Step-by-step controlled-release intelligent capsule, preparation method and 3D printing system

A 3D printing and capsule technology, which is applied in the field of medicine, can solve the problems of complex production process and single function, and achieve the effect of simple process, improved processing efficiency and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing the above-mentioned stepwise controlled-release smart capsule, comprising the following steps:

[0052] Step 1: Put the printing ink and the drug into the slurry tube 5-1 as slurry respectively;

[0053] Step 2: According to the structure of the step-by-step controlled-release smart capsule, use modeling software to establish a three-dimensional solid model, export the STL file and slice the step-by-step smart capsule model through the slicing software;

[0054] Step 3: Input the STL format file into the 3D printing system. After setting the parameters on the host computer 1, the parameters are preferably that the outlet diameter of the extrusion head is 0.34mm-0.6mm, and the extrusion speed is 20mm / s-30mm / s s, the filling rate is 92% to 100%, and the printing layer thickness is 0.1mm to 0.5mm; start the 3D printing system, and the pressure controller 3 controls the slurry in the slurry tube 5-1 to be extruded f...

Embodiment 1

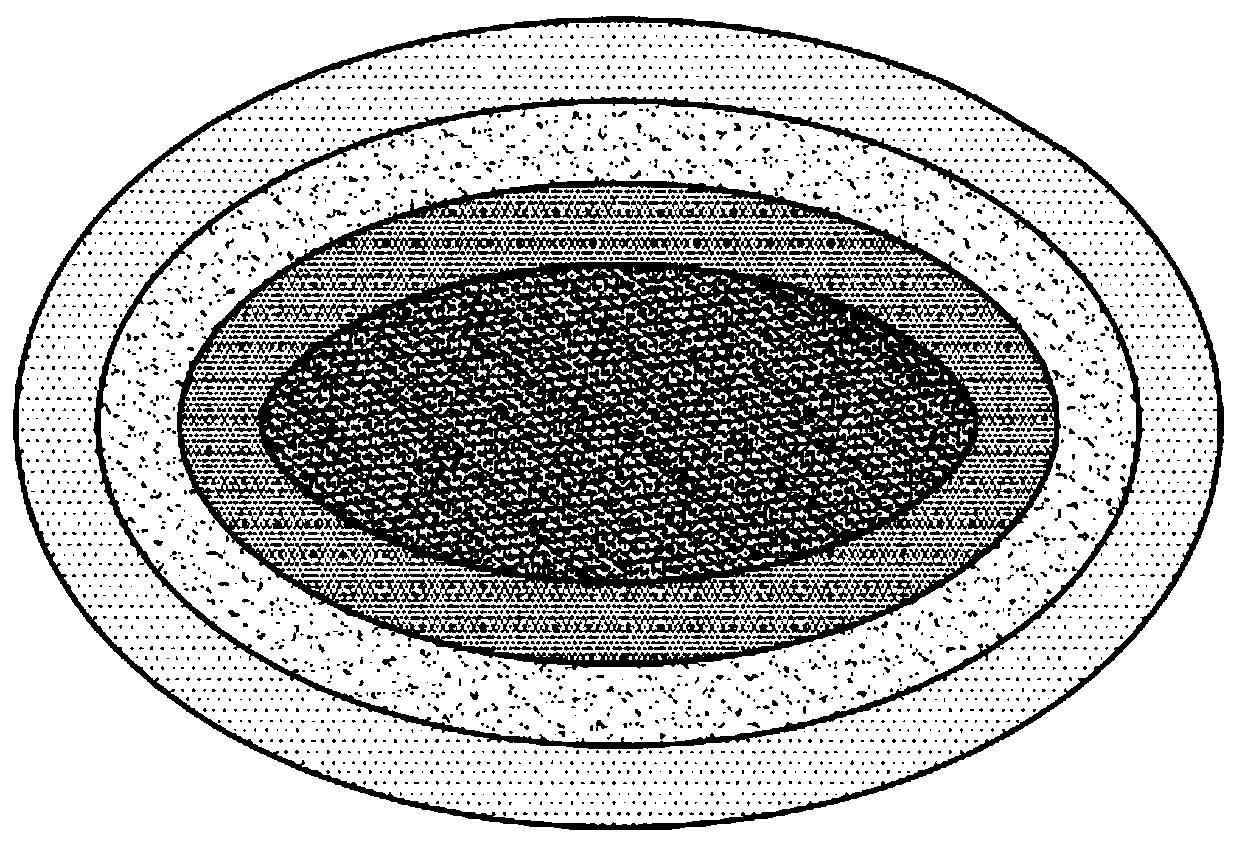

[0065] Figure 6 Schematic diagram of "onion-shaped" step-by-step controlled-release smart capsules printed for extrusion molding 3D printing technology, such as Figure 6 As shown, it specifically includes the following steps:

[0066] 1. Material preparation:

[0067] (1) Preparation of gelatin 3D printing ink: According to the mass ratio of gelatin: glycerin: water = 1:0.35:1.30, the above materials are mixed evenly, heated to 85°C in a hot water bath, and vacuum degassed under stirring to obtain Uniform glue solution, then add 0.5% (w / v) carboxylated cellulose nanofibers to the glue solution, after fully stirring, the gelatin ink of 3D printing is obtained;

[0068] (2) Preparation of sodium alginate 3D printing ink: Mix the above materials evenly with the ratio of sodium alginate: sodium carboxymethyl cellulose = 6:1 according to the mass ratio, and then use distilled water sol, the sol temperature is 55 ° C, Add polyethylene glycol solution-400 during the sol process,...

