Hot-rolled section steel roll and its production method

A roll and section steel technology, which is applied in the direction of manufacturing tools, furnace types, heat treatment furnaces, etc., can solve the problems of non-collapse hot-rolled section steel rolls, reduce the tensile strength of the roll neck, and increase the probability of broken rolls, so as to improve the operation rate, The plastic deformation ability is obvious and the effect of reducing the number of turnings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention is described in detail below. The embodiments of the present invention are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described in detail with reference to the preferred embodiments, those skilled in the art should understand that the technical solutions of the invention can be modified or equivalently replaced , without departing from the spirit and scope of the technical solution of the present invention, all of which shall be covered by the claims of the present invention.

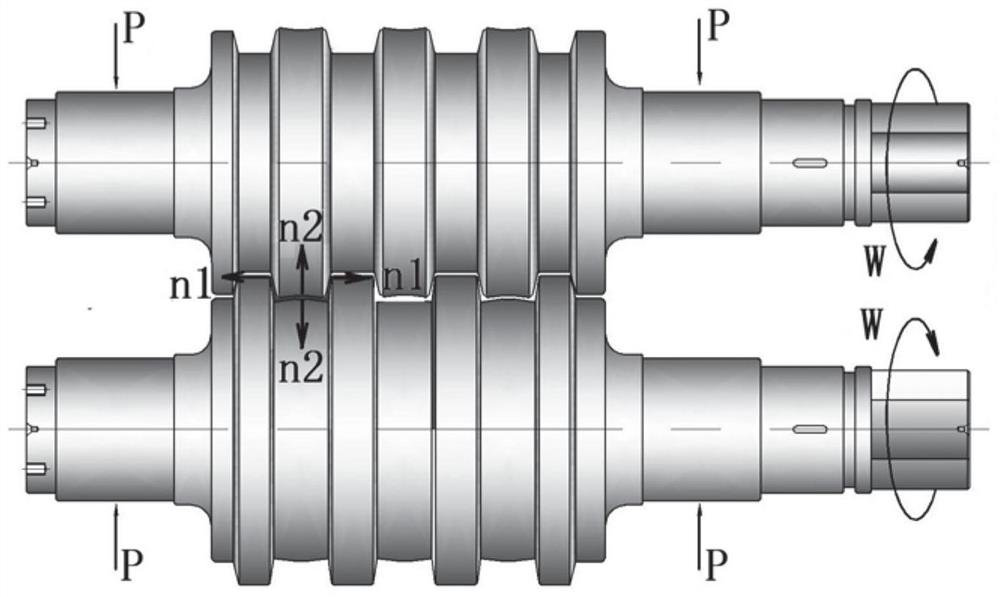

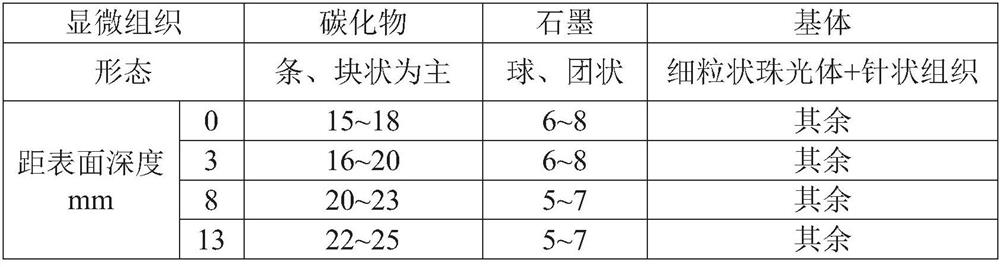

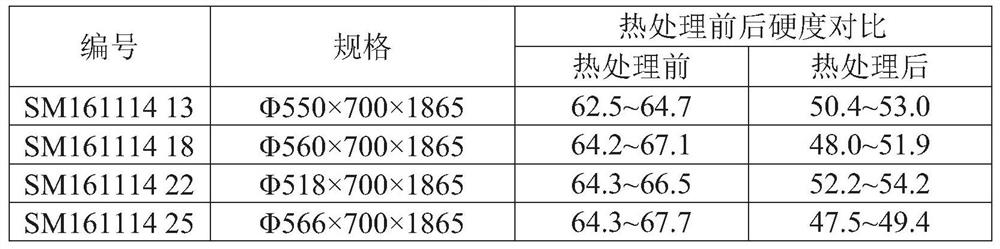

[0038] A hot-rolled section steel roll provided in this embodiment adopts the centrifugal composite bimetal casting method, with the material of grade SGA1 (GB / T1504-2008) as the outer layer and the material of grade QT500-5 (GB / T1348-2009) as the core material , The thickness of the outer layer and the core material is set accordingly according to the requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com