Seat cover clothinspection and test platform

A testing platform and fabric technology, applied in the direction of testing wear resistance, using stable tension/pressure to test material strength, analyzing materials, etc., can solve problems such as unfavorable inspection tests, uneven fabric testing, and difficulty in obtaining compression resistance , to achieve the effect of convenient compression test and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

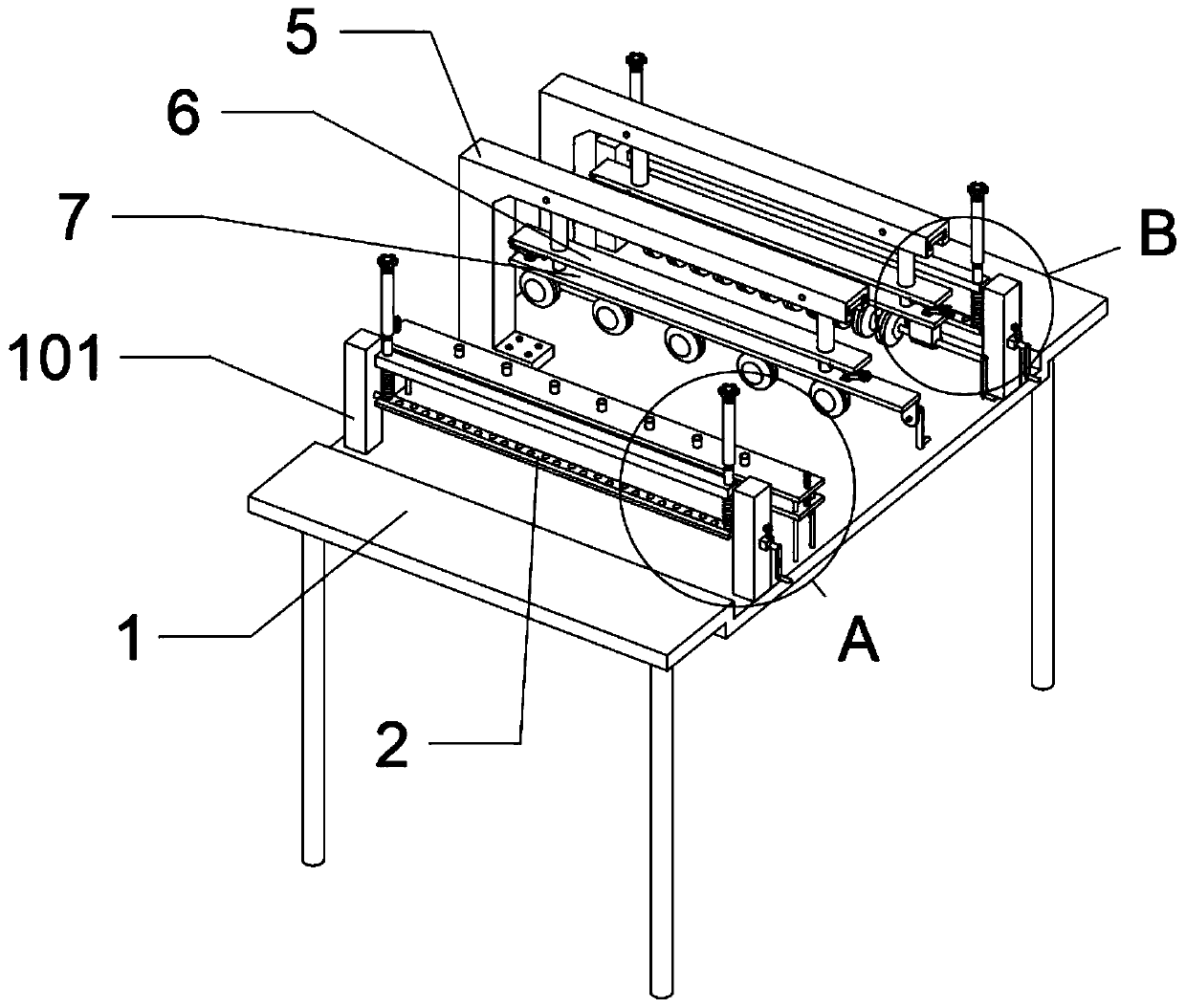

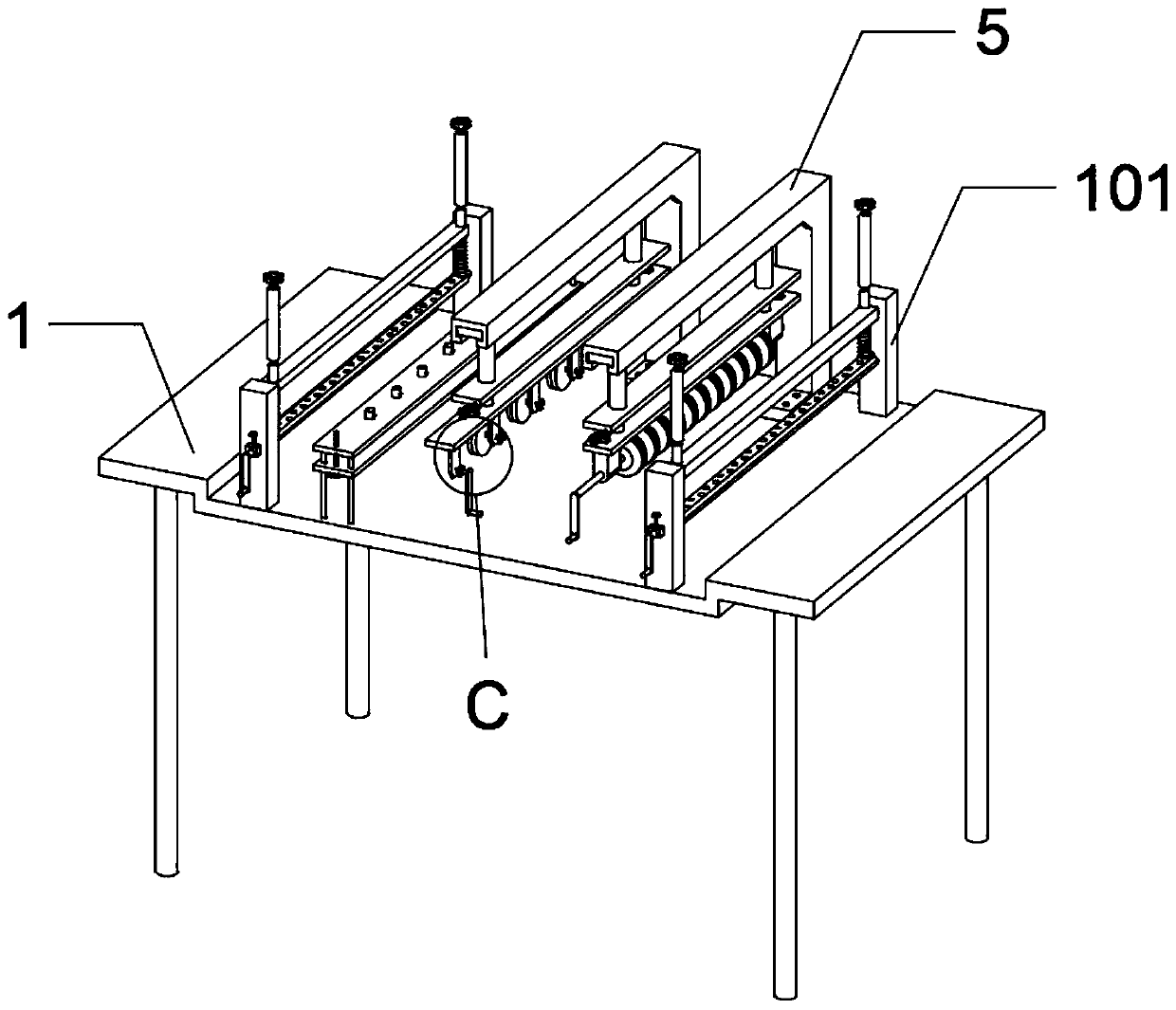

[0029] as attached figure 1 to attach Image 6 Shown:

