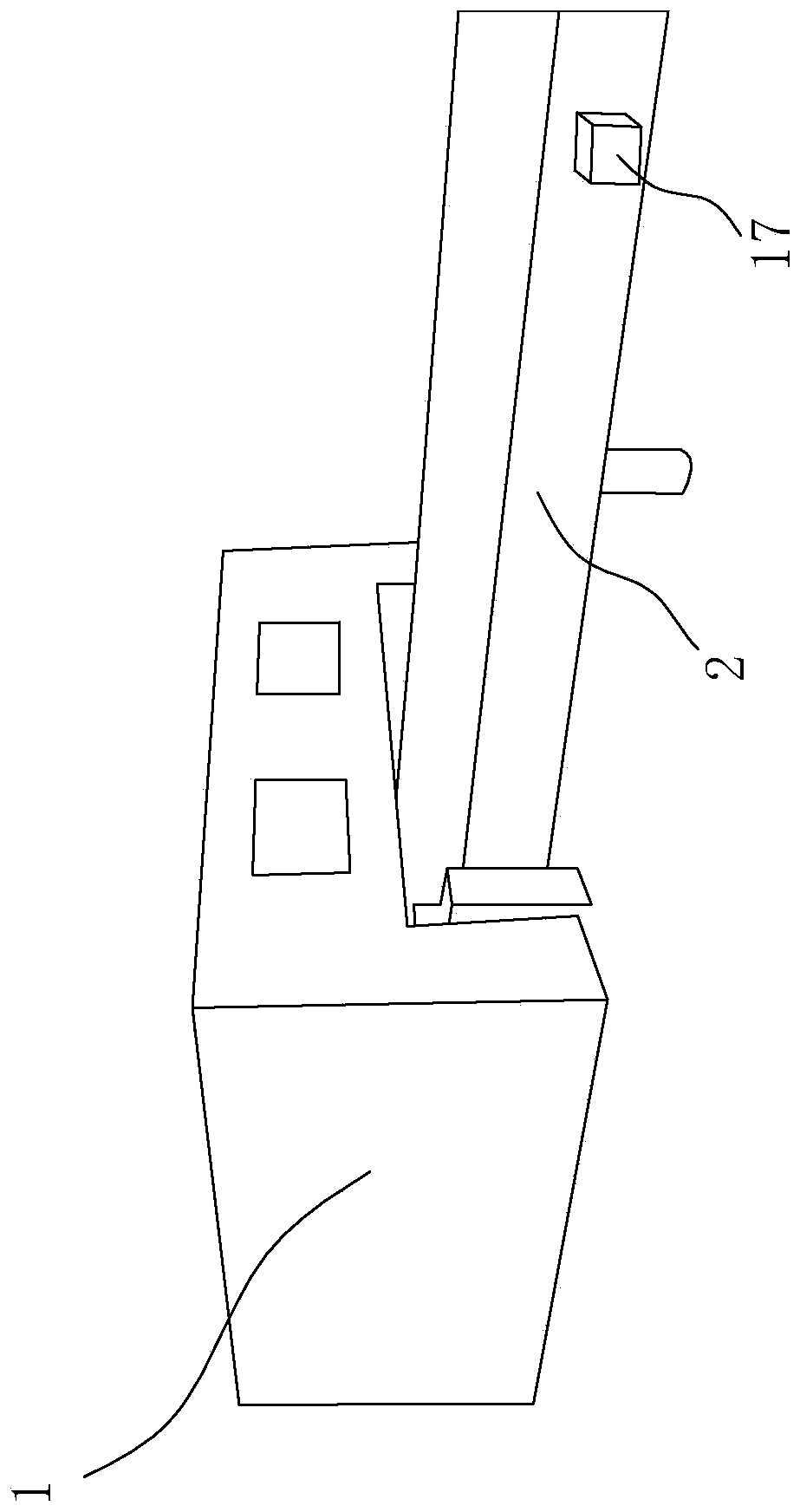

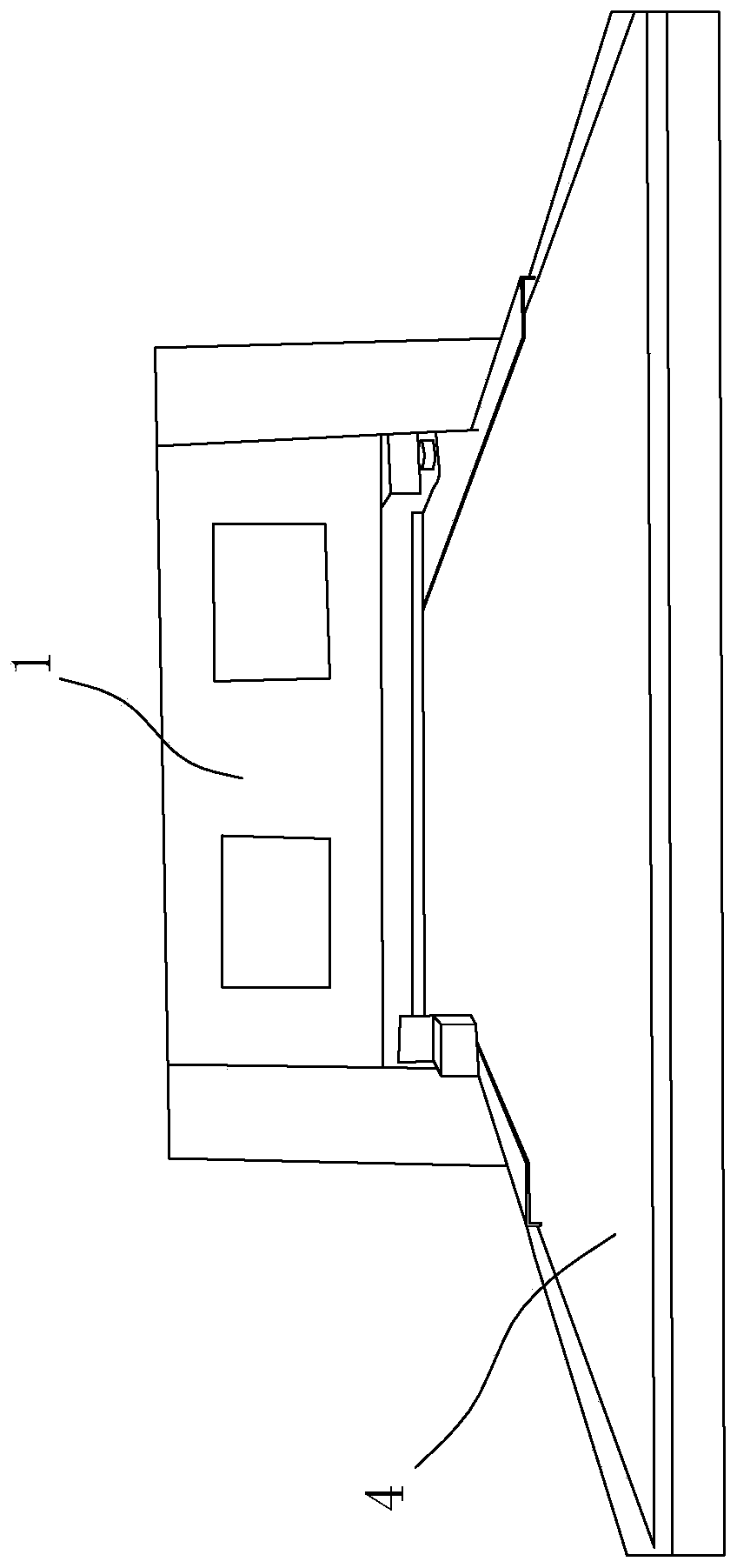

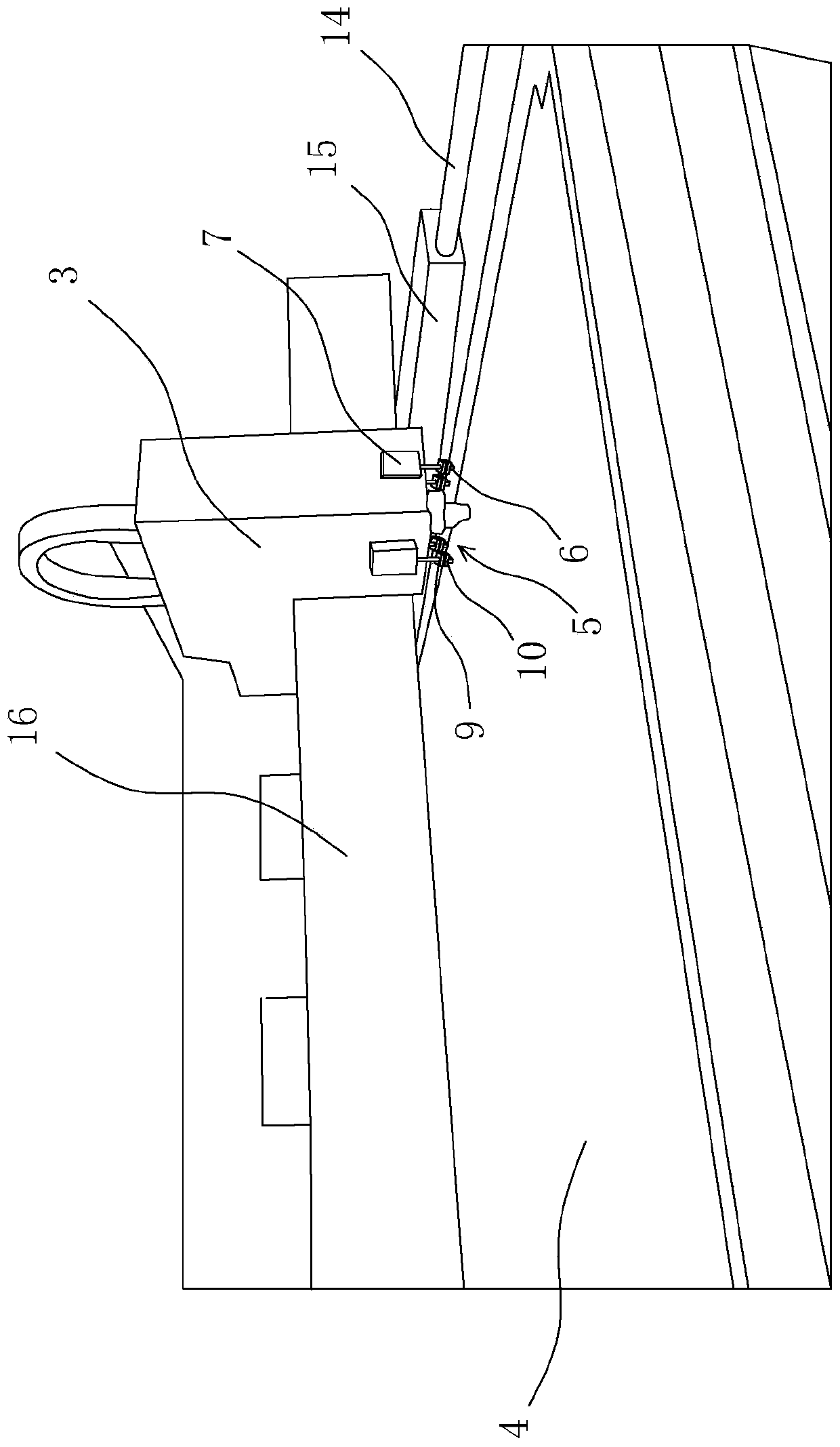

[0023] Such as Figure 1-Figure 3 As shown, a single-opening processing device based on laser cutting technology includes a casing 1 and a lathe 2 inserted into the casing 1. The lathe 2 is provided with a conveyor belt 4 that can move in a circumferential direction. Inside the casing 1 A laser cutting head 3 located above the conveyor belt 4 and capable of reciprocating linear motion along the X-axis and Y-axis is provided. The laser cutting head 3 is also provided with several movable fixing components 5 for fixing the products to be cut.

[0024] In this embodiment, the conveyor belt 4 that can move in the circumferential direction on the lathe 2 can transfer the workpiece to be processed into the housing 1, which can increase work efficiency, and the laser cutting head 3 that can reciprocate linearly along the X-axis and Y-axis can quickly Cutting the workpiece to be processed into the target product can increase work efficiency, and the processed surface after cutting is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com