High-efficiency and energy-saving mixing device

A mixing device, high-efficiency and energy-saving technology, applied in mixers, mixers with rotating containers, transportation and packaging, etc., can solve problems such as energy waste, and achieve the effects of reducing noise pollution, saving resources, and good market promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

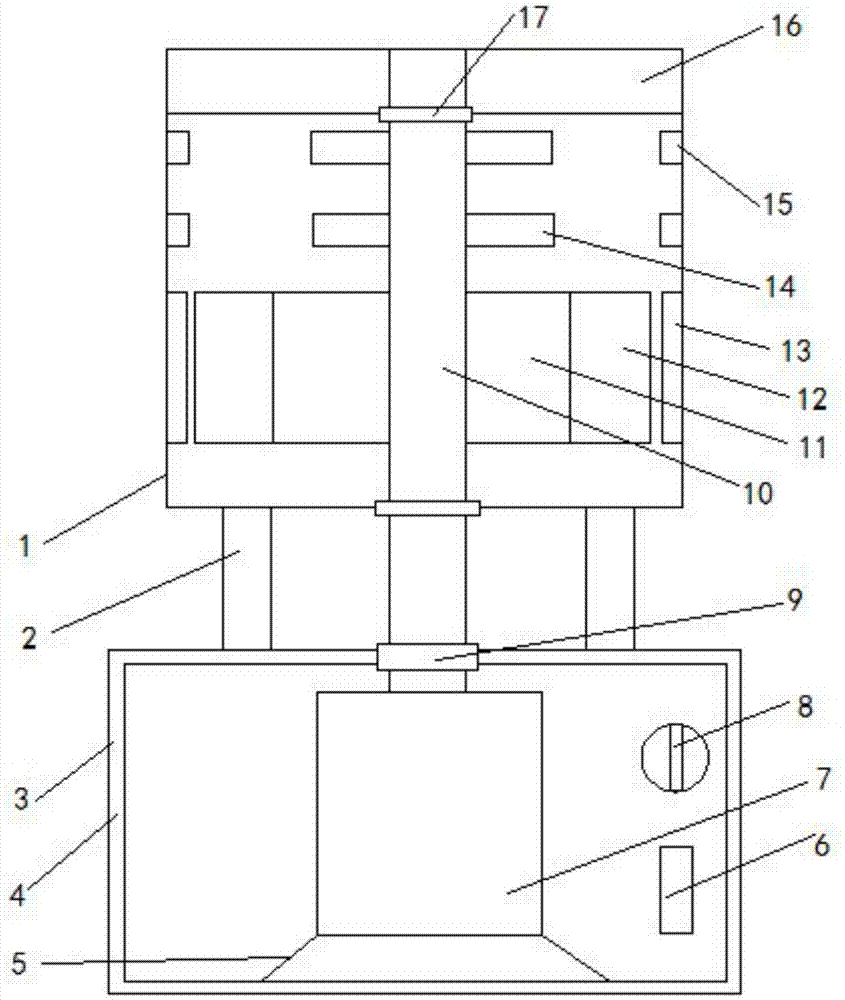

[0031] The high-efficiency and energy-saving mixing device includes: mixing tank 1, support frame 2, motor storage box 3, soundproof sponge 4, motor base 5, switch 6, motor 7, emergency stop button 8, sealed bearing 9, motor shaft 10, center Gear 11, planetary gear 12, tooth profile 13, stirring blade 14, spoiler 15, sealing cover 16, sealing ring 17, motor storage box 3 is arranged on the bottom of the device, motor 7 is arranged inside the motor storage box 3, motor 7 Fixed on the motor base 5, the switch 6 and the emergency stop button 8 are arranged side by side on the right side of the motor storage box 3, the motor 7 is connected with the motor shaft 10, the stirring tank 1 is fixed on the support frame 2, and the support frame 2 is fixed on the motor On the storage box 3 , the central gear 11 is fixed on the motor shaft 10 , the stirring blade 14 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com