Preparation method for Au-ZnIn2S4 nanoarray electrode photocatalytic nitrogen fixation material

An au-znin2s4, nano-array technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low photoelectric performance, low catalytic performance, and low photoactive area, etc. To achieve the effect of loose preparation conditions, simple preparation and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

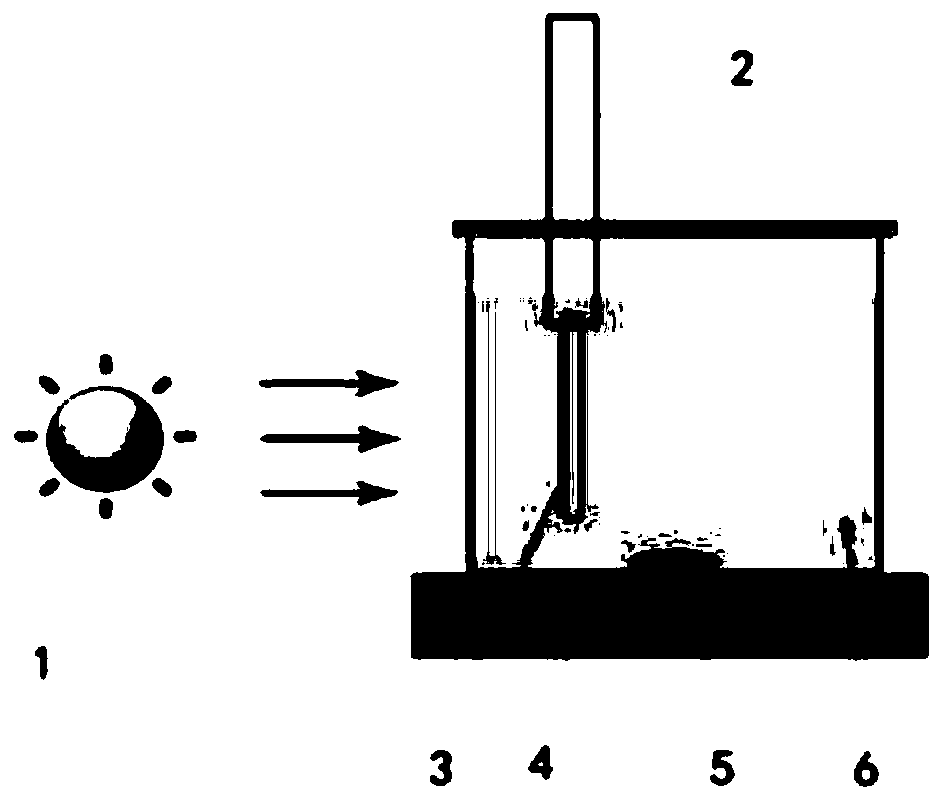

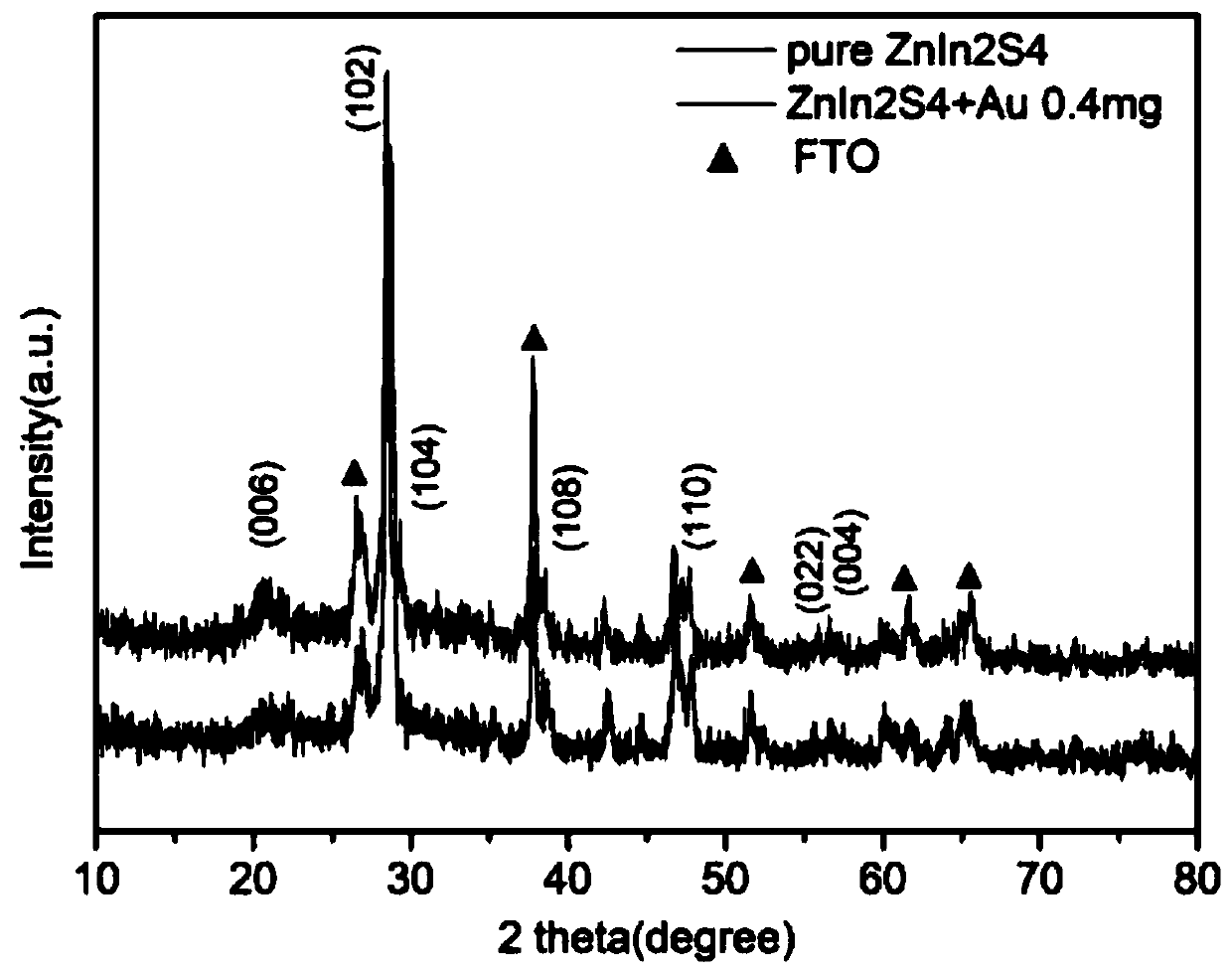

[0042] Au-ZnIn 2 S 4 The preparation method of the nano-array is: based on ZnIn 2 S 4 Photodeposition of nano-Au particles on the surface of nano-array electrodes improves ZnIn 2 S 4 Photocatalytic nitrogen fixation performance; first, a layer of ZnIn was grown on FTO conductive glass by hydrothermal method 2 S 4 Nanosheet array with Au particles deposited on its surface by photodeposition; Au-ZnIn 2 S 4 The electrode sheet was fixed in methanol aqueous solution, and high-purity nitrogen gas was fed continuously, and the N 2 Convert to NH 3 , and then converted to NH 4+ ; Take the reaction solution and Nessler's reagent for color development, and determine the NH in the reaction solution 4+ Concentration, and then determine the photocatalytic nitrogen fixation performance of the material.

[0043] The Au-ZnIn 2 S 4 The preparation of nano-arrays, the specific steps are as follows:

[0044] Step 1. Utilize zinc nitrate Zn(NO 3 ) 2 ·6H 2 O, indium trichloride In...

Embodiment 1