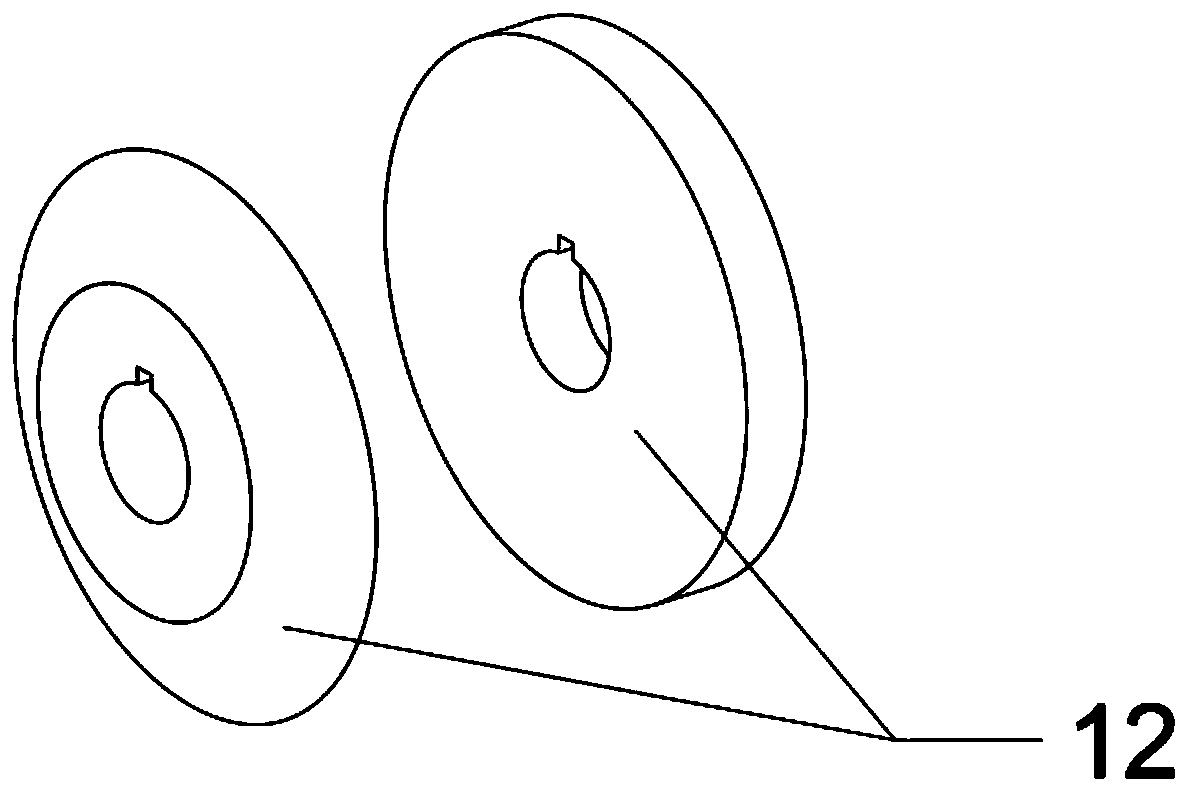

[0030] The invention provides a seat cover fabric inspection and testing platform, which includes a machine platform 1, a fabric fixing frame 101, a tightening square cylinder 102, a fixed bottom plate 2, a rocker A201, a guide rod 202, a fixed top plate 3, and a locking cylinder 4. Processing frame 5, processing conductor 6, horizontal friction frame 7, rocker B701, longitudinal friction frame 8, rotating shaft frame 801, rocker C802, lifting frame 9, air-permeable test board A10, air-permeable test board B11 and friction wheel 12; The top of the machine 1 is provided with fabric fixing frames 101 on both sides of both ends; the top side of the machine 1 is fixed with two groups of processing frames 5 by bolts, and the top and bottom sides of the processing frames 5 are provided with T-shaped Chute: The inside of the top of the processing frame 5 is fitted with a T-shaped chute and fixed with a processing conductor 6 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com