Embodiment 2

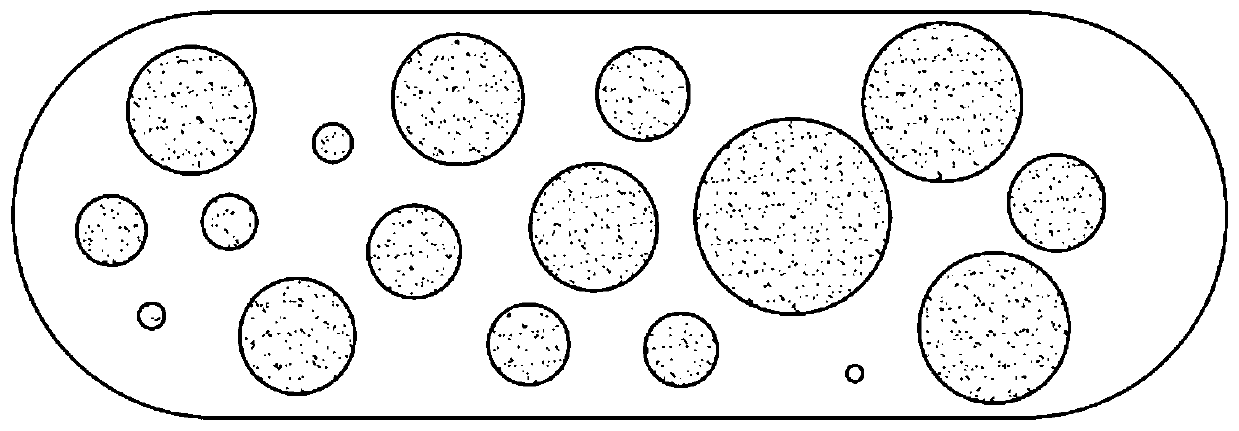

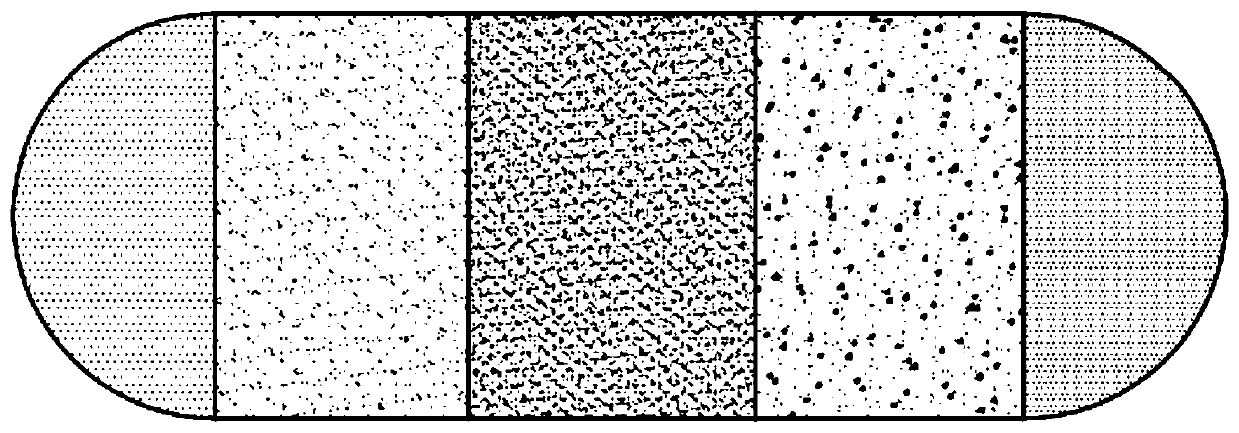

[0079] Figure 7 Schematic diagram of the process stages of printing "sugarcane-child compound type" step-by-step controlled-release smart capsules for extrusion molding 3D printing technology, Figure 8 Schematic diagram of the end stage of the "sugarcane-child compound" step-by-step controlled-release smart capsule printed by extrusion 3D printing technology, as shown in Figure 7 and Figure 8 As shown, it specifically includes the following steps:

[0080] 1. Material preparation:

[0081] (1) Preparation of gelatin 3D printing ink: According to the mass ratio of gelatin: glycerin: water = 1:0.35:1.30, the above materials are mixed evenly, heated to 85°C in a hot water bath, and vacuum degassed under stirring to obtain Uniform glue solution, then add 0.5% (w / v) carboxylated cellulose nanofibers to the glue solution, after fully stirring, to obtain gelatin ink suitable for 3D printing;

[0082] (2) Preparation of sodium alginate 3D printing ink: Mix the above materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com