[0070] Embodiment 1: ZnIn with 0.2mgAu 2 S 4 Nanoarray Surface Deposition.

[0071] 1. Add 20μl of 50mmol / L AuHCl 4 Dissolve in 100mL of pure water to obtain a solution containing 0.2mg of Au, and transfer the solution into a quartz electrolytic cell.

[0072] 2. Fix the electrode sheet with a polytetrafluoroethylene electrode clip, and immerse it in the middle solution, with ZnIn 2 S 4 The surface of the nanometer film faces the xenon lamp light source, and illuminates for 30 minutes in a magnetic stirring.

[0073] 3. Take out the electrode sheet, slowly rinse it with pure water for 3 minutes, and dry it in vacuum at 60°C for 6 hours to obtain an Au-ZnIn2S4 electrode sheet with 0.2 mg of Au photodeposited.

Embodiment 2

[0074] Embodiment 2: ZnIn with 0.4mgAu 2 S 4 Nanoarray Surface Deposition.

[0075] 1. Add 40μl of 50mmol / L AuHCl 4 Dissolve in 100mL of pure water to obtain a solution containing 0.4mg of Au, and transfer the solution into a quartz electrolytic cell.

[0076] 2. Fix the electrode sheet with a polytetrafluoroethylene electrode clip, and immerse it in the middle solution, with ZnIn 2 S 4 The surface of the nanometer film faces the xenon lamp light source, and illuminates for 30 minutes in a magnetic stirring.

[0077] 3. Take out the electrode sheet, rinse it slowly with pure water for 3 minutes, and dry it in vacuum at 60°C for 6 hours to obtain Au-ZnIn with 0.4 mg Au photodeposited 2 S 4 electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com