Waste removing device

一种清理装置、废料的技术,应用在辅助装置、激光焊接设备、辅助焊接设备等方向,能够解决影响下一工件加工质量、不方便清理废料等问题,达到降低温度、结构简单、加工效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

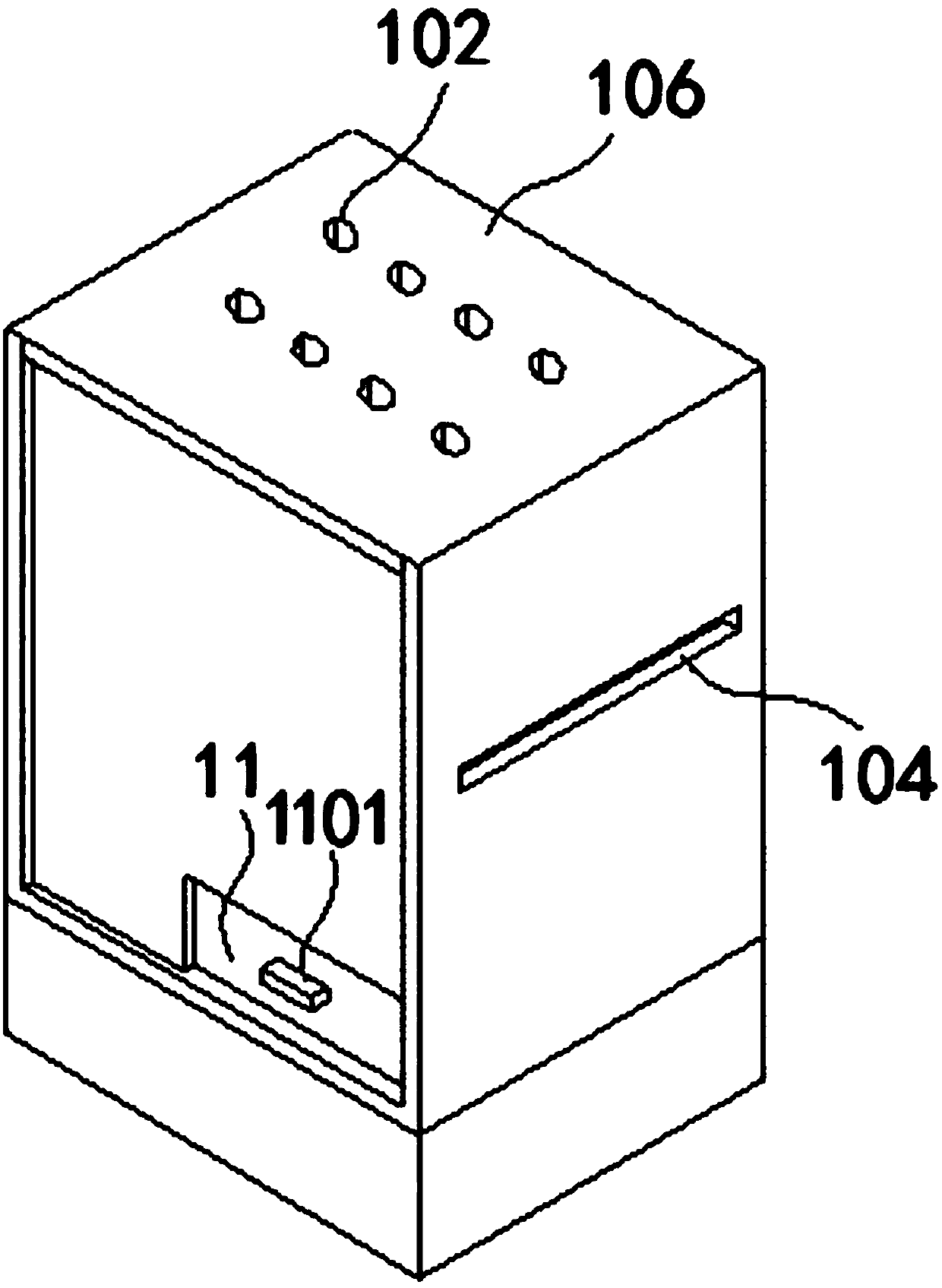

[0026] Such as figure 1 , figure 2 , image 3 As shown, the waste cleaning device for laser cutting equipment of the present invention includes:

[0027] A protective box 1, the protective box 1 is installed on the bracket, the top of the protective box 1 is provided with a sliding device 101, the inner side wall of the protective box 1 is provided with a long groove 104, the protective box A notch 105 is formed on the front side wall of the body 1 . The upper cover of the protective box 1 is provided with several air inlet holes 102 , and the side wall of the protective box 1 is provided with several air outlet holes 103 . The upper cover 106 of the protective box 1 is a reversible structure, and the upper cover 106 is hinged on an inner side wall of the protective box 1 through a second hinge 107 .

[0028] Processing platform 2, the processing platform 2 is arranged in the protective box 1, one side of the processing platform 2 is hinged on the inner side wall of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com